PLC how to add 4-20 correction factor sets the stage for precise industrial data acquisition. This guide delves into the crucial steps for implementing 4-20mA correction factors in Programmable Logic Controllers (PLCs), ensuring accurate readings in diverse applications. Understanding the nuances of 4-20mA current loops and their inherent susceptibility to environmental factors is paramount for achieving reliable results.

The process encompasses a detailed explanation of 4-20mA sensor types, common error sources, and the mathematical procedures for calculating correction factors. Real-world examples, case studies, and troubleshooting strategies are presented to empower readers with practical application skills.

Introduction to 4-20mA and PLC Systems

The 4-20mA current loop is a widely used standard in industrial automation for transmitting analog signals. It offers several advantages, including immunity to noise, simple wiring, and long transmission distances, making it a robust choice for many applications. This standard facilitates communication between sensors and programmable logic controllers (PLCs), enabling precise monitoring and control of various process parameters.This section provides a comprehensive overview of the 4-20mA current loop, its integration with PLCs, and the critical role of linearization and correction factors in ensuring accurate data acquisition and control.

Understanding these aspects is essential for effective implementation and troubleshooting in industrial automation systems.

4-20mA Current Loop Standard

The 4-20mA current loop is a standardized method for transmitting analog signals. A 4mA current corresponds to the lowest measurable value, while 20mA represents the highest. The signal’s current varies linearly with the measured value. This linear relationship is crucial for accurate data representation.

Typical Input Range of a 4-20mA Sensor

Sensors used with the 4-20mA current loop typically have a defined input range. This range is the physical measurement that the sensor converts into the 4-20mA signal. For instance, a temperature sensor might have a range of 0 to 100°C, while a pressure sensor might have a range of 0 to 100 PSI. The 4-20mA signal directly reflects the measured value within this input range.

PLC Interface with 4-20mA Signals

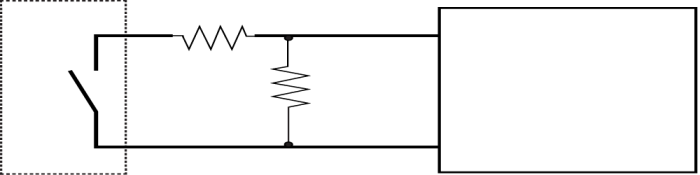

PLCs typically interface with 4-20mA signals through dedicated modules or input cards. These modules have circuitry to convert the analog current signal into a digital representation that the PLC can process. The conversion process involves sampling the current and converting it into a voltage that is proportional to the current. The digital value is then used by the PLC’s programming logic.

Linearization in 4-20mA Systems

Linearization is the process of ensuring that the relationship between the sensor’s input and the 4-20mA output is truly linear. This is critical for accurate data interpretation. Some sensors might exhibit non-linear behavior, requiring calibration or correction to maintain the linear relationship between input and output. The accuracy of the measurement depends on the effectiveness of the linearization process.

Need for Correction Factors in Real-World Applications

Real-world sensor readings are often influenced by various factors such as ambient temperature, pressure, and humidity. These factors can introduce deviations from the ideal linear relationship. Correction factors are used to compensate for these deviations and ensure accurate representation of the measured variable.

Sensor Input/Output Range Table

| Sensor Type | Input Range (mA) | Output Range (e.g., 0-100%) |

|---|---|---|

| Temperature Sensor | 4-20mA | 0-100°C |

| Pressure Sensor | 4-20mA | 0-100 PSI |

| Flow Sensor | 4-20mA | 0-1000 L/min |

Understanding Correction Factors

-20mA signals are crucial for industrial automation, transmitting data from sensors to Programmable Logic Controllers (PLCs). However, various factors can introduce errors into these signals, impacting the accuracy of the measurements. Understanding these factors and their associated correction methods is vital for ensuring reliable and precise data acquisition.Environmental conditions, sensor characteristics, and transmission issues can all contribute to inaccuracies in 4-20mA signals.

Correcting for these errors is essential for accurate process control and decision-making in industrial settings. The accuracy of a measurement depends not only on the sensor itself, but also on the surrounding conditions and the methodology used to account for the errors.

Sources of Error Affecting 4-20mA Signals

Various factors can affect the accuracy of 4-20mA signals. These include sensor aging, variations in environmental conditions, and signal transmission problems.

- Sensor Drift and Aging: Sensors, like any component, degrade over time. This leads to gradual changes in their output, impacting the accuracy of the 4-20mA signal. This drift can be a result of internal component degradation, or the influence of environmental factors like temperature and humidity.

