How to replace abs module is a crucial skill for any vehicle owner. This intricate system, vital for safe braking, often requires professional attention. Understanding the mechanics behind this module, from its function to its precise location within your vehicle, is key to a successful replacement. This guide breaks down the process step-by-step, from initial diagnosis to post-installation checks, ensuring a thorough and informative experience.

The Anti-lock Braking System (ABS) module is a critical component in modern vehicles. It controls the braking system, preventing wheel lockup during hard braking. A malfunctioning ABS module can lead to unsafe braking, and in severe cases, complete brake failure. This guide will walk you through every aspect of the replacement process, emphasizing safety and efficiency.

Introduction to ABS Modules

A whisper of the unseen, a silent guardian within the metal heart of your vehicle. The Anti-lock Braking System (ABS) module is a crucial component, often overlooked, yet essential for safety. It’s a sophisticated electronic brain that monitors and controls the braking system, preventing wheel lock-up during sudden stops. Imagine a car spinning out of control; this is precisely what the ABS module prevents.The ABS module’s intricate dance of calculations and commands ensures a controlled stop, even on slick or uneven surfaces.

It’s a silent sentinel, tirelessly working behind the scenes, making sure your journey remains safe and predictable. The module’s function is not limited to just preventing skidding; it also assists in maintaining directional control.

Typical Signs of Malfunction

The ABS module, like a silent sentinel, often reveals its struggles through subtle but telling signs. A common indication of trouble is a flashing warning light on your dashboard, often accompanied by a rhythmic pulsing or a steady illumination. Other telltale symptoms include a noticeable delay in braking response, a grinding or pulsating sensation when braking, or the vehicle exhibiting an erratic or unresponsive behavior.

These symptoms can range from subtle hints to more pronounced disruptions in the vehicle’s operation.

Common Reasons for Replacement

Several factors can lead to the need for an ABS module replacement. A significant electrical surge or power spike, often resulting from a short circuit or a faulty component, can damage the module’s sensitive electronics. Water intrusion, particularly in vehicles exposed to harsh weather conditions, can also corrode the internal components and disrupt their functions. Further, collisions, especially those involving the front end, can impact the module, leading to mechanical failure.

In rare instances, a defective or aging module can simply malfunction over time, much like an old clock winding down.

Importance of Proper Replacement

Replacing an ABS module requires meticulous attention to detail and adherence to proper procedures. A faulty replacement or an improper installation can lead to a cascade of problems, ranging from poor braking performance to erratic vehicle behavior. Correct installation is crucial to ensure the module’s integration with the existing vehicle systems, preventing potential malfunctions and maintaining the safety of the driving experience.

It’s akin to repairing a complex puzzle; one wrong piece can disrupt the entire image.

Components and Potential Issues

| Component Name | Description | Potential Issues |

|---|---|---|

| ABS Control Unit | The primary brain of the ABS system. | Electrical surge damage, water intrusion, mechanical stress. |

| Hydraulic Valves | Control the brake pressure to each wheel. | Corrosion, malfunction, damage from collisions. |

| Sensors | Monitor wheel speed and braking conditions. | Malfunction, damage from impact or debris. |

| Wiring Harness | Connects all components. | Damage, corrosion, short circuits. |

