How to tell when beef jerky is done is crucial for any jerky enthusiast. This guide dives deep into the science and art of achieving that perfect, chewy bite, avoiding both the mushy and the brittle extremes. We’ll explore visual cues, thermometer techniques, and sensory evaluations, plus how drying time and recipe specifics affect the outcome.

From pale and translucent to a deep, rich hue, we’ll break down the color changes that signal doneness. Learn how to use a meat thermometer for precise internal temperatures and the crucial role of texture and smell in judging perfection. We’ll cover different jerky types and cooking methods to help you master your jerky game.

Identifying Doneness

Beef jerky, a beloved snack, requires careful attention to ensure it’s cooked to perfection. Overcooked jerky becomes dry and brittle, while undercooked jerky can retain a raw, potentially unsafe, quality. Mastering the art of doneness involves understanding the visual cues, color changes, and textural shifts during the cooking process. Knowing when to pull the jerky from the heat is critical to achieving the ideal, savory, and satisfying experience.

Visual Inspection for Doneness

Proper visual inspection is key to achieving perfectly cooked jerky. Examine the jerky’s surface for changes in color and texture. Look for a consistent color throughout the jerky, and feel for a slight firmness, but not hardness. This will give you a better understanding of the jerky’s readiness.

Color Changes During Cooking

The color of beef jerky significantly changes as it cooks. Initially, the jerky might appear pale and slightly translucent, indicative of undercooking. As the cooking process continues, the jerky’s color deepens, becoming richer and more opaque. The exact shade depends on the ingredients and the specific recipe. A deep, rich color signals that the jerky is likely perfectly cooked.

However, prolonged cooking can lead to a dry, darkened color, signifying overcooking.

Doneness Comparison Table

| Stage | Color | Texture | Smell |

|---|---|---|---|

| Undercooked | Pale, slightly translucent | Moist, pliable | Slightly raw, potentially slightly sweet |

| Perfectly Cooked | Deep, rich color (depending on recipe) | Slightly firm, chewy, but pliable | Distinctly cooked aroma, characteristic of jerky |

| Overcooked | Dry, darkened color | Hard, brittle | Strong, slightly burnt aroma |

Jerky Types and Doneness Colors

Different jerky types will exhibit varying shades of doneness. The color of the finished product will depend on the ingredients and the specific preparation method. Here’s a table outlining the typical doneness colors for various jerky types:

| Jerky Type | Typical Doneness Color |

|---|---|

| Beef Jerky (Standard) | Deep reddish-brown to dark brown |

| Spicy Beef Jerky | Deep reddish-brown to dark brown, with possible hints of red from spices |

| Teriyaki Beef Jerky | Deep reddish-brown to mahogany brown, with a possible glaze sheen |

| Pork Jerky | Deep reddish-brown to light brown, depending on the seasoning |

Using a Thermometer

Accurately determining the doneness of beef jerky requires precise temperature readings. A meat thermometer provides a reliable method to ensure the jerky is cooked through and safe to eat. This method eliminates the guesswork associated with visual or tactile assessments, guaranteeing consistent results and preventing potential foodborne illnesses.Using a thermometer offers a straightforward way to gauge the internal temperature of the jerky, providing a definitive measure of doneness.

Understanding the relationship between temperature and bacterial inactivation is crucial for food safety. Different jerky types will have varying safe internal temperatures based on their ingredients and desired level of doneness.

Safe Internal Temperatures for Jerky

Safe internal temperatures for jerky vary depending on the specific ingredients and desired level of doneness. A general guideline is to aim for an internal temperature that effectively eliminates harmful bacteria, while maintaining the desired texture and flavor.

- For most beef jerky types, a safe internal temperature range is between 160°F (71°C) and 170°F (77°C). This range effectively deactivates harmful bacteria and ensures the jerky is safe to consume.

- For jerky containing added ingredients or spices, such as garlic or chili powder, the safe internal temperature range might be slightly higher to account for potential differences in bacterial load or other food safety considerations.

- When using a thermometer to check the internal temperature, it’s essential to place the probe into the thickest part of the jerky. This ensures an accurate reading that reflects the overall temperature of the meat product.

Using a Meat Thermometer

The process involves inserting a meat thermometer into the thickest part of the jerky. Ensure the thermometer’s probe is completely immersed within the meat. Allow sufficient time for the thermometer to register the accurate internal temperature. Avoid taking measurements near the surface, as this may not represent the internal temperature.