- Environmental Factors: Temperature, pressure, and humidity are significant sources of error. For instance, a temperature sensor might produce an inaccurate reading if the ambient temperature deviates significantly from its calibrated range. Similarly, pressure fluctuations can affect pressure sensors, while humidity can impact moisture-sensitive sensors. These deviations need to be carefully considered and corrected.

- Signal Transmission Issues: Signal attenuation, noise, and cable resistance during transmission can introduce errors into the 4-20mA signal. Longer cable lengths, poor cable quality, and interference from other electrical signals can cause these problems. These factors need to be accounted for during the design and implementation phases of the system.

Types of Correction Factors

Various correction factors are applied to compensate for the errors introduced by different environmental influences.

- Temperature Correction: Temperature is a prevalent factor influencing sensor readings. A temperature sensor might produce a higher output for a given temperature if the ambient temperature is higher than the calibration temperature. Correction factors often account for these differences by using a calibration curve or a mathematical model relating sensor output to temperature.

- Pressure Correction: Pressure changes can significantly affect the readings of pressure sensors. For instance, a pressure sensor might output a higher value for a given pressure if the ambient pressure is higher than the calibration pressure. Correction factors are used to account for these variations.

- Humidity Correction: Humidity can affect moisture-sensitive sensors. A humidity sensor might provide inaccurate readings in environments with high or low humidity levels. Calibration curves or mathematical models are often used to correct for these errors.

Examples of Environmental Influence on Sensor Readings

Environmental conditions have a significant impact on sensor accuracy.

- Temperature Impact on Resistance Thermometers: A resistance thermometer used to measure temperature might exhibit a higher resistance reading if the ambient temperature is higher than the calibration temperature. This deviation from the calibrated value needs to be accounted for to ensure accurate temperature measurement.

- Pressure Impact on Pressure Sensors: A pressure sensor might give a higher output for a given pressure if the ambient pressure is higher than the calibration pressure. The resulting measurement error requires appropriate correction.

Importance of Calibration, Plc how to add 4-20 correction factor

Calibration is critical for ensuring the accuracy of 4-20mA signals. Calibration procedures provide a baseline for comparison, enabling the identification and correction of errors.

- Establishing a Baseline: Calibration establishes a reference point for the sensor’s output under specific environmental conditions. This allows for comparison with subsequent measurements, enabling the detection of any deviations and the application of appropriate correction factors.

- Identifying Errors: Calibration helps in identifying systematic errors in the sensor’s readings. This is crucial for ensuring that measurements are accurate and reliable.

Comparison of Correction Factor Methodologies

Different methodologies are employed for correcting 4-20mA signals.

| Methodology | Description | Advantages | Disadvantages |

|---|---|---|---|

| Linear Interpolation | Uses a linear equation to estimate the correction factor. | Simple to implement. | Less accurate for significant deviations from the calibration range. |

| Polynomial Interpolation | Uses a polynomial equation to estimate the correction factor. | More accurate than linear interpolation. | More complex to implement. |

| Lookup Tables | Pre-calculated correction factors stored in a table. | Fast and straightforward. | Limited accuracy based on the table resolution. |

Implementing Correction Factors in PLC Programming

Applying correction factors to sensor readings in Programmable Logic Controllers (PLCs) is crucial for accurate process control. Inaccurate readings, stemming from various sensor characteristics or environmental influences, can lead to suboptimal performance or even system failures. Implementing these corrections within the PLC program ensures the system responds to the actual process conditions rather than flawed sensor data.Accurate control systems rely on precise data.

By incorporating correction factors into the PLC program, the controller accounts for sensor inaccuracies, leading to more reliable and efficient operations. This enhanced accuracy translates to improved product quality, reduced waste, and enhanced safety within industrial processes.

Typical Steps in Applying a Correction Factor

Implementing a correction factor in a PLC program involves several key steps. First, identify the source of the error in the sensor readings. Next, determine the appropriate correction formula based on the nature of the error. This formula typically involves mathematical operations, often incorporating variables representing the sensor output, environmental factors, or other relevant data. Finally, incorporate the correction formula into the PLC program, ensuring its integration with existing control logic.

Calculating Correction Factors Based on Sensor Data

Correction factors are often calculated using a combination of sensor readings and known parameters. This calculation can involve various mathematical operations. For example, a linear relationship between sensor output and the actual process variable might be represented as:

Corrected Value = Sensor Output

Gain + Offset

where Gain and Offset are calculated from calibration data. The process often involves collecting data from the sensor under various known conditions, generating a calibration curve, and deriving the Gain and Offset values.