Identifying the ABS Module

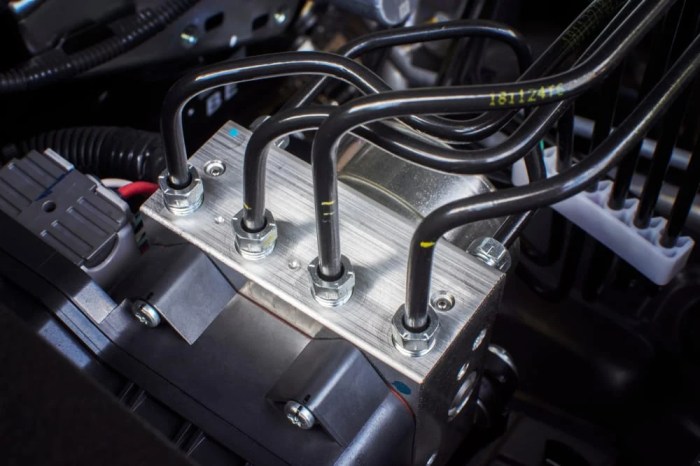

A whisper of the unseen, a phantom in the mechanical heart of your vehicle. The Anti-lock Braking System (ABS) module, a silent guardian of your safety, resides within the depths of your car’s intricate architecture. Locating it requires a keen eye and a little bit of knowledge about the silent language of your vehicle. This knowledge will be your guide to navigate the mechanical labyrinth and uncover the module’s hidden sanctum.The ABS module, often a compact black box or a slightly larger, rectangular unit, serves as the brain of the braking system.

Its physical characteristics, while varying by make and model, typically include electronic components, wiring connections, and a unique identification number, allowing you to confirm its authenticity and functionality. This task of identification is not as straightforward as it seems. Understanding its placement within your vehicle’s chassis, its subtle differences across generations, and the specific access points, is crucial for safe and efficient replacement.

Physical Characteristics of an ABS Module

The ABS module, often a rectangular or slightly irregular box, is typically constructed of durable, heat-resistant plastic or metal. Its size and shape are dependent on the vehicle’s specifications and the complexity of the ABS system. Electronic components, like integrated circuits and transistors, are often visible on the module’s surface, or perhaps hidden beneath a protective cover. Wiring harnesses and connectors are attached to the module, enabling its communication with other components in the braking system.

Identifying the module requires close attention to these details.

Locating the ABS Module in Various Vehicle Types

Locating the ABS module varies significantly between car, truck, and SUV models. The module’s position is determined by the vehicle’s design and the arrangement of its mechanical components. Often, the module is strategically placed in a compartment that is readily accessible, but sometimes, it requires removing panels or components to gain access.

ABS Module Location Table

| Vehicle Make/Model | ABS Module Location | Access Points |

|---|---|---|

| Toyota Camry (2015) | Under the dashboard, near the steering column | Remove the lower dashboard panel |

| Ford F-150 (2018) | Under the hood, near the engine | Remove the engine cover and associated brackets. |

| Honda CR-V (2020) | Under the driver’s side of the center console | Remove the center console and the associated panels. |

| Chevrolet Silverado (2022) | Behind the glove box, on the passenger side | Remove the glove box and surrounding panels. |

Procedure for Identifying the ABS Module in a Specific Vehicle Make and Model

A meticulous approach is essential when identifying the ABS module. This method guarantees that you will identify the right part. Refer to your vehicle’s owner’s manual or a reliable online resource. The manual will provide a precise diagram of the ABS module’s location and access points. Carefully review the diagram and note any specific procedures or cautions.

Once you locate the module, verify its appearance, size, and any identification markings. This step helps to prevent errors.

Differences in ABS Module Locations Between Different Vehicle Generations

Vehicle manufacturers often update and improve their ABS systems over time, resulting in slight variations in module placement across different generations of the same vehicle model. For example, the 2010 Honda Civic may have the ABS module positioned differently compared to the 2023 model. This difference in placement could be due to design changes or upgrades to the braking system.

Careful attention to the specific year and model of the vehicle is vital.

Tools and Materials Required

A whisper of the dark side of the automotive world, a shadowy realm where intricate mechanisms and unseen forces dance. Replacing the ABS module is not for the faint of heart, or those who shy away from the unknown. This task requires a precise touch, a keen eye, and a deep understanding of the silent language of the machine.

Prepare yourself, for the path ahead is paved with both tools and trepidation.The replacement of an ABS module demands meticulous attention to detail and a firm grasp of safety protocols. The intricate network of wires and sensors within the module holds the key to your vehicle’s braking system. Any misstep could lead to unforeseen consequences, from minor inconveniences to potentially dangerous situations.

Comprehending the necessary tools and materials is paramount to a successful and safe replacement.

Essential Tools

Careful consideration must be given to the selection of tools, each a silent guardian in this delicate operation. Improper tools can damage components, potentially leading to more problems than they solve. A well-equipped toolbox is the first line of defense against unforeseen complications.

