How does BMW accelerator attach to adaptor plate? This guide breaks down the process, from the basics of accelerator function to the specific steps for different BMW models. We’ll dive into the components, materials, and safety precautions to ensure a smooth and secure installation. Get ready to master this essential automotive repair!

Understanding the specific components and their roles is key to successful installation. The adaptor plate acts as the crucial intermediary, connecting the accelerator to the engine. Different BMW models may have varying configurations, requiring tailored installation techniques. This comprehensive guide covers these nuances, ensuring a smooth and precise installation process.

Introduction to BMW Accelerator Attachment

The BMW accelerator pedal, a critical component in controlling the vehicle’s engine speed, is intricately connected to the adaptor plate. This linkage translates the driver’s input into precise engine commands, ensuring a smooth and responsive driving experience. Understanding this connection is essential for both routine maintenance and troubleshooting potential issues. A malfunctioning accelerator can lead to safety concerns and costly repairs.The accelerator assembly encompasses various components working in harmony.

These include the accelerator pedal itself, the linkage system connecting the pedal to the throttle valve, and the adaptor plate that acts as a crucial intermediary. The adaptor plate, often crafted from high-strength materials, securely mounts to the throttle body. This precise connection ensures accurate transmission of force and minimal slippage, guaranteeing optimal performance.BMW models exhibit a variety of configurations, influencing the specific design of the accelerator assembly.

Different engine types, transmission systems, and even trim levels can result in variations in the attachment method. Recognizing these nuances is crucial for accurate diagnosis and repair. Different models may employ varying materials for the adaptor plate, and the attachment methods can differ in complexity.

BMW Accelerator Assembly Variations

Different BMW models have variations in their accelerator assembly processes, impacting the overall performance and longevity of the system. These differences are crucial for accurate diagnostics and maintenance.

| Model | Accelerator Type | Adaptor Plate Material | Attachment Method |

|---|---|---|---|

| BMW 3 Series (2018-2023) | Cable-driven | Aluminum Alloy | Bolted, with a two-part mounting system for enhanced adjustability |

| BMW X5 (2020-2023) | Electronic Throttle Control (ETC) | High-strength Polymer Composite | Integrated into the throttle body; no separate adaptor plate. |

| BMW M5 (2021-2023) | ETC with performance enhancements | Carbon Fiber Reinforced Polymer (CFRP) | Direct attachment to the throttle body; complex electronic sensors integrated into the system. |

The table above illustrates a comparison of different BMW models and their accelerator assembly processes. The differences highlight the engineering considerations that go into the design of each model, tailoring the accelerator system to the specific needs and characteristics of each vehicle. Recognizing these differences is crucial for accurate diagnosis and efficient repairs.

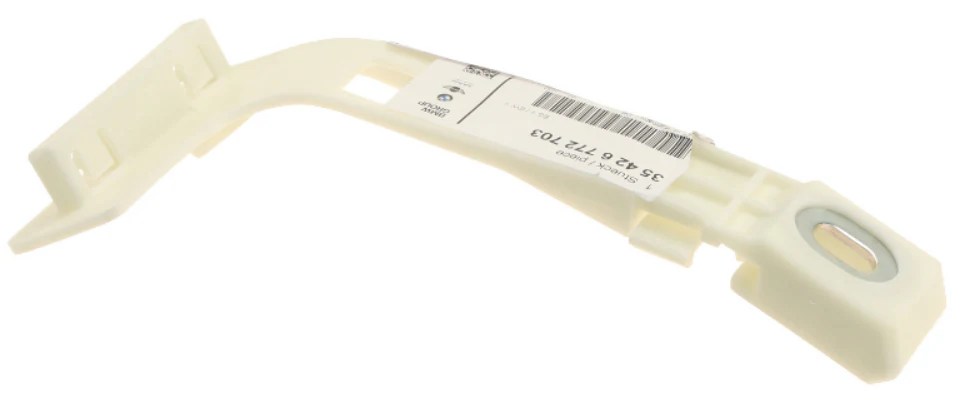

Understanding the Adaptor Plate

The BMW adaptor plate, a crucial component in the vehicle’s accelerator system, acts as a vital intermediary. It seamlessly bridges the gap between the accelerator pedal assembly and the engine’s throttle body, enabling precise control over the fuel and air mixture. Its role extends beyond mere physical connection; it plays a critical part in signal transmission and system integrity.The adaptor plate is more than just a metal plate; it’s a sophisticated engineering marvel.

