How to wire twin EDF setup is a crucial skill for anyone working with Ethernet Data Fiber systems. This guide provides a comprehensive overview, from understanding the components and wiring schemes to troubleshooting common issues and maintaining optimal performance. Discover the secrets to successful twin EDF installations and avoid costly errors.

This detailed guide will walk you through the entire process, ensuring a strong and reliable connection. We’ll cover everything from cable types and connector choices to precise wiring diagrams and troubleshooting techniques.

Understanding Twin EDF Setup

The proliferation of twin Ethernet Data Fiber (EDF) setups, while seemingly offering enhanced bandwidth and resilience, often masks underlying complexities and potential vulnerabilities. This analysis delves into the intricate workings of twin EDF, highlighting the crucial factors that dictate its effectiveness and the pitfalls that can compromise its reliability. A critical understanding is essential to navigate the political and economic implications of adopting this technology.The adoption of twin EDF, frequently touted as a solution to network bottlenecks, often glosses over the inherent trade-offs.

This complexity is amplified by the various implementation choices, each with its own set of advantages and disadvantages, creating a landscape ripe for miscalculation and, potentially, exploitation.

Twin EDF Components and Functions

Twin EDF setups rely on a redundant fiber optic cabling system, offering enhanced network resilience. The core components include two separate fiber optic cables, each capable of transmitting data independently. Crucially, this redundancy aims to mitigate single-point failures, a key vulnerability in many current infrastructure designs. Crucially, this redundancy is often presented as a guaranteed solution, ignoring the complex interplay of network management and the potential for human error.

Types of Twin EDF Cables and Connectors

Numerous types of twin EDF cables and connectors exist, each tailored to specific applications. Optical fiber types, like single-mode and multi-mode, directly impact transmission distance and bandwidth capabilities. Different connector types, such as SC, LC, or ST, influence the ease of installation and maintenance. The choice of cable and connector must align with the specific environmental conditions and anticipated data transmission demands.

Failure to consider these variables can lead to costly upgrades or, worse, systemic network failures.

Wiring Schemes in Twin EDF Installations

Different wiring schemes are employed in twin EDF installations, each with its own set of advantages and disadvantages. One common scheme involves a redundant path, with data transmitted simultaneously over both fibers. Another scheme might involve a backup path, where one fiber carries data while the other stands idle until needed. These variations, often driven by cost considerations or regulatory constraints, can have a profound impact on the overall network’s resilience.

Environmental Considerations for Twin EDF Wiring

The selection of wiring methods for twin EDF installations must consider the environment. Indoor installations, characterized by controlled temperature and humidity, often allow for more flexible wiring options compared to outdoor environments. Outdoor installations, facing fluctuating temperatures, moisture, and potential physical damage, necessitate robust and shielded cabling. The choice of wiring method, frequently influenced by political pressures and economic incentives, dictates the long-term sustainability and security of the network.

Failure to account for environmental factors can lead to premature equipment failure and costly repairs.

Key Considerations for Selecting Wiring Methods

Several key considerations guide the selection of appropriate wiring methods for different environments. These factors include the anticipated data transmission rates, the required transmission distance, and the overall budget. Furthermore, the potential for future expansion, often overlooked in short-term cost analyses, should be taken into account. Political agendas and regulatory pressures can heavily influence the decision-making process, leading to suboptimal solutions.

Wiring Procedures and Diagrams

The intricacies of wiring a twin EDF setup often mask the underlying vulnerabilities. Poorly executed connections can lead to catastrophic failures, jeopardizing both the aircraft and the operator. A methodical approach, coupled with meticulous attention to detail, is paramount. Ignoring these crucial steps is a recipe for disaster, potentially resulting in severe consequences.This section dissects the wiring process, providing a comprehensive understanding of the critical steps and potential pitfalls.

Understanding the nuances of wiring diagrams and termination techniques is essential for ensuring safe and reliable operation. A robust wiring setup is the cornerstone of any successful EDF system, mitigating the risks associated with faulty connections.

Step-by-Step Installation Procedure

A systematic approach is crucial for a successful twin EDF installation. Each step, from preparing the components to securing the final connections, contributes to the overall safety and performance of the system. Skipping steps or rushing through the process compromises the integrity of the setup, potentially leading to unforeseen issues.