- Torque wrench: A precise instrument for tightening bolts and nuts to the manufacturer’s specifications. Failure to use a torque wrench can lead to stripped bolts or components that are either under or over-torqued, potentially compromising the entire system.

- Screwdrivers (Phillips and flathead): A necessity for disassembling various components. Different sizes and types are needed to accommodate the various fasteners used within the ABS module assembly.

- Pliers: Used for gripping and manipulating parts during the process. Correctly using pliers is crucial to avoid damage to delicate components.

- Wire strippers: Essential for safely detaching and connecting wires. Careful attention to wire sizes and types is needed to avoid electrical issues.

- Multimeter: For testing electrical circuits and ensuring proper function. This tool is vital for confirming the module’s connections are intact and functioning correctly. A malfunctioning module can lead to braking issues.

Safety Precautions

Safety is paramount in any automotive repair. Failure to observe safety protocols can lead to injury, damage to the vehicle, or even worse. A moment’s lapse in concentration can have serious repercussions.

- Wear appropriate personal protective equipment (PPE): Safety glasses, gloves, and a sturdy work apron protect you from potential hazards during the procedure.

- Disconnect the vehicle’s battery: This crucial step prevents accidental electrical shocks and safeguards against any electrical malfunction during the process.

- Work in a well-ventilated area: Ensure adequate airflow to avoid inhaling fumes and maintain optimal working conditions.

- Take breaks as needed: Maintain focus and prevent fatigue, which can lead to mistakes and errors.

- Consult the vehicle’s repair manual: This manual contains detailed instructions specific to your vehicle, which should be followed meticulously.

Materials Required

The replacement process demands a specific set of materials to ensure a successful and flawless outcome.

- New ABS module: This is the heart of the system. Choosing a reputable brand and ensuring the correct part number is crucial to avoid compatibility issues.

- Connectors and wiring: Ensuring the correct connectors and wiring are used is vital for electrical connections. Incorrect connections can lead to system malfunctions.

- Special lubricants: Specific lubricants may be needed for certain components to ensure smooth operation and prevent damage.

- Sealant: Using sealant where necessary helps prevent leaks and ensure proper sealing.

- Gaskets: Gaskets are used in some situations to provide a waterproof and airtight seal, ensuring that components are correctly assembled.

Comparison of Tools

Different tools have specific uses and advantages in automotive repairs.

| Tool | Description | Advantages |

|---|---|---|

| Torque Wrench | Precisely tightens bolts to manufacturer’s specifications | Prevents over-tightening or under-tightening, maintaining component integrity |

| Screwdrivers | Disassembles components by turning screws | Effective for removing and installing various fasteners |

| Pliers | Grips and manipulates components | Essential for handling and positioning parts during assembly |

Vehicle Preparation

Thorough preparation is the key to a smooth and successful ABS module replacement.

- Gather all necessary tools and materials: Ensure you have everything before starting the procedure to avoid interruptions and delays.

- Park the vehicle on a level surface: This ensures stability and prevents accidents during the replacement process.

- Locate the ABS module: Identify the module’s location and understand its connections.

- Disconnect the vehicle’s battery: Prevent electrical shocks and ensure safety during the procedure.

Replacement Procedure

The whispers of the engine bay, a symphony of metallic groans and silent hums, often hold secrets of the vehicle’s inner workings. One such secret, guarded by a cryptic electronic brain, is the Anti-lock Braking System (ABS) module. Replacing it is like unraveling a complex puzzle, requiring meticulous attention to detail and a touch of ghostly precision. Mistakes can be costly, and the spectral silence of a faulty system can be unnerving.

Disconnecting the ABS Module

Before dismantling the ABS module, safety is paramount. The vehicle’s electrical system, a labyrinth of interconnected circuits, must be safely severed from the module. Incorrect disconnection can lead to unexpected electrical surges, potentially damaging sensitive components. The precise procedure involves locating the relevant connectors and using appropriate tools for disconnecting them, ensuring a clean break. This step requires a keen eye for detail and a practiced hand.

Removing the Old ABS Module

The old ABS module, a silent sentinel of the past, must be extracted from its housing. This procedure involves carefully disconnecting any mounting hardware and securing the module for safe removal. Potential obstacles may include stubborn fasteners or complex wiring harnesses. Care must be taken to avoid damaging the module or any adjacent components. This task demands precision and a steady hand.