Its precise design, coupled with carefully selected materials, ensures optimal performance and longevity. Understanding its features and function allows for a deeper appreciation of the complex interplay within the vehicle’s powertrain.

Key Features of a Typical BMW Adaptor Plate

The adaptor plate exhibits several critical features. These include a precisely engineered mounting surface for secure attachment to the vehicle’s chassis. Furthermore, it houses components for signal transmission, ensuring accurate and timely communication between the accelerator pedal and the engine. The plate also features integrated sealing elements to prevent leakage and maintain optimal system performance.

Role of the Adaptor Plate in the Overall System

The adaptor plate acts as a critical intermediary in the accelerator system. It facilitates the transfer of force and signal from the driver’s input to the engine’s throttle body. This intricate connection ensures smooth and responsive acceleration. A well-designed adaptor plate allows for a seamless flow of data and force, optimizing the overall driving experience.

Materials Used in Adaptor Plate Manufacturing

Various materials are employed in the fabrication of BMW adaptor plates. The choice of material directly impacts the plate’s strength, durability, and resistance to environmental factors. Common choices include high-strength steel alloys, aluminum, and sometimes, specialized polymers for specific applications. The selection process prioritizes strength and resistance to wear and tear.

Specifications of Common Adaptor Plate Designs

| Feature | Description | Dimension (approximate) | Material |

|---|---|---|---|

| Mounting Surface | Provides a precise and secure connection to the vehicle’s chassis. | Variable, dependent on specific BMW model | High-strength steel alloy |

| Signal Transmission Path | Houses components that transmit the driver’s input to the engine. | Variable, dependent on specific BMW model | High-strength steel alloy or aluminum |

| Sealing Elements | Prevents leakage of fluids and maintains system integrity. | Variable, dependent on specific BMW model | High-strength steel alloy or specialized rubber seals |

| Bolt Holes | Provides secure attachment points for mounting the adaptor plate. | Variable, dependent on specific BMW model | High-strength steel alloy |

The table above Artikels some common specifications. Keep in mind that specific dimensions and materials might vary based on the particular BMW model and year. Manufacturers prioritize precision and quality in each design to maintain peak performance and reliability.

Accelerator Attachment Process

Mastering the art of attaching a BMW accelerator to its adaptor plate is crucial for optimal performance and longevity. This process, while seemingly straightforward, demands precision and attention to detail. Following a structured approach, using the right tools, and adhering to torque specifications are paramount to achieving a secure and reliable connection.

Installation Steps

The installation process is critical for a flawless integration. A methodical approach, ensuring each step is executed correctly, is key. Carefully adhering to the prescribed steps minimizes potential issues and maximizes the longevity of your BMW’s accelerator assembly.

- Preparation: Thoroughly clean the adaptor plate and accelerator assembly to eliminate any contaminants. Ensure the surfaces are free of grease, dirt, or debris. This crucial initial step guarantees a strong, reliable bond.

- Alignment: Precise alignment is essential. Position the accelerator assembly onto the adaptor plate, ensuring all mounting points are properly aligned. Visual inspection is paramount to prevent misalignment issues.

- Initial Installation: Begin tightening the mounting bolts. Use a gentle, even pressure to avoid damaging the components. Do not overtighten initially. A moderate initial tightening helps in verifying alignment and prevents premature stress on the mounting hardware.

- Torque Specifications: Once the assembly is aligned, proceed to tightening the bolts according to the specified torque values. Refer to your BMW’s repair manual for precise torque specifications. This is crucial for a robust connection, preventing loosening or breakage over time.

Example: Tighten bolts to 10 Nm.

- Final Inspection: After all bolts are tightened, perform a final visual inspection to ensure the accelerator assembly is secure and aligned. Any misalignment or looseness should be corrected. This final check ensures a durable and reliable connection.

Installation Methods

Various installation methods exist, each with its own set of advantages and disadvantages. Understanding these methods allows for informed choices based on specific needs and resources.

- Traditional Method: This method relies on manual tightening of bolts. It is generally straightforward but requires precision and experience to avoid overtightening. The traditional approach is suitable for experienced mechanics who understand the importance of consistent pressure.