- Proper insertion of the thermometer probe is crucial for accurate readings. The probe should be inserted deep enough to ensure contact with the center of the meat.

- Monitor the temperature reading closely. Once the desired temperature is reached, remove the jerky from the smoker or oven.

- Different jerky types will have varying optimal internal temperatures. Always consult specific recipes or guidelines for recommended temperatures for a particular jerky recipe.

Thermometer Types for Jerky

Choosing the right thermometer for checking jerky’s internal temperature is essential for accuracy and efficiency. Different types of thermometers offer varying degrees of convenience and precision.

| Thermometer Type | Pros | Cons |

|---|---|---|

| Instant-read thermometer | Fast, accurate readings, easy to use, inexpensive | Can be slightly less accurate than probes, might not provide continuous monitoring |

| Digital probe thermometer | Accurate, can monitor temperature continuously, suitable for complex cooking processes | More complex setup, may require more space, potentially higher cost |

Sensory Evaluation

Beyond the thermometer, a crucial aspect of determining jerky’s readiness involves sensory evaluation. This approach allows for a nuanced understanding of the desired texture and chewiness, considering personal preferences and the specific flavor profile. Recognizing the subtle shifts in texture and aroma provides a deeper appreciation for the culinary process.The sensory evaluation of jerky goes beyond simply tasting it.

It encompasses the examination of both texture and smell to confirm doneness and achieve the perfect level of crispness, chewiness, or tenderness. This multifaceted approach provides a holistic understanding of the jerky’s quality and its suitability for individual tastes.

Different Ways to Evaluate Texture and Chewiness

Jerky’s texture and chewiness vary significantly depending on the desired outcome. Some individuals prefer a chewy texture, while others favor a more tender, almost melt-in-your-mouth sensation. To determine the optimal texture, try biting into the jerky. A jerky piece should offer a consistent resistance. A jerky piece should not crumble or break apart easily.

Notice how much force is needed to bite through it. This evaluation allows for an accurate assessment of its doneness. The goal is to identify a balance between texture and chewiness.

Identifying Optimal Texture for Various Tastes

Different flavors of jerky often call for specific textures. Spicy jerkies, for instance, frequently benefit from a firm, yet slightly yielding texture, that provides a satisfying contrast to the intense heat. Sweet and savory jerky might be best when it’s more tender and melts in the mouth, allowing the flavors to blend more easily. Consider the flavor profile when deciding on the optimal texture.

A balanced approach to both taste and texture is key to creating a satisfying eating experience.

Importance of Smell as an Indicator of Doneness

The smell of jerky can also offer clues about its doneness. A jerky piece that is fully cooked will usually have a pleasant, savory aroma. A jerky piece that smells off or has an unappealing smell should not be consumed. This aspect is particularly important to identify any signs of undercooking or spoilage. The aroma is a vital indicator of the jerky’s internal condition and a significant part of the sensory evaluation.

Common Jerky Flavors and Their Typical Texture/Doneness Profiles

| Flavor | Typical Texture/Doneness Profile |

|---|---|

| Teriyaki | A slightly chewy, tender texture, allowing the savory flavors to permeate. |

| Spicy Korean | Firm, slightly yielding texture to provide a satisfying contrast to the intense heat. |

| Sweet and Savory | Tender, almost melt-in-your-mouth texture that enhances the blend of sweet and savory flavors. |

| Smoked | A firm, chewy texture, with the distinct smoked flavor complementing the texture. |

| Bourbon | A moderately chewy texture, allowing the bourbon flavor to be appreciated alongside the texture. |

Drying Time Considerations

Beef jerky’s ideal texture and flavor hinge significantly on the meticulous control of its drying process. Understanding the relationship between drying time and doneness is crucial for achieving the desired outcome. The right drying time ensures a palatable chewiness, avoiding either overly tough or overly soft jerky.The drying process directly influences the final texture and flavor profile of the jerky.

Longer drying times typically result in a firmer, crispier texture, while shorter drying times yield a softer, more pliable product. Flavor development is also affected, with longer drying times often leading to a more pronounced, concentrated meat flavor.

Relationship Between Drying Time and Doneness

Drying time is intricately linked to doneness. Properly dried jerky is not only safe to eat but also delivers the optimal balance of moisture, texture, and flavor. This requires careful monitoring of the drying process, ensuring that the internal temperature reaches a safe level while maintaining the desired moisture content. Over-drying leads to jerky that is too tough and chewy.

Factors Influencing Drying Time

Several key factors impact the drying time required for beef jerky. Understanding these factors allows for more precise estimations and control over the process.