Installing the New ABS Module

Installing the new ABS module is a delicate dance of precision and care. The procedure involves meticulously positioning the module in its housing, ensuring proper alignment. This is where the knowledge of the specific vehicle’s layout becomes critical. All wiring harnesses must be meticulously connected, ensuring a secure and proper electrical contact. Any loose connections could lead to intermittent failures or worse.

Connecting Wires and Components

Connecting the wires and components is crucial. Each wire must be precisely inserted into its corresponding connector, ensuring a solid and secure connection. This is a crucial step to avoid electrical issues. Inspect all connections meticulously. A single misaligned wire can lead to a system malfunction.

Use appropriate tools to ensure a clean connection and avoid any damage to the wires or connectors.

Secure Connection and Handling

Ensuring a secure and proper connection is paramount. Every connection must be tested for tightness and integrity. Improper connection can lead to electrical issues. Proper handling is crucial to prevent damage to the new module. Carefully secure all mounting hardware and components to prevent any movement during operation.

The module should be handled with utmost care to avoid scratches or damage to its sensitive components. Any damage can lead to a malfunctioning ABS system.

Best Practices for Installation

Thoroughness is key. Double-check every connection to ensure a reliable and stable system. Document the procedure for future reference. Consult the vehicle’s repair manual for specific instructions and warnings. Maintain a meticulous approach, from disconnecting the module to securing it in its housing.

The system’s functionality depends on the care taken during installation. Thoroughness and attention to detail are the hallmarks of a successful replacement.

Troubleshooting and Testing

A whisper of a malfunction, a subtle groan from the depths of the undercarriage—the ABS module, silent guardian of your wheels, can sometimes betray its trust. Like a phantom limb, its absence can leave you adrift, unsure of the car’s true intentions. But fear not, intrepid mechanic, for with careful attention and a touch of detective work, we can unravel the mystery of a faulty ABS module.The replacement of the ABS module, while often straightforward, can present unforeseen challenges.

Potential problems can range from simple installation errors to more complex issues within the module itself. The following sections Artikel the critical steps in diagnosing and rectifying these problems, transforming the unsettling unknown into a clear path to a functioning system.

Potential Problems During Replacement

Several issues can crop up during the replacement procedure. Improper handling of electrical connections, for example, can lead to short circuits or intermittent failures. Incorrect torque settings during the tightening of mounting bolts can result in loose connections or, worse, a catastrophic failure. A lack of attention to detail can lead to issues that are difficult to track down later.

Testing Procedures for Proper Functioning

Verification of the new ABS module’s functionality is paramount. A simple but thorough test involves activating the brakes in various scenarios. Observe the ABS system’s reaction to sudden stops, hard braking, and even slight braking during a gentle turn. Discrepancies in the ABS system’s responses can indicate faulty wiring, a damaged sensor, or a problematic module. Consistent and expected responses are the key to confirming a successful replacement.

Common Installation Errors and Rectification

Mistakes are part of the process, but understanding their causes is critical to avoiding repetition. Incorrectly seated wiring harnesses can lead to intermittent errors, while an improperly secured module can result in instability and reduced braking performance. Carefully double-checking all connections and adhering to the manufacturer’s torque specifications are essential steps to ensure the longevity and reliability of the replacement.

Troubleshooting Table

| Potential Issue | Possible Cause | Solution |

|---|---|---|

| ABS warning light illuminated | Faulty wiring, module malfunction, sensor issues | Check wiring connections, test the module’s functionality, inspect sensors |

| ABS system fails to activate during braking | Module malfunction, sensor failure, damaged wiring | Replace the module, inspect wiring, replace sensors |

| ABS system activates erratically | Damaged wiring, module malfunction, intermittent short circuit | Inspect and repair wiring, replace the module, check for short circuits |

| Noises from the ABS system during operation | Faulty pump, damaged hydraulic components, worn brake pads | Check the pump, inspect hydraulic lines, replace worn brake pads |

Testing the ABS Module’s Functionality

A crucial step after installation is to test the ABS module’s functionality. Drive the vehicle under various conditions, including hard braking, cornering, and sudden stops. Monitor the ABS warning light for any indications of errors. If the system operates without any unusual behaviour or warning lights, the replacement is successful. Pay particular attention to the responsiveness and precision of the braking system in each scenario.