Offset and Gain Adjustment

Offset and gain adjustments are fundamental components of implementing correction factors. Offset represents a constant value that needs to be added or subtracted from the sensor reading. Gain represents a multiplicative factor that scales the sensor reading. Adjusting these parameters fine-tunes the sensor output to accurately reflect the process variable.

Flow Chart Illustrating the Process of Applying a Correction Factor

[Insert a flow chart here. The flow chart should begin with a PLC receiving sensor data. It should then branch to calculate the correction factor based on the sensor reading and known parameters. Then, it should apply the correction factor, adjusting the offset and gain as needed. Finally, the corrected value should be used in the control logic.]The flow chart visually represents the sequence of operations from sensor input to output correction, clearly showing the stages of calculation and application.

PLC Programming Languages and Correction Factor Implementation Examples

| Programming Language | Example Implementation (Conceptual) |

|---|---|

| Ladder Logic |

A rung in the ladder logic program would read the sensor input, calculate the correction factor (using a function block or separate calculations), and then output the corrected value to a register. |

| Structured Text (ST) |

In ST, a function or function block would encapsulate the correction factor calculation, taking the sensor input as input and returning the corrected value. This function could be called within the main control logic.

|

The table demonstrates that various PLC programming languages offer different approaches to implementing correction factor calculations. The choice of language depends on the specific PLC system and the programmer’s familiarity with each language.

Practical Examples and Case Studies

Applying correction factors to 4-20mA sensor data is crucial for accurate measurements in various industrial settings. These factors account for variations in sensor performance, environmental conditions, and measurement techniques. Understanding and implementing these factors ensures reliable data interpretation and efficient process control.Implementing correction factors in a PLC system significantly enhances the reliability and accuracy of the acquired data.

This process involves identifying the relevant correction factors for the specific sensor and environment, incorporating these factors into the PLC program, and validating the results against known values.

Temperature Sensor Example

A temperature sensor, commonly used in industrial processes, often exhibits a non-linear response to temperature changes. A 4-20mA output signal from a temperature sensor needs to be corrected for this non-linearity. Consider a sensor with a known offset and gain error. If the sensor output at 25°C is 10mA, and the output at 50°C is 18mA, the sensor’s response is not directly proportional.

A correction factor is required to map the 4-20mA signal to the actual temperature. The PLC program needs to incorporate this correction factor into the calculations, ensuring the displayed temperature is accurate, regardless of the sensor’s output.

Different Sensor Types and Correction Factors

Different sensor types have different correction factors. The table below Artikels common scenarios:

| Sensor Type | Typical Error Source | Correction Factor Application |

|---|---|---|

| Thermocouple | Temperature of the junction, wire resistance, and material properties | Calibration curves and tables, or mathematical models, are often used to correct for the various sources of error |

| RTD (Resistance Temperature Detector) | Ambient temperature, wire resistance, and lead resistance | Mathematical formulas or lookup tables are typically used to compensate for these errors. |

| Strain Gauge | Temperature variations, environmental conditions, and mechanical stress | Calibration curves or mathematical models are essential to adjust for the strain and the environmental conditions. |

| Flow Meter | Fluid viscosity, pipe diameter, and pressure variations | Correction factors are based on empirical data or theoretical models to account for fluid properties and system parameters. |

Case Study: Improved Data Accuracy in a Chemical Reactor

In a chemical reactor application, temperature readings from thermocouples were inaccurate without correction factors. The process used thermocouples to monitor reaction temperatures. Without correction factors, the temperature readings varied significantly from the expected values, leading to inefficiencies in the process. Implementing correction factors, derived from the thermocouple calibration curve and environmental data (ambient temperature), significantly reduced the error in the temperature readings.

This led to improved control of the reaction parameters and optimized yield, resulting in a substantial cost savings.

Calculating the Correction Factor

The correction factor calculation depends on the specific sensor and application. For a temperature sensor, the correction factor is often a function of the temperature difference between the sensor and the reference temperature. For instance, a formula could be used to account for the change in resistance of the sensor with temperature. A mathematical model, based on the sensor’s characteristics and the environment, can help to determine the appropriate correction factor.

Correction factor = (Measured Value – Expected Value) / Expected Value

Advantages of Applying Correction Factors

Applying correction factors improves the accuracy of data acquisition, which leads to:

- Enhanced process control: Accurate data enables better control of processes, reducing variability and improving efficiency.

- Improved product quality: Precise measurements lead to better control over manufacturing processes, resulting in higher quality products.

- Reduced maintenance costs: Early detection of issues through accurate measurements allows for timely maintenance and avoids costly equipment failures.

- Increased profitability: Improved process efficiency and product quality contribute to higher profitability.