- Jerky Thickness: Thicker pieces of jerky take longer to dry than thinner ones. The surface area available for moisture evaporation plays a critical role. A thicker piece will require a longer drying time to reach the same level of doneness as a thinner piece. A common rule of thumb is that thinner jerky requires a shorter drying time.

For example, a 1/4-inch thick piece of jerky might take 24 hours, while a 1/2-inch thick piece might need 48 hours or more to achieve similar doneness. The exact drying time will also depend on other factors like humidity and the type of drying method used.

- Ambient Humidity: Higher humidity levels in the environment slow down the drying process. Moisture in the air competes with the moisture loss from the jerky. A drier environment accelerates the evaporation of moisture, significantly reducing the drying time needed to reach doneness. For example, a home with high humidity might require more time to dry jerky compared to a home with low humidity.

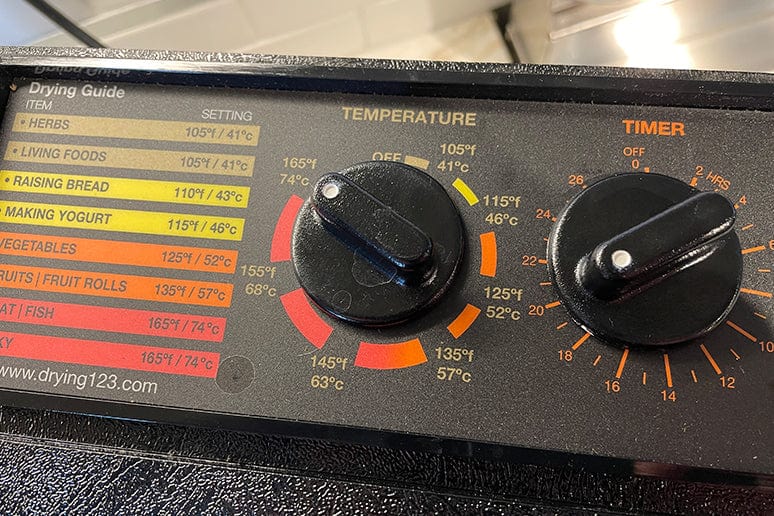

- Drying Method: Different drying methods (e.g., air drying, dehydrators, solar drying) have varying effects on drying time. Dehydrators often provide more consistent and controlled drying, potentially leading to faster drying times compared to air drying in a home environment. Solar drying, depending on the weather conditions, might result in slower drying times. The drying method chosen should be aligned with the desired final product and the available resources.

- Temperature: Higher temperatures accelerate the evaporation of moisture, thus reducing drying time. However, excessively high temperatures can result in jerky that is over-dried and tough. A carefully controlled temperature is essential to maintain the desired texture and flavor.

Estimating Drying Time Based on Jerky Thickness, How to tell when beef jerky is done

A rough estimate for drying time can be made based on the thickness of the jerky. This estimate is dependent on several other factors, and serves as a general guideline.

| Jerky Thickness (inches) | Estimated Drying Time (hours) |

|---|---|

| 1/4 | 24-36 |

| 1/2 | 48-72 |

| 3/4 | 72-96 |

Note: These are estimates and may vary based on environmental factors, the specific drying method, and the initial moisture content of the meat. Constant monitoring and adjustment of the drying process are vital for optimal results.

Recipe Specifics

Crafting the perfect jerky involves more than just timing; understanding the nuances of different recipes is crucial. Varied ingredients and preparation methods influence the ideal doneness point. Each recipe’s unique characteristics demand specific attention to ensure the desired outcome.

Impact of Recipe Variations on Doneness

Different jerky recipes demand different doneness levels. Sweet and spicy varieties, for instance, often require varying degrees of moisture content. Sweet jerky, for example, might need to maintain a slightly higher moisture level for a balanced flavor profile, while spicy jerky might benefit from a slightly drier texture to accentuate the heat.

Doneness Criteria for Different Jerky Types

The desired outcome greatly affects the optimal doneness point. Sweet jerky, with its focus on sugar and molasses, often requires a more moist consistency. The sugar content influences the drying process, and excessive drying can lead to a less palatable sweetness. Spicy jerky, on the other hand, typically demands a drier texture, allowing the spice flavors to be more pronounced.

The heat is enhanced by a crispier texture, while maintaining enough moisture to prevent the spice from becoming overly harsh.

