How long to let oil drain? This is a critical question for any mechanic or DIY enthusiast. Understanding the factors influencing drain time, from oil type to vehicle type, is key to efficient and safe oil changes. This guide delves into the nuances of oil drainage, offering practical advice and detailed procedures for various applications. From cars to motorcycles, and even hydraulic systems, we’ll equip you with the knowledge to ensure a smooth and successful oil change, every time.

Various factors significantly impact how long it takes for oil to drain completely. The viscosity of the oil, the vehicle’s design, and even the positioning of the vehicle during the draining process all play a role. This guide meticulously explores these elements, offering a comprehensive understanding of the drain time for different oil types and vehicle types. Learn how to effectively drain oil from various types of equipment and machinery, and how to prevent common issues like slow drainage or leaks.

Understanding Drain Times: How Long To Let Oil Drain

Oil drain times are crucial for efficient maintenance and environmental responsibility. Properly timed drain procedures prevent potential engine damage, ensure optimal lubricant performance, and minimize environmental impact from discarded oil. Accurate estimations are critical for scheduling maintenance tasks effectively.Understanding the factors affecting drain times allows for better informed decisions about maintenance schedules. This includes recognizing the interplay of oil type, vehicle type, viscosity, gravity, and positioning.

Detailed knowledge of these factors enables mechanics and vehicle owners to optimize oil changes, reducing unnecessary costs and potential issues.

Factors Influencing Oil Drain Times

Various factors influence the time it takes for oil to drain completely. Understanding these factors is key to proper maintenance procedures.

- Oil Type:

- Oil Viscosity:

- Gravity and Positioning:

- Vehicle Type:

Different types of oil, including motor oil, hydraulic oil, and transmission fluid, have varying viscosities and densities. These properties directly affect the rate at which the oil drains. For instance, thinner oils, like those used in some high-performance applications, will drain more quickly than thicker oils used in heavy-duty vehicles.

Oil viscosity, a measure of its resistance to flow, plays a significant role. Thicker oils, often used in extreme temperatures or high-stress applications, drain more slowly than thinner oils. The viscosity index is often specified by manufacturers. For example, a 10W-30 motor oil, common in many passenger cars, will drain more quickly than a 50W-50 oil used in older trucks or motorcycles operating in extremely hot conditions.

Gravity significantly impacts the draining process. The slope of the oil pan and the vehicle’s position directly influence the rate of drainage. Positioning the vehicle on a slight incline, with the oil pan angled downwards, facilitates faster drainage. Similarly, the angle of the vehicle’s engine relative to the ground can affect how quickly oil drains from the engine.

Different vehicle types, such as cars, trucks, and motorcycles, have varying oil pan sizes and drain plug configurations. Cars typically have smaller oil pans and quicker drain times compared to larger vehicles like trucks. Motorcycle oil pans are generally smaller and have faster drain times, though the specifics vary greatly based on the motorcycle’s make and model.

Comparative Analysis of Drain Times

This table illustrates the estimated drain times for various oil types in different vehicle types. These are approximate values and can vary based on specific vehicle models and conditions.

| Vehicle Type | Oil Type | Estimated Drain Time (minutes) |

|---|---|---|

| Passenger Car | 10W-30 Motor Oil | 5-10 |

| Passenger Car | 15W-40 Motor Oil | 7-12 |

| Light Truck | 15W-40 Motor Oil | 10-15 |

| Heavy-Duty Truck | 20W-50 Motor Oil | 15-20 |

| Motorcycle | Motorcycle-Specific Oil | 3-7 |

| Hydraulic System | Hydraulic Fluid | 10-30 (varies greatly based on system) |

Methods for Draining Oil

Proper oil drainage is crucial for maintaining optimal engine performance and extending the lifespan of various equipment. Improper procedures can lead to significant damage, ranging from component wear to environmental pollution. This section details the steps and considerations for safely and effectively draining oil from a variety of systems.Effective oil drainage methods prioritize safety, environmental responsibility, and the preservation of equipment.

Carefully following procedures minimizes the risk of spills, injuries, and potential damage to the equipment or surrounding environment. Different equipment types necessitate tailored approaches.

Draining Oil from a Car Engine

Engine oil drainage is a critical maintenance task. The procedure typically involves several steps. First, position the vehicle on a level surface and engage the parking brake. Next, locate the oil drain plug, often located on the bottom of the engine. Using a suitable drain pan, place it beneath the plug.

Carefully loosen and remove the drain plug. Allow the oil to drain completely, typically for 15-20 minutes. Once the oil flow ceases, reinstall the drain plug, tightening it securely. Finally, check for leaks.