This should reveal any subtle malfunctions that could have been missed during initial inspection.

Post-Replacement Checks

A hush fell over the workshop as the spectral glow of the replaced ABS module illuminated the intricate mechanisms. A silent promise hung in the air – a promise of restored braking prowess. But the work wasn’t over. The journey to true functionality lay in a series of meticulous checks, each step a whispered incantation to ensure the vehicle’s silent guardian was now truly awake.The replacement of the ABS module is not merely a mechanical act; it’s a delicate dance with the vehicle’s electronic nervous system.

A single misplaced connection or a faulty setting could lead to a cascade of problems, rendering the entire system unresponsive, or even worse, potentially dangerous. Thorough post-replacement checks are crucial for restoring the vehicle’s braking capabilities and confirming the module’s successful integration.

Road Test Verification

A road test is not just a drive; it’s a rigorous examination of the vehicle’s responsiveness and the ABS module’s performance under various conditions. This dynamic evaluation provides valuable insights into the module’s integration into the vehicle’s system, revealing any subtle malfunctions that might otherwise remain hidden. The test should cover a range of speeds and braking scenarios, including light braking, hard braking, and emergency stops.

ABS Module Functionality Checklist

This checklist ensures all critical aspects of the ABS module’s operation are validated after installation. A well-executed check minimizes the risk of unforeseen problems and ensures the safety of the vehicle’s occupants.

- Braking Response: Assess the responsiveness of the braking system under varying conditions, from gentle braking to emergency stops. Feel for any unusual delays or inconsistencies in the braking action. A smooth and predictable response confirms proper ABS module operation.

- ABS Activation: Observe for the characteristic pulsing sensation during hard braking. This pulsating action is the ABS system’s signature, confirming its activation. The absence of this pulsing, or an erratic pulsing pattern, warrants further investigation.

- Warning Lights: Inspect the dashboard for any warning lights related to the ABS system. A steady glow or blinking patterns could signal a problem. Any such lights should be addressed immediately by a qualified technician.

- Steering Stability: During braking maneuvers, ensure the vehicle maintains a stable and controlled trajectory. Any unusual pulling or veering indicates potential issues with the ABS module or other associated components.

Ensuring Vehicle Safety

The post-replacement checks aren’t just about functionality; they’re about safeguarding the passengers. These rigorous steps confirm the ABS module’s reliability and the safety of the vehicle.

- Manufacturer Specifications: Adherence to manufacturer’s specifications is paramount. Consult the vehicle’s repair manual for specific guidelines and procedures related to the ABS module replacement and post-installation checks. These instructions are tailored to the specific vehicle model and will help ensure the safety of the vehicle.

- Professional Inspection: A qualified technician should conduct a thorough inspection of the entire braking system after the ABS module replacement. Their expertise ensures all aspects of the system function correctly and are properly integrated.

Important Considerations

Failure to properly perform post-replacement checks can lead to serious consequences. Imagine a scenario where a driver is caught in a sudden emergency situation and the ABS system malfunctions. The result could be catastrophic. Thus, careful attention to these steps is essential to ensure the vehicle is safe for operation.

Safety Precautions

A whisper of the unseen, a phantom’s touch. The world of automotive mechanics, especially when dealing with the intricate heart of the braking system, holds a certain mystique. It’s a dance with danger, a delicate balance between precision and peril. Before delving into the labyrinth of the ABS module replacement, one must acknowledge the potential hazards and understand the safety protocols to ensure a successful and, crucially, safe endeavor.This section unveils the crucial precautions necessary to navigate the intricate dance between the mechanics and the hidden forces of the vehicle’s braking system.

Proper safety measures are not merely suggestions; they are essential components of the procedure.

Electrical Safety Measures

Electrical systems within a vehicle often hide a surprising power, lurking beneath the surface of the dashboard. A mishandled wire or a misplaced connection can ignite a silent inferno, or worse, lead to electric shock. Proper electrical safety measures are paramount.