Cooking Method Variations and Their Effect on Doneness

The cooking method significantly impacts the final texture and doneness. Smoking jerky, for instance, imparts a unique smoky flavor, potentially altering the drying time and the ideal moisture level. Oven-dried jerky might have a different doneness profile than those air-dried. The specific temperature and time of the cooking process directly affect the final product. For example, a jerky cooked at a lower temperature for a longer time will likely have a more tender texture than jerky cooked at a higher temperature for a shorter time.

These differences in cooking methods should be accounted for when assessing doneness.

Influence of Spices on Doneness Indicators

Spices play a critical role in defining the flavor and texture of jerky. Different spices require varied drying times to fully develop their aroma and flavor. Spices like paprika, for example, might need a shorter drying time to retain their vibrancy. Conversely, certain spices might need longer drying times to release their full flavor and aroma, affecting the desired doneness.

The combination of spices further impacts the ideal drying point. A jerky recipe containing a mixture of spices might require adjustments to the drying time to ensure that all spices are properly integrated and contribute to the overall flavor.

Troubleshooting: How To Tell When Beef Jerky Is Done

Perfecting jerky requires understanding potential pitfalls and how to navigate them. This section delves into common issues and provides practical solutions to ensure your jerky turns out consistently delicious. From chewy to hard, we’ll equip you with the knowledge to fine-tune your cooking process.Common issues in jerky production often stem from deviations in cooking time or temperature. Understanding these variations is crucial for achieving the desired texture and taste.

Addressing these issues involves adjusting the cooking time and temperature, and understanding the relationship between drying time and doneness.

Common Doneness Problems and Solutions

Consistent jerky production requires meticulous attention to the cooking process. Problems like jerky that is too chewy or too hard often stem from improper timing or temperature management.

- Jerky Too Chewy: Undercooked jerky retains significant moisture content. This results in a chewy texture. Adjusting the cooking time, and potentially increasing the drying time is often required. To mitigate this, increase the drying time or cook the jerky for a longer duration, monitoring closely with a meat thermometer.

- Jerky Too Hard: Overcooked jerky loses too much moisture. This leads to a tough, dry, and hard texture. If you notice your jerky is becoming too hard during cooking, reduce the cooking time immediately and increase the drying time. In this scenario, re-adjusting the cooking time is paramount.

Adjusting Cooking Time Based on Doneness

Precisely gauging the doneness of your jerky is critical for avoiding over- or undercooking. Monitoring with a thermometer and adapting the cooking time according to your findings is essential.

- Monitoring with a Thermometer: Use a meat thermometer to monitor internal temperature throughout the cooking process. A consistent internal temperature range, often between 140°F (60°C) and 160°F (71°C), is generally desired for achieving optimal results. Note that variations in recipe and desired final product texture might necessitate a different target temperature.

- Adjusting based on Observed Doneness: If the jerky is too chewy, increase the cooking time, keeping a close eye on the internal temperature. Conversely, if the jerky is too hard, reduce the cooking time. Monitoring the moisture content throughout the cooking process is also crucial.

Preventing Overcooking or Undercooking

Consistent cooking and careful monitoring are essential to prevent overcooking or undercooking. Understanding the relationship between cooking time and moisture loss is paramount.

- Preventing Overcooking: Avoid leaving jerky in the cooking process for extended periods. Continuous monitoring is essential. Overcooking can result in jerky that is dry and brittle.

- Preventing Undercooking: Undercooked jerky is prone to being chewy and potentially unsafe to consume. Ensure that the internal temperature reaches the target range, and closely monitor the process to prevent undercooking.

Ending Remarks

So, there you have it – the complete guide to nailing that perfect beef jerky. Mastering these techniques will transform your jerky from a sometimes-hit-or-miss endeavor into a guaranteed delicious treat. Remember to consider the recipe, thickness, and drying time to fine-tune your approach. Happy jerky making!

Common Queries

What’s the ideal internal temperature for beef jerky?

The safe internal temperature for beef jerky is generally 160-170°F (71-77°C), but the exact range depends on the specific recipe and desired texture.

How do I prevent my jerky from getting too chewy?

Over-drying is the main culprit. Pay close attention to the drying time and monitor the texture regularly.

Can I use different types of thermometers for checking jerky doneness?

Yes, instant-read and digital probe thermometers are both suitable. Instant-read thermometers are faster, but probe thermometers offer more continuous monitoring.

How does the thickness of the jerky affect the drying time?

Thicker jerky takes longer to dry than thinner jerky. The thickness significantly influences the drying time and thus the final doneness.