How to make pine wood flooring is a rewarding DIY project, transforming a space with natural beauty and warmth. This guide dives into the meticulous steps, from selecting the perfect pine to achieving a polished, professional finish. Prepare to embark on a journey of wood, measurement, and masterful installation.

Choosing the right pine, preparing a stable subfloor, precise cutting, and a stylish finish are key components in achieving stunning results. This guide will walk you through every stage, offering expert advice and practical tips to ensure your pine wood flooring project is a resounding success.

Choosing Pine Wood Flooring

Pine wood flooring offers a natural, affordable, and versatile option for homeowners. Its availability in various species, grades, and treatment options allows for customization to suit diverse aesthetic preferences and budget constraints. Understanding the nuances of different pine types, grades, and their impact on longevity is crucial for making an informed decision.Pine wood flooring is a popular choice for its relatively low cost compared to hardwoods, its warm aesthetic, and its adaptability to different design styles.

However, the durability and longevity can vary significantly based on the species, grade, and treatment.

Types of Pine Wood

Different pine species exhibit varying characteristics. Understanding these differences is key to selecting the right flooring for your project. The most common types used for flooring include:

- Eastern White Pine: Known for its soft texture, straight grain, and light color. It’s generally less dense than other pine types, which can affect its durability. Its affordability makes it a popular choice for budget-conscious homeowners.

- Southern Yellow Pine: Characterized by a slightly darker color and a more pronounced grain pattern than Eastern White Pine. It’s generally denser and more durable, offering better resistance to dents and scratches. This resilience translates to a longer lifespan, but it comes at a higher cost.

- Ponderosa Pine: This variety is known for its reddish-brown color and distinctive, often interlocked, grain patterns. It’s more dense and thus more resistant to wear and tear compared to Eastern White Pine, making it a good option for high-traffic areas. It typically has a slightly higher cost compared to Eastern White Pine.

Grades of Pine Wood Flooring

Pine wood flooring is categorized into different grades based on its quality and appearance. These grades significantly impact the final aesthetic and long-term performance of the floor.

- Select Grade: This grade boasts the best visual appeal, with minimal knots, imperfections, and variations in color. It’s the highest quality and, consequently, the most expensive.

- Number 1 Grade: While still visually appealing, this grade may contain some minor imperfections like small knots or slight color variations. It strikes a balance between quality and cost.

- Number 2 Grade: This grade can exhibit more pronounced imperfections like larger knots, more significant color variations, and minor defects. It is generally the most affordable option.

Pros and Cons of Different Pine Woods

| Pine Type | Pros | Cons |

|---|---|---|

| Eastern White Pine | Affordable, soft underfoot, light color | Less durable, susceptible to scratches and dents, potentially shorter lifespan |

| Southern Yellow Pine | More durable than Eastern White Pine, better resistance to wear and tear, slightly darker color | Higher cost, can have more pronounced grain patterns |

| Ponderosa Pine | Denser than Eastern White Pine, more resistant to damage, visually appealing | Higher cost than Eastern White Pine, may require more finishing |

Cost Comparison

The cost of pine wood flooring varies significantly depending on the species, grade, and finishing. Eastern White Pine is generally the most affordable, while Ponderosa Pine tends to be the most expensive. Consider your budget and the desired aesthetic when making your selection.

Climate Considerations

The climate in which the flooring will be installed plays a vital role in its longevity. High humidity or extreme temperature fluctuations can lead to warping, cracking, or other damage. Consult with a flooring professional to determine the best pine type for your specific climate.

Preparing the Subfloor: How To Make Pine Wood Flooring

Proper subfloor preparation is crucial for the longevity and aesthetic appeal of pine wood flooring. A stable, level, and structurally sound subfloor ensures the flooring will remain in place, minimizing the risk of squeaks, gaps, or unevenness over time. This step sets the foundation for a beautiful and durable installation.A well-prepared subfloor significantly impacts the overall quality of the finished flooring.