- Carefully inspect all components for damage or defects. Ensure the wires, connectors, and other parts are intact and free from any signs of wear or tear.

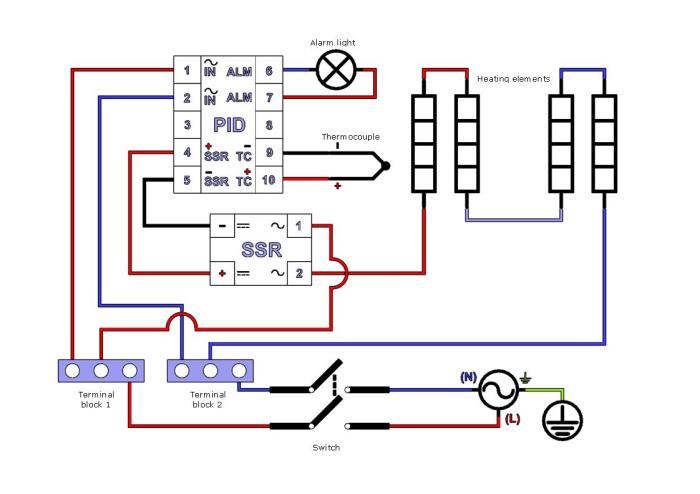

- Thoroughly examine the provided wiring diagrams. Understanding the intended connections and the specific pinouts of the connectors is paramount for a successful installation.

- Identify the positive (+) and negative (-) terminals on each EDF motor and the receiver. Proper identification is crucial for ensuring the correct polarity.

- Using appropriate crimp tools, securely connect the wires to the connectors. This step necessitates careful attention to ensure a strong and reliable connection, preventing potential issues.

- Verify all connections using a multimeter to ensure continuity and proper polarity. This crucial step guarantees the correct electrical pathways are established.

- Securely mount the connectors to the respective components using appropriate mounting hardware. This step ensures the longevity and reliability of the connection.

- Thoroughly test the system after the installation. This step helps in identifying any potential issues, such as short circuits or mismatched connections, before deployment.

Wiring Diagrams for Common Configurations

The wiring configuration varies based on the specific receiver and EDF setup. Understanding these differences is crucial for a proper installation. Different designs have different potential failure points, highlighting the importance of meticulous attention to detail.Twin EDF setups typically employ a configuration where the transmitter sends signals to the receiver, which then controls the motors. Specific pinouts and colors vary by manufacturer.

Consult the manufacturer’s manuals for the specific diagrams for the components being used. Generic diagrams are insufficient for a safe and reliable system.

Color Coding and Signal Assignments, How to wire twin edf setup

Consistent color coding is essential for identifying signals and ensuring proper connections. Inconsistent color schemes are a major source of errors.

| Wire Color | Signal | Description | Connection Point |

|---|---|---|---|

| Orange | TX+ | Transmit positive | Transmitter |

| White | TX- | Transmit negative | Transmitter |

| Red | Motor+ | Motor positive | EDF Motor |

| Black | Motor- | Motor negative | EDF Motor |

Troubleshooting Wiring Errors

Troubleshooting wiring issues in twin EDF setups requires a systematic approach. Identifying the source of the problem quickly minimizes downtime and reduces the risk of further damage.

- Check for loose or damaged connections. Tighten connections and replace any damaged components to ensure a reliable system.

- Verify the polarity of all connections. Incorrect polarity can cause the motors to not function correctly or malfunction.

- Use a multimeter to check for continuity and voltage drops across connections. This method helps in pinpointing faulty connections.

- Compare the wiring diagram with the actual connections to identify any discrepancies. A mismatch can cause unintended behavior and failures.

- If issues persist, consult the manufacturer’s documentation or a qualified technician. Seeking expert help can save time and prevent further complications.

Troubleshooting and Maintenance: How To Wire Twin Edf Setup

The delicate dance of twin EDF setups, while offering impressive performance, demands meticulous attention to detail. Ignoring preventative measures and prompt troubleshooting can lead to catastrophic failures, potentially resulting in costly repairs or even personal injury. This section will delve into the critical aspects of identifying, diagnosing, and resolving potential issues, alongside outlining essential maintenance procedures.The complexities of twin EDF setups introduce numerous potential points of failure.