- Torque Wrench Method: Using a torque wrench ensures precise torque application, eliminating the risk of overtightening. This method is crucial for maintaining the integrity of the parts and preventing potential damage. The precision offered by torque wrenches makes them essential for ensuring the long-term reliability of the connection.

Torque Specifications

Adhering to torque specifications is critical for the durability and performance of the accelerator assembly. Incorrect torque can lead to premature failure of the components, necessitating costly repairs. The importance of adhering to specifications cannot be overstated.

Necessary Tools

| Step | Action | Tools Required | Remarks |

|---|---|---|---|

| Preparation | Cleaning surfaces | Cleaning solvents, rags | Remove contaminants for a strong bond. |

| Alignment | Verifying position | Measuring tools (e.g., ruler, calipers) | Ensure accurate positioning for proper functionality. |

| Initial Installation | Initial tightening | Screwdrivers, Wrenches | Use appropriate tools for the bolts. |

| Torque Application | Precise tightening | Torque wrench | Essential for correct torque values. |

| Final Inspection | Visual check | Eye and hands | Verify alignment and security. |

Troubleshooting and Common Issues

Navigating the intricate world of automotive modifications can sometimes lead to unforeseen challenges. Proper installation is crucial for both optimal performance and longevity. Understanding potential problems and their solutions empowers you to maintain your BMW’s accelerator attachment, ensuring smooth operation and preventing unnecessary complications.Troubleshooting effectively requires a methodical approach. Identifying the root cause of any issue is paramount.

A thorough understanding of the connection process and the components involved allows for precise diagnosis and resolution. Let’s explore common pitfalls and their corresponding remedies.

Potential Problems During Attachment

Several factors can hinder the successful attachment of the BMW accelerator to the adaptor plate. Improper alignment, inadequate torque during fastening, or damage to either the accelerator or the adaptor plate can lead to complications. Incorrect installation procedures can also introduce vulnerabilities in the connection, potentially resulting in malfunction. A precise understanding of these potential problems is vital for successful installation.

Common Causes of Faulty Connections

Faulty connections often stem from a combination of factors. Mismatched components, either due to incorrect part selection or damaged parts, can compromise the integrity of the connection. Inaccurate torque application during tightening can weaken the bond between the accelerator and the adaptor plate. Moreover, the presence of contaminants or debris within the connection points can impede the smooth operation of the accelerator.

Preventing these issues requires careful attention to detail and adherence to the manufacturer’s instructions.

Identifying and Resolving Issues

Diagnosing the problem is the first step towards resolution. Carefully examine the connection points for any visible signs of damage, misalignment, or contamination. Verify the proper torque specifications are met during tightening. If issues persist, refer to the manufacturer’s instructions for detailed troubleshooting steps.

Troubleshooting Table

| Symptom | Possible Cause | Troubleshooting Steps | Resolution |

|---|---|---|---|

| Accelerator pedal feels unresponsive or sluggish | Loose connection between the accelerator and adaptor plate; damaged accelerator cable or wire | Check for proper alignment and torque. Inspect the accelerator cable or wire for any signs of damage or kinks. Ensure the adaptor plate is securely mounted to the throttle body. | Tighten the connection; replace the damaged cable or wire; ensure the adaptor plate is firmly seated. |

| Accelerator pedal is jerky or erratic | Misaligned accelerator cable or wire; damaged connection points; incorrect torque application | Inspect the alignment of the accelerator cable or wire. Verify the connection points are clean and free of debris. Re-torque the connection points, adhering to the manufacturer’s specifications. | Correct alignment of the cable or wire; clean the connection points; re-torque with the correct torque. |

| Accelerator pedal doesn’t return to the neutral position | Stuck or binding accelerator cable or wire; worn out return spring; faulty mounting points | Inspect the accelerator cable or wire for any obstructions. Check the return spring for wear or breakage. Ensure all mounting points are secure. | Remove any obstructions from the cable or wire; replace the return spring if needed; ensure all mounting points are firmly fixed. |

| Electrical issues with the accelerator | Faulty wiring connections; damaged wiring; incorrect wiring harness | Verify all wiring connections are secure and properly connected. Check for any signs of damage to the wiring. Compare the wiring with the installation manual to ensure proper harness connections. | Secure all wiring connections; replace any damaged wiring; confirm wiring conforms to the installation manual. |

Safety Precautions During Installation

Installing a BMW accelerator and its adaptor plate requires meticulous attention to safety. A mishap during installation can lead to serious injury or damage to the vehicle. Following these safety protocols is crucial for a smooth and secure installation, ensuring a safe and reliable driving experience afterward.Proper safety measures, including the use of appropriate personal protective equipment (PPE) and adherence to specific handling guidelines, are paramount during this process.