Draining Oil from Different Types of Equipment

Various equipment types require specific draining procedures. Agricultural machinery, construction equipment, and industrial machinery often feature different oil pan configurations and drain plug locations. The operator should consult the manufacturer’s manual for precise instructions.

Draining Oil from a Motorcycle

Motorcycle oil changes are similar to car engine oil changes, though often involve slightly different steps. Ensure the motorcycle is on a level surface and the parking brake is engaged. Locate the oil drain plug and place the appropriate drain pan beneath it. Loosen and remove the drain plug, allowing the oil to drain completely. Reinstall the plug and tighten it securely.

Always check for leaks after completing the process.

Comparing and Contrasting Drain Pan Types

Different drain pan types suit various applications. Metal pans are durable and resistant to most fluids, but they may not be the best choice for sensitive surfaces. Plastic pans are lightweight and often more affordable, but may not be as durable as metal pans. Reusable pans are environmentally friendly and cost-effective in the long run. The choice depends on the volume of oil to be drained, the desired level of durability, and environmental considerations.

Table of Procedures for Draining Oil from Various Vehicle Types

| Vehicle Type | Location of Drain Plug | Drain Pan Type | Estimated Drain Time |

|---|---|---|---|

| Car | Typically on the bottom of the engine | Metal or Plastic | 15-20 minutes |

| Motorcycle | Usually located under the engine | Metal or Plastic | 10-15 minutes |

| Truck | Typically located on the bottom of the engine | Large Metal | 20-30 minutes |

| Small Equipment | Refer to manual | Metal or Plastic | 5-10 minutes |

Draining Oil from a Hydraulic System

Hydraulic systems often require specialized procedures for draining oil. The first step involves identifying the drain valve or plug. Next, place a suitable drain pan beneath the valve. Open the valve slowly to allow the oil to drain completely. Once the oil flow ceases, close the valve.

After ensuring no oil remains in the system, check for leaks and clean up any spills.

Tools and Equipment for Draining Oil

Proper oil draining necessitates careful selection and use of appropriate tools and equipment. Safety and efficiency are paramount in this process, as improper handling can lead to spills, injuries, and environmental damage. Choosing the right tools ensures a smooth and controlled drain, minimizing the risk of accidents and maximizing the outcome.

Essential Tools for Safe Draining

Essential tools for safe oil draining include a suitable drain pan or container, a wrench appropriate for the drain plug size, and protective gear like gloves and safety glasses. The choice of each tool directly impacts the success and safety of the procedure. Proper selection minimizes the risk of spills, injury, and environmental contamination.

- Drain Pan/Container: A sturdy, leak-proof container is crucial for collecting the drained oil. The container’s capacity should be sufficient to hold the entire volume of oil being drained. Material selection should prioritize durability and resistance to oil leakage. Examples include metal pans, plastic containers with lids, and specialized oil collection containers. Choosing a container that is the right size and is resistant to leaks is paramount.

- Wrench: A suitable wrench is essential for loosening and tightening the drain plug. Using a wrench that is too small or too large can damage the plug or the drain point. The size of the wrench must precisely match the drain plug’s dimensions to prevent damage. This prevents accidental damage to the vehicle’s oil system.

- Gloves and Safety Glasses: Protective gear is vital for preventing contact with potentially harmful substances. Gloves protect hands from oil spills, while safety glasses safeguard eyes from flying debris or splashes. These are essential to maintain personal safety throughout the procedure.

Drain Plugs and Their Importance

Drain plugs are crucial components of the vehicle’s oil system. They are designed to seal the oil pan and prevent oil leakage. The type of drain plug varies depending on the vehicle’s make and model. Different types of drain plugs have different characteristics, requiring specific tools for their removal and replacement.

- Standard Drain Plugs: These plugs typically use a standard hex or square shape and require a corresponding wrench for removal and installation. The proper use of the correct wrench prevents damage to the plug or the oil pan.

- Magnetic Drain Plugs: These plugs incorporate a magnetic surface that captures metal particles from the oil. This feature aids in maintaining the cleanliness of the oil pan and can prevent potential damage to the engine. Regularly checking and replacing these plugs is recommended.

Oil Filters in the Draining Process

Oil filters play a vital role in the oil draining process by separating impurities and contaminants from the oil. Proper oil filtration ensures that the engine receives clean oil, improving its performance and lifespan. Different filter types exist, each with specific functions and applications.