It reduces the potential for future problems, such as buckling, gaps, or squeaking, and contributes to a more comfortable and aesthetically pleasing living space. The process involves careful inspection, leveling, and waterproofing to guarantee a flawless installation.

Subfloor Inspection and Structural Integrity

A thorough inspection of the existing subfloor is essential before laying new flooring. This inspection should focus on identifying any structural issues that could compromise the flooring’s stability. Look for signs of rot, warping, or significant damage. Uneven surfaces, such as significant dips or protrusions, need to be addressed to ensure a level installation. Any issues should be corrected before proceeding with the installation of the underlayment and flooring.

Subfloor Leveling and Stability

Achieving a level subfloor is paramount for a smooth and stable installation. Significant variations in the subfloor’s elevation can lead to uneven flooring, which can create tripping hazards and negatively affect the aesthetic appeal of the finished product. Employing appropriate leveling techniques, such as using shims or self-leveling compounds, is crucial for ensuring a uniform surface. This ensures that the flooring sits at a consistent level across the entire installation area.

Subfloor Materials

Different types of subfloors are suitable for pine wood flooring, each with its own advantages and disadvantages. Plywood is a common choice due to its stability and ability to create a level surface. Concrete subfloors, while often requiring additional preparation, provide a strong and durable foundation. The choice of subfloor material depends on the existing structure and the specific requirements of the project.

Subfloor Installation and Waterproofing

Proper installation of the chosen subfloor material is critical for its effectiveness. Follow the manufacturer’s instructions for specific installation procedures. Secure the subfloor to the joists or supporting structure to prevent movement and ensure stability. Waterproofing the subfloor is crucial in areas prone to moisture or water leaks. This step prevents moisture from penetrating the subfloor, which could cause damage to the flooring and lead to health issues.

Use appropriate moisture barriers or waterproof membranes to prevent moisture issues.

Subfloor Preparation Procedure

This step-by-step procedure Artikels the necessary steps for checking and preparing a subfloor for pine wood flooring installation.

- Inspect the Subfloor: Carefully examine the existing subfloor for any signs of damage, rot, or structural issues. Note any significant dips or protrusions that need addressing.

- Level the Subfloor: Use shims, self-leveling compounds, or other appropriate methods to ensure a level surface. Leveling is crucial for a smooth and stable flooring installation.

- Install Underlayment (Optional): If using an underlayment, follow the manufacturer’s instructions for proper installation. This layer adds cushioning and helps with soundproofing.

- Waterproofing (if needed): Apply a moisture barrier or waterproof membrane to prevent moisture from damaging the subfloor and the new flooring.

- Secure the Subfloor: Secure the subfloor to the joists or supporting structure to prevent movement and ensure stability.

- Inspect and Verify: Thoroughly inspect the prepared subfloor for any remaining issues before proceeding with the flooring installation.

Measuring and Cutting the Wood

Accurately measuring and cutting pine wood flooring is critical for a professional-looking installation. Precise measurements ensure that the flooring fits seamlessly and minimizes waste, saving you money and time. This section details the process, including techniques and tools, for achieving a flawless result.Careful planning and execution during the measuring and cutting stages will significantly impact the overall quality and aesthetic appeal of your finished project.

This meticulous approach avoids costly errors and ensures a smooth, professional installation.

Room Measurement Process

Accurate room measurements are foundational for a successful flooring project. A detailed plan will help prevent errors and wasted material. Using a measuring tape, carefully measure the length and width of each room section. Pay close attention to any obstacles or irregularities in the room’s dimensions, such as doorways, fireplaces, or changes in wall angles. Double-check your measurements to avoid costly mistakes.

Create a detailed diagram or blueprint of the room layout, noting any specific locations or design elements that require particular attention, such as alcoves, or rooms with complex shapes.