Common Mistakes in Implementing Correction Factors

Common mistakes include:

- Incorrect selection of correction factors: Choosing the wrong correction factor for the sensor and environment can lead to inaccurate results.

- Ignoring environmental factors: Factors like ambient temperature, pressure, and humidity can significantly affect sensor readings, and neglecting these factors can result in inaccurate correction.

- Insufficient calibration: Inadequate calibration of the sensor can lead to errors in the correction factors, which in turn affect the accuracy of the data.

- Lack of validation: Without validating the corrected data against known values, it’s difficult to ascertain the accuracy of the correction.

Advanced Considerations

Applying correction factors to 4-20mA sensor readings in PLC systems requires careful consideration of various factors beyond basic calculations. Understanding the potential impact of sensor aging, different calculation methods, and the nuances of application selection is crucial for accurate and reliable data acquisition. This section delves into these advanced aspects, highlighting the importance of data validation and the risks associated with incorrect factor application.Accurate 4-20mA signal interpretation relies on the maintenance of stable sensor performance.

The inherent limitations of real-world systems demand a deeper understanding of the dynamic nature of these corrections. Addressing these issues with appropriate strategies is essential for industrial processes.

Impact of Sensor Aging on Correction Factors

Sensor performance degrades over time due to factors like material fatigue, environmental exposure, and internal component wear. This degradation can significantly alter the sensor’s output, affecting the accuracy of the correction factors. Regular recalibration and monitoring of sensor performance are vital to maintaining data integrity. In some cases, a correction factor might need to be adjusted periodically based on sensor age and usage history.

This ensures that the correction factor remains effective over the sensor’s operational lifetime. Failure to account for sensor aging can lead to inaccurate process control, resulting in decreased efficiency and potential safety hazards.

Comparison of Different Correction Factor Calculation Methods

Various methods exist for calculating correction factors, each with its own strengths and weaknesses. Linear interpolation, polynomial fitting, and statistical regression are common techniques. The choice of method depends on the nature of the sensor output relationship with the measured variable. For instance, linear interpolation is suitable for sensors exhibiting a near-linear relationship, while polynomial fitting might be necessary for more complex curves.

Statistical regression can be used to model the relationship between the sensor output and the measured variable with consideration of measurement errors. Careful evaluation of the data and the characteristics of the sensor are necessary for choosing the most appropriate method.

Choosing the Appropriate Correction Factor Based on the Specific Application

The selection of the appropriate correction factor is critical for accurate data interpretation. Factors like the specific sensor type, operating environment, and expected range of measurement values all play a role. Consideration must be given to the degree of precision required for the application. For instance, a process requiring high precision, such as in pharmaceutical production, would necessitate a more sophisticated correction factor calculation than a general-purpose process control application.

Comprehensive testing and validation are essential for ensuring the correction factor accurately reflects the specific application’s needs.

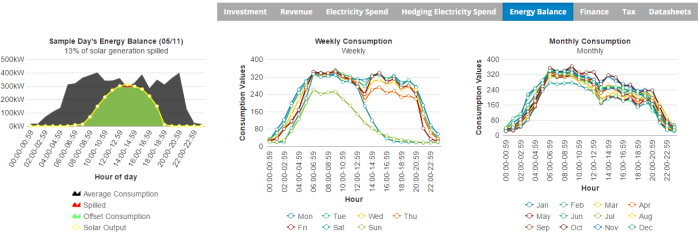

Importance of Data Validation After Applying Correction Factors

Data validation is crucial after applying correction factors. This involves checking for inconsistencies, outliers, and unexpected trends in the corrected data. Discrepancies might indicate issues with the correction factor itself, the sensor, or the data acquisition system. Thorough analysis of the validated data can help identify potential problems early and prevent costly errors or safety hazards. Visualizations of the data, including graphs and histograms, can be beneficial for identifying patterns and trends.

Potential Risks of Applying Incorrect Correction Factors

Applying incorrect correction factors can lead to significant issues. Inaccurate readings can result in improper control of the process, potentially leading to reduced efficiency, product defects, or safety concerns. In extreme cases, the incorrect factor may cause dangerous operational conditions. The risk of applying an incorrect correction factor is directly proportional to the severity of the process being controlled.