This section Artikels essential safety precautions to mitigate risks and ensure a successful installation.

Importance of Safety Equipment

Ensuring safety during installation involves the crucial use of appropriate safety equipment. This safeguards against potential hazards, minimizing the risk of accidents and injuries. Using safety glasses, gloves, and sturdy work boots, for instance, protects the eyes, hands, and feet from flying debris, sharp edges, or potential falls.

- Safety glasses protect the eyes from flying particles and debris generated during the installation process.

- Gloves prevent hand injuries from sharp edges or abrasions.

- Sturdy work boots provide ankle support, crucial for stability when working on the vehicle.

Safety Guidelines for Handling Components

Handling the accelerator components and the adaptor plate requires careful attention to prevent damage or injury. Improper handling can lead to scratches, dents, or breakage, impacting the quality of the installation.

- Components should be handled with clean hands and using soft cloths to avoid scratching or damaging the delicate surfaces.

- Use appropriate tools to avoid force that could cause damage or breakage.

- Components should be stored in a safe and dry location to prevent corrosion or other damage.

Safety Procedures for Different Installation Stages

The following table summarizes the critical safety procedures for each stage of the accelerator attachment process, highlighting the necessary equipment and key considerations.

| Stage | Safety Procedures | Equipment | Remarks |

|---|---|---|---|

| Disconnecting the Battery | Disconnect the negative terminal first, then the positive terminal. Ensure the battery is completely disconnected before working on any electrical components. | Wire cutters/strippers, safety glasses | Improper battery handling can lead to electrical shocks. |

| Removing the Old Accelerator | Use appropriate tools to avoid force that could damage the vehicle. Wear gloves to prevent cuts or scrapes. | Socket wrench set, adjustable wrench, gloves, safety glasses | Avoid rushing or applying excessive force. |

| Installing the Adaptor Plate | Ensure the adaptor plate is aligned correctly to the mounting points. Use clamps or other securing mechanisms for proper alignment. | Measuring tools, alignment tools, safety glasses | Incorrect alignment can lead to misalignment or instability. |

| Connecting the New Accelerator | Double-check all connections and ensure they are secure. Pay attention to the correct orientation of the accelerator. | Screwdrivers, wrenches, safety glasses | Improper connection can result in malfunction or damage. |

| Final Inspection | Thoroughly inspect all connections, and ensure everything is properly secured and aligned. | Safety glasses, inspection mirror | A thorough final inspection is crucial to prevent any hidden issues that may arise later. |

Variations and Special Cases

Navigating the diverse landscape of BMW models necessitates an understanding of tailored accelerator attachments. Just like a bespoke suit fits differently on each individual, the installation process isn’t a one-size-fits-all affair. Different BMW models, especially those with performance modifications, demand specific considerations for the adaptor plate and accelerator attachment. Understanding these variations ensures a seamless and safe installation, avoiding potential pitfalls and ensuring optimal performance.

BMW Model-Specific Variations

BMW’s extensive model range presents a variety of accelerator attachment configurations. The M Performance models, for instance, often feature unique throttle bodies and mounting points, necessitating specialized adaptor plates. These plates often include unique mounting points and reinforcement features to accommodate the heightened demands of performance modifications. Similarly, certain vintage models might have unique cable routing or specific hardware requirements, impacting the installation process.

A thorough understanding of the specific model’s design is paramount.

Modifications and Performance Upgrades

Performance upgrades, such as installing aftermarket intake systems or exhaust manifolds, can introduce complexities in the accelerator attachment process. These modifications might alter the engine bay’s geometry, requiring custom adaptor plates or adjustments to the accelerator cable routing. A crucial aspect is ensuring the upgraded components are compatible with the specific adaptor plate and attachment method. Careful consideration of the model’s specific modifications is essential for a successful installation.