Cutting Techniques Comparison

Selecting the appropriate cutting technique depends on factors such as the size of the project, available tools, and personal preferences. A well-informed decision regarding the tools will save time and effort.

| Cutting Technique | Pros | Cons | Suitability |

|---|---|---|---|

| Hand Saw (e.g., Rip Saw, Coping Saw) | Precise control, suitable for intricate cuts, relatively inexpensive | Slow, physically demanding, less efficient for large projects | Smaller projects, intricate designs, when accuracy is paramount |

| Power Saw (e.g., Circular Saw, Table Saw) | Fast, efficient for large projects, greater accuracy | Can be expensive, requires safety precautions, less control over intricate cuts | Large projects, straight cuts, efficiency prioritized |

The table above provides a comparative analysis of various cutting techniques, highlighting their strengths and weaknesses. Careful consideration of project scale and desired outcome is crucial in selecting the most suitable method.

Efficient Cutting Strategies

Minimizing waste is crucial for maximizing efficiency and reducing costs in a flooring project. Several strategies can help in this endeavor.

- Layout Planning: Carefully plan the layout of the flooring boards to minimize the amount of offcuts. Consider the grain direction and pattern for aesthetic appeal and minimize waste. Using software or online tools to visualize the layout can assist in this process.

- Cut to Length Strategies: Cutting boards to the exact required length, using a marking gauge and a measuring tape, prevents unnecessary waste and maximizes material utilization. Measure twice, cut once!

- Using a Straight Edge: Using a straight edge or a straightedge, ensures consistent cuts, especially for long runs. This will reduce inconsistencies in the finished product.

- Pre-cut and Storage: Pre-cut boards to the required lengths before installation to minimize on-site cutting and potential mistakes. Store pre-cut pieces carefully to maintain their integrity.

Implementing these strategies will minimize the amount of waste generated, ultimately saving time and money.

Importance of Precise Measurements

Precise measurements are essential for a professional-looking finish. Variations in measurements can lead to gaps, overlaps, or inconsistencies in the flooring. Achieving a seamless and visually appealing installation relies on accurate measurements. Small errors can accumulate and result in noticeable gaps or inconsistencies, significantly impacting the final aesthetic of the flooring.

Tools for Accurate Measurements and Cutting

Utilizing the right tools is paramount for a successful flooring project. A range of tools, each with its specific purpose, can help ensure accuracy.

- Measuring Tape: Essential for accurate measurements of the room dimensions and individual boards.

- Marking Gauge: Used to mark the exact cutting points on the wood.

- Straight Edge: Ensures straight cuts for even installation.

- Pencil: For marking the cutting lines on the wood.

- Hand Saw (or Power Saw): Depending on the size and complexity of the project.

Using these tools correctly and consistently will lead to precise cuts and a professional-looking finish.

Installing the Flooring

Pine wood flooring installation, when done correctly, yields a beautiful and durable finished product. Careful attention to detail, proper preparation, and adherence to the correct techniques are crucial for a long-lasting, aesthetically pleasing result. This section details the installation process, from adhesive selection to safety precautions.

Adhesive Selection and Application

Choosing the right adhesive is paramount for a strong and stable floor. Different adhesives cater to various subfloor types and installation methods. A good adhesive ensures the flooring stays put and prevents movement or warping over time.

- Polyurethane Adhesive: This versatile adhesive is often favored for its ability to adhere to both wood and concrete subfloors. It provides a strong bond, is relatively easy to apply, and is suitable for most pine wood flooring installations. The key to using polyurethane adhesive effectively is applying it evenly and thoroughly to both the subfloor and the back of the flooring planks.

- Epoxy Adhesive: Epoxy adhesives are ideal for situations where exceptional strength and resistance to moisture are critical. They are often used in high-moisture environments or when extra durability is desired. Epoxy adhesives require precise application and are typically more expensive than polyurethane adhesives.

- Contact Cement: This type of adhesive creates a strong bond by adhering the flooring directly to the subfloor. It is best used when the subfloor is completely level and free from imperfections. Contact cement is known for its quick-drying nature and is often favored for its speed in installation. However, improper application can lead to unevenness in the flooring, so precision is key.

Securing the Flooring to the Subfloor

Various methods can secure the flooring to the subfloor, each with its own advantages and considerations. The chosen method should align with the adhesive used and the overall installation plan.