Table of Different Sensor Types and Typical Correction Factors

| Sensor Type | Typical Correction Factors | Notes |

|---|---|---|

| Temperature Sensors (Thermocouples) | Factors related to temperature-dependent material properties, wire resistance, and junction potential. | Calibration frequently needed due to temperature dependence. |

| Pressure Sensors (Strain Gauge) | Factors related to temperature, humidity, and material properties of the sensing element. | Factors change based on the specific type of strain gauge. |

| Flow Sensors (Turbine) | Factors related to viscosity, density, and temperature of the fluid being measured. | Correction factors are often highly specific to the fluid type. |

| Level Sensors (Ultrasonic) | Factors related to temperature, ambient pressure, and sensor-to-target distance. | Factors can be significantly affected by air density variations. |

Troubleshooting and Maintenance: Plc How To Add 4-20 Correction Factor

Maintaining accurate 4-20mA readings and ensuring the reliability of PLC systems incorporating correction factors requires a proactive approach to troubleshooting and maintenance. Regular checks and prompt identification of issues prevent costly downtime and ensure consistent data integrity. This section details strategies for identifying and resolving common problems related to sensor calibration and correction factor implementation within PLC systems.

Common Troubleshooting Issues

Addressing potential problems in 4-20mA systems with correction factors requires a systematic approach. Errors can stem from various sources, including sensor malfunction, wiring issues, or improper PLC programming. A methodical troubleshooting process is crucial for pinpointing the root cause and restoring accurate readings.

Identifying Sensor Calibration Issues

Accurate sensor calibration is fundamental for reliable 4-20mA readings. Deviation from expected calibration can introduce errors into the correction factor calculations, leading to inaccurate data. Techniques for verifying sensor calibration include using a calibrated multimeter to check the output signal at known input values. Discrepancies between the expected and measured output indicate calibration issues that need immediate attention.

Troubleshooting PLC Programming Errors

Incorrect PLC programming can significantly impact the accuracy of correction factors. Reviewing the PLC program for errors in the calculation of the correction factor is a critical step. Debugging the PLC code to identify and resolve any errors is essential for accurate results. Consider using a PLC simulator to test the program and identify potential issues before implementing it in a live system.

Regular Maintenance of 4-20mA Systems

Regular maintenance of 4-20mA systems and their associated correction factors is essential for maintaining accuracy and preventing potential issues. Regular checks of sensor connections, cabling, and signal integrity help avoid unforeseen problems. Documentation of calibration dates and any maintenance performed is critical for tracking the performance of the system over time. Periodically recalibrating sensors and updating correction factors based on the latest calibration data is also essential.

Maintenance Best Practices for Accurate Sensor Readings

Maintaining accurate sensor readings involves several best practices. Implementing proper grounding techniques minimizes noise and interference, ensuring consistent sensor output. Regular inspection of wiring for damage or corrosion helps maintain signal integrity. Keeping detailed records of maintenance activities, calibration data, and any troubleshooting steps taken is crucial for future reference and problem resolution. This comprehensive approach helps ensure the long-term reliability and accuracy of the system.

Table of Potential Problems and Solutions

| Potential Problem | Possible Solution |

|---|---|

| Sensor output signal outside the 4-20mA range | Verify sensor connections, check for wiring issues, and recalibrate the sensor. |

| Inconsistent sensor readings | Inspect sensor mounting, check for environmental factors affecting the sensor, and re-calibrate. |

| PLC program errors in correction factor calculation | Review PLC code, debug the program, and validate the correction factor algorithm. |

| Incorrect wiring connections | Verify all wiring connections, identify any damaged wires, and ensure proper grounding. |

| Noise interference on the 4-20mA signal | Implement shielding measures for the signal cables, improve grounding, and identify sources of electromagnetic interference. |

Last Recap

In conclusion, accurately incorporating 4-20mA correction factors in PLC programming is essential for achieving reliable and precise data in industrial settings. This comprehensive guide provides a robust framework for understanding and implementing these factors, covering everything from fundamental concepts to advanced considerations. By understanding the factors influencing sensor readings and the steps for implementing correction, operators can enhance the reliability and accuracy of their industrial processes.

FAQ Insights

What are the most common sources of error in 4-20mA signals?

Common sources of error include temperature fluctuations, pressure variations, humidity changes, sensor aging, and variations in the sensor’s inherent characteristics. Calibration errors and incorrect installation can also contribute to inaccuracies.

How do I choose the right correction factor for my specific application?

The selection process involves identifying the specific environmental factors impacting the sensor, consulting sensor datasheets for typical correction factors, and potentially conducting field tests to determine the most suitable correction method.

What are the potential risks of applying incorrect correction factors?

Applying incorrect correction factors can lead to inaccurate readings, faulty process control, equipment malfunctions, and ultimately, financial losses due to operational inefficiencies and potential safety hazards.

How do I troubleshoot issues with sensor calibration and correction?

Troubleshooting involves checking sensor connections, verifying sensor calibration, reviewing PLC programming for errors, and evaluating environmental conditions affecting the sensor. Comparison with historical data and sensor manufacturer guidelines is often helpful.