- Cartridge Filters: These filters are commonly used in automobiles and consist of a cartridge that is replaced during oil changes. They are often disposable and require careful disposal to prevent contamination. The correct replacement of these filters is critical.

- Spin-on Filters: These filters are commonly used in automotive engines. They are attached to the engine oil system and are crucial in maintaining the engine’s performance. The use of appropriate filter types is important.

Oil Container Types for Collection

Different oil container types cater to various needs and applications. The chosen container must be appropriate for the volume of oil being drained and resistant to leaks or spills. Container selection is crucial for environmental protection and safe disposal.

- Metal Pans: Metal pans are durable and can withstand high temperatures, but they may be more difficult to clean. Their strength is essential for larger quantities of oil.

- Plastic Containers: Plastic containers are lightweight and often come with lids, which aids in containment and safety. They are widely used due to their affordability and convenience.

- Specialized Oil Collection Containers: These containers are designed for collecting used oil and are often equipped with features like leak-proof seals and handles. These specialized containers are the best choice for safety and environmental considerations.

Safety Precautions During Draining

Safety is paramount during any oil draining procedure. Following safety guidelines helps prevent injuries and environmental damage. Care must be taken during each stage of the procedure.

- Wear Protective Gear: Always wear appropriate gloves and safety glasses to protect yourself from oil spills and potential hazards. This is the first and most important precaution.

- Work in a Well-Ventilated Area: Ensure the area where you are working is well-ventilated to prevent exposure to harmful fumes. This helps prevent health issues.

- Proper Disposal of Used Oil: Used oil should be disposed of properly to prevent environmental contamination. Following local regulations and guidelines is essential.

Tools and Equipment Needed for Various Oil Types

| Oil Type | Drain Pan | Wrench | Gloves | Safety Glasses | Other Equipment |

|---|---|---|---|---|---|

| Motor Oil | Metal or plastic container | Appropriate wrench size | Oil-resistant gloves | Safety glasses | Oil filter wrench, filter |

| Hydraulic Oil | Specialized hydraulic oil container | Hydraulic wrench | Heavy-duty gloves | Safety glasses | Protective apron, spill kit |

| Transmission Oil | Plastic container with lid | Transmission drain plug wrench | Oil-resistant gloves | Safety glasses | Torque wrench (if applicable) |

Safety Considerations

Properly draining engine oil is crucial, but safety must be paramount. Neglecting safety precautions can lead to severe injuries and environmental damage. This section Artikels the critical safety measures for safe oil draining procedures.Draining engine oil, while seemingly straightforward, presents several potential hazards. These range from the inherent risks of working with hot, potentially contaminated fluids to the environmental implications of improper disposal.

Understanding these risks and implementing the correct safety procedures is essential to minimize harm and protect the environment.

Potential Hazards Associated with Draining Oil

The process involves handling potentially hazardous materials. Hot oil can cause severe burns, and oil spills can contaminate the environment. Used oil itself contains various contaminants, including heavy metals and other potentially harmful substances, posing risks to both human health and the environment. Improper handling can also lead to slips and falls, further compounding the risks.

Importance of Safety Gear During the Oil-Draining Process

Safety gear is essential for minimizing risks. Protective equipment such as heat-resistant gloves, safety glasses, and a long-sleeved shirt are crucial for preventing burns and protecting skin from oil contamination. A sturdy pair of work boots is important for preventing slips and falls, especially on potentially oily surfaces. A respirator, particularly for enclosed spaces, may be necessary to protect against airborne contaminants or fumes.

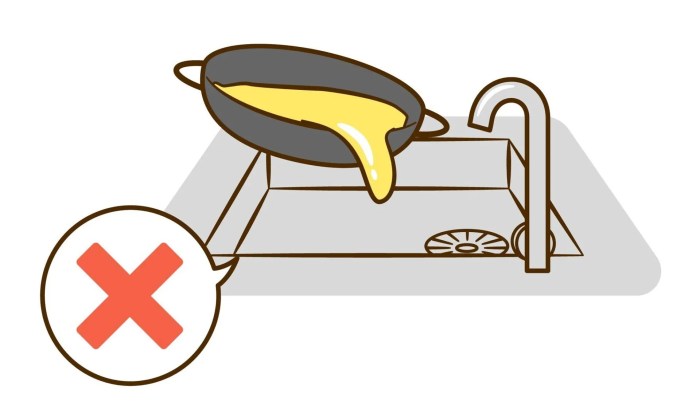

Proper Disposal Methods for Used Oil, How long to let oil drain

Used engine oil should never be disposed of down the drain or in landfills. This practice contaminates water sources and the environment. Proper disposal methods involve taking the oil to a designated recycling center or a facility specializing in hazardous waste disposal. These facilities are equipped to handle used oil safely and responsibly, ensuring its proper recycling or disposal.