- Stapling: Stapling is a common method for securing flooring, especially in situations where the subfloor is already stable. The spacing and depth of the staples are crucial to avoid damage to the flooring or subfloor. Using the appropriate stapler and staple size is essential for a professional look.

- Nailing: Similar to stapling, nailing offers a reliable method of securing the flooring to the subfloor. Appropriate nails and a nail gun are essential for precise and secure fastening. The type of nail should be chosen based on the thickness of the flooring and the subfloor.

- Click-Lock Systems: Click-lock systems offer a more streamlined installation process. These systems typically involve interlocking grooves and tongue-and-groove designs on the planks. These systems are often faster to install and can minimize the risk of gaps and inconsistencies.

Spacing and Expansion Gaps

Proper spacing and expansion gaps are vital for the long-term stability and appearance of the flooring. These gaps allow the wood to expand and contract naturally due to temperature and humidity changes without causing buckling or cracking.

- Importance of Gaps: Neglecting expansion gaps can lead to significant issues like warping, cracking, or lifting of the flooring. This is a common problem if the flooring is installed in a climate with significant temperature fluctuations. Plan for proper spacing to accommodate these changes.

- Measuring and Marking Gaps: Measure and mark the gaps consistently throughout the installation process to ensure uniform spacing. Use a straight edge and a marking tool to achieve precise and consistent gap sizes.

- Proper Gap Size: The recommended gap size is typically between 1/8 and 1/4 inch per 10 feet of flooring. This is crucial to prevent damage and allow for natural movement of the wood.

Achieving a Seamless Installation

A seamless installation is achieved through meticulous attention to detail at each step. This involves using proper techniques and ensuring the flooring is aligned correctly and uniformly across the entire area.

- Planking Alignment: Ensure planks are aligned precisely with the adjacent planks to avoid gaps or unevenness. Using a straight edge or a level is essential for precise alignment.

- Seamless Transitions: Transitions between different sections of the flooring, such as at doorways or stairways, should be carefully planned and executed. This will create a smooth and visually appealing flow.

- Finishing Touches: The final step is to add any necessary finishing touches, such as applying a sealant or varnish to protect the flooring and enhance its appearance. This is critical to preserving the beauty and durability of the floor.

Safety Precautions

Safety should be paramount during the installation process. Using the appropriate safety gear and following proper procedures can prevent injuries.

- Protective Gear: Wear safety glasses, gloves, and appropriate footwear to protect yourself from splinters, dust, and other potential hazards.

- Lifting and Handling: Use proper lifting techniques when handling flooring planks to avoid injury and damage to the planks.

- Work Environment: Ensure the work area is well-lit and ventilated to minimize the risk of accidents or health issues.

Finishing the Flooring

Completing the installation of your pine wood flooring involves a crucial step: applying a finish. This step not only protects the wood from damage and wear but also enhances its natural beauty, creating a lasting and aesthetically pleasing surface. Proper finishing significantly impacts the longevity and visual appeal of your flooring.Applying a suitable finish to your pine wood flooring is essential to safeguard the wood from moisture, stains, scratches, and other forms of damage.

A well-finished floor will retain its beauty and resilience for many years, making it a worthwhile investment in your home’s interior.

Finishing Options for Pine Wood Flooring

Various finishing options are available for pine wood flooring, each offering unique benefits and drawbacks. Understanding the different types will help you make an informed decision based on your specific needs and preferences.

- Staining:

- Sealing:

- Varnishing:

- Oiling:

Staining is a popular choice for enhancing the natural beauty of pine wood. It allows you to customize the color of your flooring to complement your decor. Stains can penetrate the wood, providing a more integrated look compared to surface finishes. The selection of stains is vast, offering a wide array of colors and tones.

Sealing protects the wood from moisture and stains, but it doesn’t significantly alter the wood’s color. Sealing is often used as a preliminary step before staining or as a stand-alone option. It creates a protective barrier that prevents water and other liquids from penetrating the wood’s surface, thus preventing damage.