From faulty wiring to inadequate cooling, a multitude of factors can compromise performance or even render the system unusable. Understanding the potential issues and employing appropriate diagnostic techniques is paramount for optimizing the lifespan and reliability of the system.

Potential Issues and Diagnosis

Twin EDF setups are susceptible to a range of issues, ranging from seemingly minor problems to catastrophic failures. Poor wiring practices, inadequate cooling, and component degradation can all contribute to performance problems or outright system failure. Visual inspections are often the first line of defense, allowing for the identification of obvious signs of wear and tear or physical damage.Continuity tests are crucial for verifying the integrity of electrical connections.

These tests can detect broken wires or faulty connections that may be hidden beneath the surface, preventing unexpected and potentially dangerous failures. Signal integrity checks are equally important, particularly when dealing with complex control systems or sophisticated electronic components. These checks ensure that the signals transmitted between components are accurate and reliable.

Maintenance Procedures

Proactive maintenance is key to maintaining the optimal performance and longevity of twin EDF setups. Regular inspections and tests are essential for identifying and addressing potential problems before they escalate into major issues. The frequency of maintenance tasks should be adjusted based on usage patterns and environmental conditions. Frequent use in harsh environments necessitates more frequent maintenance to mitigate the risk of component degradation.A detailed maintenance schedule is crucial to ensure consistent upkeep and reliability.

The schedule should be tailored to the specific usage patterns and environmental factors of the setup. A table summarizing typical maintenance tasks and their recommended frequency is presented below. This table serves as a guideline and should be adjusted based on individual circumstances.

Maintenance Schedule

| Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Carefully examine all components for signs of damage, loose connections, corrosion, or unusual wear. Pay close attention to areas prone to friction or impact. |

| Continuity Test | Quarterly | Utilize appropriate test equipment to confirm the electrical continuity of all connections. This step helps identify any breaks or shorts in the wiring, a common source of malfunctions. |

| Signal Integrity Check | Semi-annually | Verify the accuracy and reliability of signals transmitted between components. This is particularly important in setups with complex control systems or sensitive electronic components. Deviations from expected values may indicate potential problems. |

| Component Inspection | Annually | Disassemble and inspect critical components for signs of wear, damage, or degradation. Look for signs of overheating, friction, or excessive stress on moving parts. |

| Environmental Check | Annually | Evaluate the environmental conditions affecting the setup, including temperature, humidity, and potential exposure to contaminants. Adjust maintenance schedules accordingly. |

Ignoring these maintenance procedures can lead to unforeseen complications and potentially catastrophic failures. The proactive approach ensures the continued reliable performance of the system and minimizes the risk of costly repairs.

Closing Summary

In conclusion, mastering how to wire twin EDF setups involves careful planning, precise execution, and proactive maintenance. By understanding the components, wiring procedures, and troubleshooting strategies Artikeld in this guide, you can confidently install and maintain a robust twin EDF system. Remember to always prioritize safety and refer to manufacturer specifications for detailed information. This knowledge will prove invaluable in various applications.

FAQ Guide

What are the common types of twin EDF cables?

Different types of twin EDF cables are available, each with varying characteristics. Choosing the right cable depends on the specific application and environmental factors. Consult the manufacturer’s specifications for guidance on selecting the most appropriate cable for your needs.

What tools are needed for a twin EDF setup?

Essential tools for a twin EDF setup include a crimping tool, cable strippers, and a multimeter for testing. Proper tools are crucial for achieving a secure and reliable connection. Always prioritize safety and use the appropriate tools for your specific application.

How can I prevent signal degradation in a twin EDF setup?

Signal degradation can be mitigated by using high-quality cables and connectors, maintaining proper termination techniques, and ensuring minimal bending or twisting of the cables. Proper installation and maintenance are key to preventing signal degradation and ensuring reliable transmission.

What is the typical lifespan of a twin EDF setup?

The lifespan of a twin EDF setup depends heavily on factors like environmental conditions, usage patterns, and the quality of maintenance. Regular maintenance and adherence to manufacturer guidelines will significantly extend the lifespan of your system.