Environmental Impact of Improper Oil Disposal

Improper disposal of used engine oil has severe environmental consequences. Oil contamination can harm aquatic life and ecosystems. It can seep into the soil, contaminating groundwater and potentially affecting human health. Furthermore, improper disposal often leads to the release of harmful pollutants into the atmosphere.

Handling Oil Spills

In the event of an oil spill, immediate action is crucial. Contain the spill using absorbent materials like sand or specialized oil-absorbing pads. Avoid spreading the spill further. Contact the appropriate authorities, such as environmental agencies or hazardous material response teams, for guidance and instructions on the cleanup process.

Preventing Oil Leaks During the Draining Process

Careful handling of equipment is vital to prevent leaks. Ensure the oil drain pan is properly positioned and securely placed beneath the drain plug to catch all the draining oil. Using a funnel or other suitable tools can also minimize spills during the pouring process. Inspecting the drain plug and any associated hoses for damage or leaks is essential.

Safety Guidelines for Draining Oil from Different Equipment

- Cars and Light Trucks: Always warm up the engine before draining to allow the oil to flow more easily. Use a drain pan large enough to hold all the oil. Never overfill the drain pan to avoid overflow.

- Heavy Equipment: Consult the equipment’s manufacturer’s manual for specific instructions on oil draining procedures. Ensure all safety mechanisms are engaged, and only trained personnel should perform the task. Use specialized equipment and tools for handling large volumes of oil.

- Industrial Machinery: Consult with a qualified technician for proper procedures. Proper safety protocols and specialized equipment for large-scale oil draining are required to prevent potential hazards.

Troubleshooting Common Issues

Proper oil drainage is crucial for vehicle maintenance, but unforeseen issues can arise. Understanding potential problems and their solutions allows for efficient and safe procedures. Addressing these problems proactively minimizes potential damage to the vehicle and ensures optimal engine performance.

Slow Drainage

Slow drainage can stem from several factors. A restricted drain plug or a partially clogged drain line can impede the flow of oil. Additionally, the viscosity of the oil itself, especially in cold temperatures, can contribute to slower drainage. The use of a funnel, strategically positioned to allow gravity to assist the draining process, can prove helpful.

Furthermore, ensuring the vehicle is positioned on a level surface, facilitating proper drainage, is essential.

Leaks During Drainage

Identifying leaks during the oil-draining process is critical. Leaks may manifest as oil seeping from the drain plug, the oil pan, or other components. A visual inspection is vital. The presence of oil around the drain plug or pan, or even beneath the vehicle, indicates a potential leak. Carefully examine the area around the drain plug and the oil pan, looking for any signs of oil pooling.

If leaks are detected, stop the draining process immediately and contact a qualified mechanic to address the issue. Leaking oil can cause environmental damage and engine malfunction.

Clogged Drain Lines or Filters

Clogged drain lines or filters can impede the flow of oil, resulting in slow drainage. A visual inspection of the drain line and filter for any obstructions is necessary. A buildup of debris or contaminants in the drain line can lead to a restriction. If a clog is suspected, the line should be inspected for any foreign materials or blockages.

Using a suitable cleaning tool to dislodge any obstructions is also advisable. The use of specialized cleaning solutions, if necessary, can help remove the buildup, though this should be done with caution and adhering to the specific instructions provided by the manufacturer.

Oil-Related Issues After Draining

Addressing oil-related issues after draining involves thorough post-drainage checks. This includes inspecting the oil pan for any remaining oil residue and ensuring the drain plug is properly tightened. Improper tightening can lead to leaks. Furthermore, a visual check of the surrounding area, especially beneath the vehicle, should be conducted to confirm no oil remains. A potential cause for a leak can be a damaged or worn-out gasket.

This is important to prevent environmental pollution and potential damage to the vehicle.

Examples of Oil-Related Problems in Different Vehicles

Different vehicle types can experience specific oil-related problems during the draining process. Older vehicles may exhibit more frequent clogging of drain lines due to accumulated debris. High-performance vehicles, with their specialized oil systems, might encounter challenges with maintaining proper oil flow rates. Conversely, vehicles with newer oil systems and filters might experience less clogging but can have complications if oil viscosity is not factored into the draining procedure.

For instance, draining oil from a truck may require longer drain times than a car due to the volume of oil.