- Always disconnect the vehicle’s battery terminals before commencing any work involving electrical components. This is crucial to prevent accidental short circuits and electrical shocks. Failure to do so can lead to unforeseen consequences, ranging from minor discomfort to potentially fatal shocks.

- Use insulated tools and gloves to prevent electrical shocks. These are not mere accessories; they are your first line of defense against electrical mishaps. The potential for harm is real, and the consequences of a mistake can be dire.

- Ensure all tools are in good working order and free from any visible damage. A faulty tool can introduce unexpected risks and compromise the safety of the entire operation. This is not merely a matter of convenience; it is a crucial safety protocol.

Environmental Considerations, How to replace abs module

The workshop, or even a driveway, can become a battlefield of potential hazards if not treated with respect. A well-ventilated area is paramount.

- Work in a well-ventilated area to prevent the inhalation of fumes or the buildup of harmful gases. Ignoring this precaution can lead to serious health issues, from mild discomfort to long-term respiratory problems. The workshop environment can become a hidden threat if proper ventilation is not maintained.

Physical Safety Measures

The mechanics of vehicle repair often involve handling delicate parts and potential moving components.

- Always wear appropriate safety gear, including safety glasses, gloves, and closed-toe shoes. These precautions safeguard against flying debris, sharp edges, or accidental contact with potentially hazardous materials. Neglecting these safety precautions can lead to injuries, ranging from minor cuts to more serious lacerations.

- Follow proper lifting techniques when handling heavy components. Improper lifting techniques can lead to back injuries, which can significantly impact one’s health and well-being. The weight of components can often be underestimated, and improper lifting techniques can lead to serious back injuries.

- Ensure the work area is free from obstructions and hazards. This precaution prevents accidents, which could result in injuries or damage to the vehicle. A cluttered or unorganized workspace can be a silent invitation to disaster.

Mitigation Procedures

Accidents can happen, even with the best precautions in place. Developing strategies to mitigate potential hazards is crucial.

- Have a first-aid kit readily available and know how to use it. This is not merely a formality; it is a practical measure that can mitigate the impact of potential injuries.

- Inform someone of your work schedule and location. This provides a crucial safety net in case of unforeseen circumstances. This is not just a social courtesy; it’s a critical safety measure.

- Always double-check your work before proceeding. This is not a sign of excessive caution; it is a fundamental safety measure. This approach ensures accuracy and minimizes potential errors.

Common Mistakes and How to Avoid Them

The path to a successful ABS module replacement is fraught with subtle pitfalls, like shadows in a darkened workshop. One misstep, one careless connection, and the system, once a marvel of automotive engineering, becomes a cryptic enigma, whispering secrets only a seasoned technician can decipher. Avoiding these common mistakes is crucial for a smooth and reliable repair.The shadowy realm of automotive repair often hides common pitfalls.

Misinterpreting intricate wiring diagrams, misplacing crucial components, or neglecting seemingly insignificant details can lead to frustratingly complex issues. Understanding the potential traps and developing preventative measures is key to successful module replacement.

Identifying Common Errors

Incorrect installation procedures are a significant source of problems after ABS module replacement. These errors can manifest in various ways, ranging from the seemingly innocuous to the critically impactful. Careless handling of sensitive components can introduce subtle damage that may only manifest as erratic behavior down the line.

- Incorrect Wiring Connections: A seemingly minor miswiring can render the entire system inoperable. A simple reversal of positive and negative terminals can lead to permanent damage to the module or related components. Double-check all connections against the manufacturer’s wiring diagram before finalizing any connections.

- Improper Component Handling: ABS modules are delicate electronic devices. Rough handling, exposure to moisture, or dropping during removal or installation can cause internal damage. Carefully handle the module and ensure it is never exposed to extreme temperatures or humidity.

- Omission of Grounding Connections: Neglecting grounding connections can lead to erratic behavior, causing the system to malfunction unpredictably. Ensure every component has a secure ground connection. This is crucial for stable operation and to prevent unexpected electrical surges.