Varnishing creates a hard, protective layer on the wood’s surface. It offers excellent durability and resistance to scratches and scuffs. Varnishes come in different levels of gloss, allowing for various aesthetic effects. A high-gloss varnish provides a mirror-like finish, while a matte varnish offers a more subdued look.

Oiling is a popular choice for its ability to enhance the natural beauty of the wood. It penetrates the wood’s surface, creating a protective layer that resists water and stains. Oiling can also provide a beautiful, warm, and natural look, allowing the wood grain to shine through. Oiling often requires periodic reapplication to maintain its protective properties.

Importance of Proper Finishing

Proper finishing is critical for protecting pine wood flooring. A well-applied finish creates a durable barrier against moisture, stains, and everyday wear and tear. This protection not only extends the life of the flooring but also helps maintain its aesthetic appeal. The longevity of the flooring and the upkeep required over time are significantly impacted by the quality and method of finishing.

Durability and Aesthetic Qualities of Different Finishes

The durability and aesthetic qualities of different finishes vary considerably. The choice of finish should be aligned with the expected level of traffic and the desired aesthetic. For high-traffic areas, a more durable finish is recommended. The visual appeal of a finish can also affect the overall aesthetic of a room.

Preparation Steps Before Applying the Finish

Thorough preparation before applying a finish is crucial for a successful and long-lasting result. The preparation steps ensure a smooth, even finish that adheres properly to the wood.

- Cleaning:

- Sanding:

- Inspection:

Thoroughly clean the wood surface to remove any dust, debris, or old finishes. A clean surface ensures that the new finish adheres properly.

Sanding smooths out any imperfections or irregularities in the wood’s surface. This step is essential for a uniform finish application. Proper sanding helps create a consistent surface, ensuring a uniform finish.

Inspect the wood for any cracks, chips, or other imperfections. Addressing these issues before finishing is essential to prevent further damage. A thorough inspection will help prevent issues from arising later.

Comparison Table of Finishing Options

| Finish | Pros | Cons |

|---|---|---|

| Staining | Enhances natural beauty, customizable colors, penetrates wood | Can be difficult to repair minor damage, may require multiple coats |

| Sealing | Protects against moisture and stains, easy to apply | Doesn’t alter wood color significantly, may not provide high durability |

| Varnishing | High durability, resistant to scratches and scuffs, various gloss levels | Can be more expensive than other options, may yellow over time |

| Oiling | Enhances wood grain, natural look, penetrates wood | Requires periodic reapplication, can be susceptible to water damage |

Troubleshooting and Maintenance

Pine wood flooring, while beautiful and durable, requires proper care and attention to maintain its appearance and longevity. Understanding potential issues and their solutions, along with regular maintenance practices, is crucial for maximizing the lifespan of your investment. This section provides a comprehensive guide to troubleshooting common problems and preserving your pine wood floors.Maintaining the quality of pine wood flooring involves more than just occasional cleaning.

A proactive approach, including preventive measures and prompt responses to minor damages, significantly impacts the flooring’s overall lifespan and aesthetic appeal.

Common Installation Problems and Solutions

Proper installation is foundational to the longevity of any flooring. Incorrect installation can lead to a variety of issues, from minor imperfections to more significant structural problems. Addressing these issues promptly and correctly can prevent further damage and costly repairs.

- Gaps and Unevenness: Uneven subfloors or improper nailing/gluing can result in gaps or unevenness in the flooring. Solutions include re-leveling the subfloor, ensuring proper nailing or gluing techniques, and using shims to create a level surface for the flooring.

- Cupping or Buckling: Changes in humidity or improper subfloor preparation can cause pine wood planks to cup or buckle. Proper subfloor moisture control and ensuring sufficient ventilation in the room are essential preventive measures. If cupping or buckling occurs, professional consultation may be necessary for complex situations.

- Squeaking or Creaking: Loose nails, shifting subfloors, or expansion and contraction of the wood due to changes in humidity can lead to squeaking or creaking sounds. Solutions involve tightening loose nails, using wood filler to address gaps, and ensuring proper ventilation.