Unusual Attachment Methods, How does bmw accelerator attach to adaptor plate

Certain BMW models, particularly those with unique or complex designs, may feature unusual accelerator attachment methods. Some models employ electric throttle systems that necessitate specific wiring and connector configurations. These systems often require meticulous attention to detail and a deep understanding of the vehicle’s electrical system. Understanding the specific electrical requirements is critical for successful installation.

Complex Attachment Cases

Complex accelerator attachment cases may arise from specific modifications, including the installation of performance chips or tuning modules. These cases demand a comprehensive understanding of the system’s interactions. These modifications can alter the engine’s characteristics and require careful consideration of the throttle response and calibration. Proper diagnostic tools and technical expertise are often necessary for accurate and reliable results.

Example: M3 Performance Upgrade

Consider an M3 undergoing a performance upgrade. The standard accelerator attachment may not be compatible with the enhanced throttle body. A custom adaptor plate with reinforced mounting points is essential. The increased horsepower necessitates a throttle body capable of handling the added load. This customized approach ensures optimal performance and longevity.

Visual Representation: How Does Bmw Accelerator Attach To Adaptor Plate

Unlocking the intricacies of the BMW accelerator attachment requires a visual roadmap. This section provides a comprehensive visual guide, allowing you to visualize the process and identify potential pitfalls before you start. Understanding the assembly’s components and their arrangement is key to a successful installation.Visual representation is not just about seeing; it’s about understanding. High-quality diagrams and illustrations, presented in various perspectives, facilitate a deeper comprehension of the accelerator attachment and adaptor plate’s anatomy.

This visual approach empowers you to grasp the subtle nuances and potential issues, making the installation process smoother and more efficient.

Detailed Descriptions of Components

The accelerator pedal and adaptor plate are the key players in this installation. A detailed understanding of each component is crucial for successful attachment. The accelerator pedal, often a sophisticated piece of engineered plastic or metal, is designed for optimal response and feel. The adaptor plate, usually a metal component, acts as the intermediary between the pedal and the car’s existing system.

Accurate identification of both components’ shapes, sizes, and features ensures correct installation.

Visual Guide for Assembly Process

Visual aids are essential for navigating the assembly process. A comprehensive visual guide, presented as a series of diagrams, will illustrate the steps in the process. Each diagram should clearly depict the alignment, positioning, and connection points of the accelerator and the adaptor plate. This visual approach minimizes the risk of misalignment and incorrect installation, which can lead to performance issues or even damage.

Use of Diagrams and Illustrations

Diagrams and illustrations serve as a critical visual guide during the installation process. They provide a clear and concise representation of the accelerator and adaptor plate components, showing their relative positions and connections. For instance, a diagram could highlight the precise location of mounting holes, ensuring the adaptor plate is firmly secured. A series of illustrations, from initial preparation to final assembly, would greatly enhance the understanding of the process.

Different Perspectives of the Attachment

To fully grasp the attachment process, multiple perspectives are essential. This allows for a comprehensive view of the accelerator and adaptor plate’s relationship with the car’s existing system. Front, side, and top-down views are critical for identifying potential interference points or misalignments. By examining the attachment from different angles, a detailed understanding of the process can be obtained.

This is critical in ensuring proper fitment and function. For example, a top-down view can highlight the alignment of mounting points, while a side view can show the relationship between the accelerator and the vehicle’s frame.

Last Recap

So, there you have it—a complete guide to attaching your BMW accelerator to the adaptor plate. Remember safety first, follow the steps precisely, and use the right tools. This guide is your go-to resource for a successful and worry-free installation. If you encounter any issues, refer to the troubleshooting section. Happy wrenching!

Questions and Answers

What are the common materials used for BMW adaptor plates?

Aluminum, steel, and sometimes composite materials are common choices, depending on the specific model and desired strength/weight ratio.

What torque specifications should I use during installation?

Always consult your BMW repair manual for the precise torque specifications for your specific model. Incorrect torque can lead to damage.

What are the symptoms of a faulty accelerator connection?

Hesitation or lack of responsiveness are common symptoms. Also, look for unusual noises or vibrations during acceleration.

Where can I find detailed diagrams for my specific BMW model?

Your BMW repair manual or the manufacturer’s website will likely have detailed diagrams and illustrations for your specific model. You can also consult online forums for specific model-related advice.