- Inadequate Torque on Mounting Screws: Loose mounting screws can lead to vibrations and instability within the system, potentially causing malfunctions. Use a torque wrench to ensure the screws are tightened to the manufacturer’s specifications. This prevents unwanted movement and ensures the ABS module is securely mounted.

- Ignoring the Module’s Orientation: Some modules have specific orientations for proper functionality. Ignoring this can lead to incorrect operation or system failure. Always follow the manufacturer’s guidelines for module orientation to prevent potential issues.

Consequences of Incorrect Installation

The effects of incorrect installation procedures can range from minor inconveniences to significant system failures. A subtle misalignment in the ABS module, for example, can cause intermittent braking issues, while a faulty wiring connection could lead to complete system failure. The consequences often manifest as a confusing array of symptoms, making diagnosis challenging.

- Erratic Braking Performance: Incorrect wiring or module orientation can result in unpredictable braking responses. The vehicle might exhibit jerky or inconsistent braking behavior, a warning sign of underlying problems.

- ABS Malfunction Indicators: The ABS warning light might illuminate intermittently or constantly, indicating a deeper issue within the system. This can be a symptom of mismatched or damaged components.

- Reduced Vehicle Stability: A malfunctioning ABS system can impact vehicle stability, potentially leading to dangerous situations during driving. The system’s role in maintaining stability during braking becomes compromised.

- Permanent Component Damage: Severe errors in installation can permanently damage the ABS module or other components. This leads to significant repair costs and extended downtime.

Importance of Accurate Wiring and Component Connections

Accurate wiring and component connections are fundamental to the proper functioning of the ABS system. Any deviation from the manufacturer’s specifications can lead to unpredictable results, even a subtle misalignment. A thorough understanding of the system’s architecture and careful adherence to the diagrams are essential.

- Verification Procedures: Carefully verify each connection against the manufacturer’s wiring diagram. This step is crucial for ensuring accuracy and preventing errors. Use diagrams to match color-coded wires to the appropriate terminals.

- Component Compatibility: Ensure all components used during the replacement are compatible with the vehicle’s specifications. Using incompatible parts can cause malfunctions and system failure.

- Thorough Testing: After the installation, conduct thorough testing to identify any issues. This step ensures the system is functioning correctly and that no problems are present.

Preventing Damage to the ABS Module

Handling the ABS module with care is critical to avoid any damage during removal or installation. A simple drop or exposure to moisture can lead to internal component damage, rendering the module unusable. Respect the delicate nature of the electronic components.

- Proper Support: Use appropriate tools to support the module during removal and installation, minimizing the risk of dropping or damaging it. A secure mounting area prevents unexpected movement and damage.

- Protective Measures: Use protective coverings to shield the module from moisture and other environmental hazards. Protecting the module from dust, debris, and chemicals prevents damage.

- Careful Removal and Installation: Follow the steps carefully, and proceed slowly to prevent damage to the module. Each step should be methodical and well-executed to ensure the integrity of the component.

Summary

In conclusion, replacing an ABS module, while potentially daunting, is a manageable task with the right knowledge and preparation. Following this guide, you’ll gain a comprehensive understanding of the process, from identifying the module to performing post-replacement checks. By prioritizing safety precautions and diligently following the steps Artikeld, you can ensure a successful and safe replacement, restoring your vehicle’s vital braking system to optimal performance.

Remember, if you are uncomfortable with any step, seek professional assistance.

Detailed FAQs: How To Replace Abs Module

Q: What are the common signs of an ABS module malfunction?

A: Common signs include brake warning lights on the dashboard, pulsating brakes, a lack of ABS functionality during braking, and unusual noises from the braking system.

Q: What special tools are needed for ABS module replacement?

A: Essential tools often include a torque wrench, various screwdrivers, a multimeter, and potentially specialized tools depending on the vehicle model. Safety equipment such as gloves and eye protection are also crucial.

Q: How long does the ABS module replacement typically take?

A: The time required for replacing an ABS module can vary greatly based on vehicle make and model, and your skill level. Expect a time range from several hours to a full day.

Q: What are some common mistakes to avoid during the process?

A: Common mistakes include improper wire connections, neglecting safety precautions, and rushing through the steps. Accurate wiring and careful component handling are essential.