Importance of Regular Maintenance

Regular maintenance is critical to preserving the beauty and durability of pine wood flooring. Consistent care prevents damage, extends the life of the flooring, and keeps it looking its best.

- Regular Cleaning: Regular cleaning helps prevent dirt and debris from accumulating and damaging the wood’s finish. This can also prevent the growth of mildew and mold, which can be particularly problematic in areas with high humidity.

- Preventing Water Damage: Pine wood is susceptible to water damage. Implementing measures to prevent spills and leaks, and ensuring proper ventilation, are critical to maintaining the flooring’s integrity. Use appropriate protection during cleaning, like placing mats near sinks and doorways to prevent spills from penetrating the wood.

- Addressing Humidity Changes: Pine wood expands and contracts with changes in humidity. Maintaining a stable humidity level within the room is essential for preventing warping, buckling, and other issues.

Cleaning and Caring for Pine Wood Flooring

Proper cleaning and care procedures are essential for maintaining the aesthetic appeal and longevity of your pine wood flooring.

- Vacuuming: Regular vacuuming helps remove dust, dirt, and debris from the surface, preventing them from scratching the wood. A soft-bristled brush attachment is ideal for pine flooring.

- Damp Mopping: For deeper cleaning, use a damp mop with a mild, wood-safe cleaner. Avoid excessive water, as this can damage the finish. Always test any cleaning solution in an inconspicuous area first.

- Protecting Furniture and Objects: Using protective pads underneath furniture can prevent scratches and scuffs on the flooring. This includes using area rugs to protect high-traffic areas.

Preventive Measures for Extending Flooring Life

Implementing preventive measures can significantly extend the lifespan of your pine wood flooring. These proactive steps are key to maintaining its condition and appearance.

- Using Rugs in High-Traffic Areas: Protecting high-traffic areas with rugs helps prevent excessive wear and tear on the flooring.

- Addressing Spills Immediately: Promptly addressing spills prevents staining and damage to the wood finish. Use a clean cloth or paper towel to absorb the spill and gently blot the area.

- Protecting from Excessive Moisture: Avoiding placing items directly on the flooring that could introduce excessive moisture, like wet plants or potted flowers, is important.

Repairing Minor Damages

Minor damages to pine wood flooring can often be repaired. Prompt action prevents minor problems from escalating.

- Scratches: Small scratches can be repaired with wood filler. Match the color of the filler to the wood for a seamless repair. Sand and refinish the area after the filler has dried for a professional look.

- Dents: Dents can sometimes be addressed using a combination of wood filler and sanding. However, deeper dents may require professional repair. Use caution when dealing with deeper damage.

Visual Aids

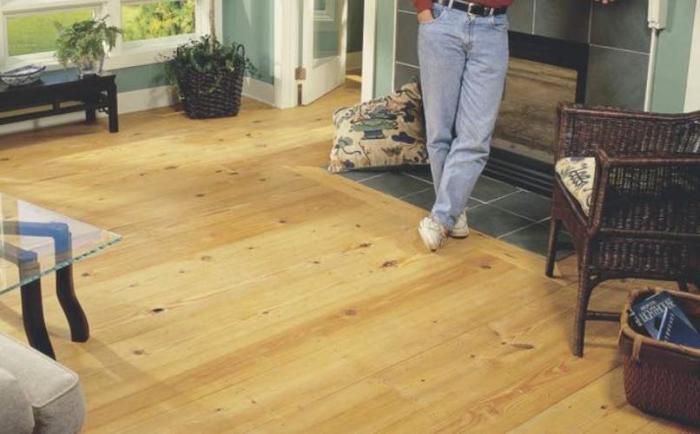

Pine wood flooring offers a wide range of visual possibilities, transforming a room from simple to sophisticated. Understanding the potential patterns, designs, and how lighting interacts with the wood is crucial to achieving the desired aesthetic. This section explores the various visual options available and how to choose the right look for your space.