Visual Aids and Illustrations

Visual aids play a crucial role in understanding and safely performing automotive oil changes. Clear, concise diagrams and infographics simplify complex procedures, reducing the risk of errors and promoting best practices. These visual representations allow for a more intuitive comprehension of the steps involved, fostering a deeper understanding of the entire process.Visual aids are invaluable tools for both novice and experienced mechanics.

They act as a readily accessible guide, reinforcing correct techniques and highlighting potential pitfalls. By employing a variety of visual formats, from infographics to detailed diagrams, a comprehensive understanding of oil change procedures is facilitated.

Engine Oil Drain Process Infographic

This infographic should present the steps in a clear, sequential manner, using icons and concise text. It should begin with the vehicle parked on a level surface, showcasing the location of the drain plug and the necessary tools. Subsequent steps should depict loosening the drain plug, positioning the oil pan, and finally tightening the drain plug. The infographic should emphasize safety precautions, such as wearing gloves and eye protection.

A final step should illustrate the proper disposal of used oil.

Oil Flow Diagram

A diagram illustrating the oil flow during the draining process is essential. The diagram should start with the engine’s oil reservoir and trace the oil’s path through the engine’s various components. It should clearly show the oil’s descent into the drain plug, highlighting the crucial role of gravity in the process. The diagram should include labels for key components and arrows to indicate the direction of oil flow.

This will provide a visual representation of the oil’s journey from the engine to the collection pan.

Drain Plug Types

- Different types of drain plugs are available, each designed for specific vehicle applications. These include standard hex-head plugs, and potentially specialized plugs for various engine types. The infographic should illustrate the differences in design and the appropriate tools needed for each type.

- The infographic should include detailed information about the specifications of each plug, including size, material, and torque requirements. This will help mechanics select the right plug for their task.

- Different types of drain plugs (e.g., standard hex-head, specialized plugs for certain engine types) will be displayed with corresponding images. Each image should be labeled with the specific type of drain plug and its intended application. This visual representation aids in recognizing and understanding the various plug types.

Used Oil Disposal Illustration

This illustration should clearly depict the proper methods for used oil disposal. It should show the use of designated containers for used oil, and the importance of adhering to local regulations. The image should highlight the environmental hazards associated with improper disposal and the importance of environmentally sound practices. The illustration should clearly show how to safely dispose of used oil, emphasizing the need for recycling or designated disposal points.

Safety Equipment Illustration

This illustration should depict the essential safety equipment required during an oil change. It should include images of safety glasses, work gloves, and appropriate protective clothing, clearly indicating the purpose of each item. The illustration should stress the significance of personal protective equipment (PPE) in minimizing risks and hazards. This illustration should visually depict how to safely handle tools and fluids, highlighting the need for personal protective equipment.

Properly Equipped Oil-Changing Station

A visual representation of a properly equipped oil-changing station should depict a well-organized workspace. The image should showcase the location of essential tools, such as oil pans, drain plugs, wrenches, and safety equipment. This visual aid should highlight the importance of a clean and well-organized workspace for efficient and safe oil changes. The picture should display the station with all necessary equipment, including oil filters, lubricants, and tools, arranged systematically to promote safety and efficiency.

It should emphasize the importance of proper organization and labeling for quick access to tools and materials.

End of Discussion

In conclusion, efficient and safe oil draining hinges on understanding the interplay of various factors. This guide provides a practical framework for determining the optimal drain time, considering oil type, vehicle specifications, and positioning. By following the detailed procedures and safety guidelines, you can effectively drain oil from various equipment while minimizing risks and maximizing efficiency. Remember, proper oil disposal is crucial for environmental sustainability.

Let this guide be your reliable companion in mastering the art of oil draining.

Essential FAQs

How do I prevent oil leaks during the draining process?

Ensuring the drain plug is tightened securely and checking for any damaged or loose connections in the oil system are crucial steps. Properly securing the drain pan and positioning the vehicle for gravity drainage also contribute to leak prevention.

What safety precautions should I take when draining oil?

Always wear appropriate safety gear, such as gloves and eye protection. Ensure the work area is well-ventilated and that proper disposal methods are followed. Carefully handle the used oil and follow the local regulations for disposal.

What are the common problems encountered during oil draining?

Slow drainage, leaks, clogged drain lines, or issues with the oil filter are some common problems. Careful inspection and troubleshooting are vital to resolve these issues quickly and effectively.

What are the different types of oil containers used for oil collection?

Different types of oil containers are available, including metal pans, plastic containers, and specialized oil catchers. The selection depends on the volume of oil to be collected and the specific application.