Patterns and Designs

Pine flooring’s natural beauty lends itself to various patterns and designs. Understanding these options allows you to create a personalized look for your home. Herringbone, a classic pattern, creates a sophisticated and visually appealing effect, often seen in traditional or modern interiors. Parquet, with its intricate geometric designs, offers a more formal and elegant look, adding depth and texture to the room.

More contemporary designs include planks arranged in a staggered or random pattern, which provides a warmer and more inviting atmosphere.

Flooring Projects with Different Styles, How to make pine wood flooring

Visual inspiration is key when selecting flooring. Consider projects showcasing a range of styles and aesthetics. A rustic cabin might feature wide, natural pine planks with minimal finishing, emphasizing the wood’s natural beauty. A modern living room could benefit from a contemporary design with planks in a neutral tone, complemented by sleek furniture and accessories. A classic dining room could be enhanced by herringbone-patterned pine flooring, creating a warm and inviting atmosphere.

These visual cues help in making informed decisions.

Room Design and Flooring Styles

The table below illustrates how different pine wood flooring styles can complement various room designs:

| Room Design | Pine Wood Flooring Style | Description |

|---|---|---|

| Rustic Cabin | Wide planks, natural finish | Emphasizes the natural beauty of the wood, creating a warm and inviting atmosphere. |

| Modern Living Room | Contemporary design, neutral tones | Offers a sleek and sophisticated look, blending seamlessly with contemporary furniture and accessories. |

| Classic Dining Room | Herringbone pattern | Creates a warm and inviting atmosphere, adding depth and texture to the room. |

| Contemporary Kitchen | Planks in a staggered or random pattern, neutral tones | Provides a clean and modern look, complementing modern appliances and cabinetry. |

| Traditional Bedroom | Parquet, intricate designs | Adds elegance and sophistication to the room, creating a warm and inviting atmosphere. |

Impact of Lighting on Pine Wood Flooring

Lighting plays a significant role in enhancing the visual appeal of pine wood flooring. Natural light highlights the wood’s natural grain and color variations, creating a warm and inviting ambiance. Different types of lighting can emphasize different aspects of the flooring. Warm, ambient lighting can enhance the natural tones of the wood, while cool lighting can bring out the subtle variations in color.

Careful consideration of lighting can dramatically affect the overall look and feel of the room.

Enhancement of Room Ambiance

Pine wood flooring, with its versatility, can significantly enhance a room’s ambiance. The natural warmth of the wood creates a cozy and inviting atmosphere, ideal for family gatherings or relaxing evenings at home. The different patterns and finishes available offer various options to complement different interior design styles, creating a cohesive and visually appealing space. The natural texture of pine can add a touch of rustic charm or a sophisticated elegance, depending on the chosen design and finishes.

Final Summary

From selecting the ideal pine planks to achieving a flawless finish, this comprehensive guide equips you with the knowledge and strategies for a stunning pine wood flooring project. Remember, meticulous preparation and attention to detail are the cornerstones of a beautiful, long-lasting floor. Enjoy the fruits of your labor! Your home will thank you.

FAQ Overview

What are the most common types of pine wood suitable for flooring?

Several pine species excel as flooring, each with unique characteristics. Examples include Ponderosa Pine, known for its durability, and Eastern White Pine, valued for its soft, even grain. Research specific varieties to find the best match for your project.

How can I ensure the subfloor is properly prepared before installing pine wood flooring?

A level and stable subfloor is crucial for long-lasting flooring. Thoroughly inspect the subfloor for structural integrity, address any irregularities, and ensure it’s adequately waterproofed to prevent moisture issues. Consider using plywood or concrete, depending on your existing structure.

What are some common mistakes to avoid when cutting pine wood flooring?

Inaccurate measurements lead to costly mistakes. Always double-check your measurements, and use sharp tools for clean cuts. Employ efficient cutting techniques to minimize waste. A professional-looking finish hinges on precision.

What are some of the most popular finishes for pine wood flooring?

Staining, sealing, and varnishing are popular finishing options. Each finish provides distinct protection and aesthetic qualities. Thorough preparation before application is paramount for a beautiful and lasting finish. Refer to the pros and cons table in the guide for detailed comparisons.