How to change blades twister lazer key cutter is a crucial skill for anyone working with this precision tool. Mastering this process ensures optimal performance and longevity of your key cutting equipment. From the initial disengagement of the old blade to the secure installation of the new one, this guide will meticulously detail every step, empowering you to handle this task with confidence and safety.

Understanding the different blade types and their specific applications is key. This guide explores the various blade materials and their performance characteristics, helping you select the right blade for the task at hand. Furthermore, we’ll address common troubleshooting steps for blade-related issues, offering solutions for a seamless key cutting experience.

Introduction to Twister Lazer Key Cutters

Hai semuanya! Twister Lazer key cutters are like the superhero tools of the key-cutting world. They use laser precision to make keys with lightning speed, which is super helpful for locksmiths and DIY enthusiasts alike. These cutters are a game changer for anyone needing a fast and accurate way to cut keys.

Operating Principles

Twister Lazer key cutters work by using a high-powered laser beam to melt and cut through metal. This laser beam is precisely controlled by a sophisticated system, ensuring clean and accurate cuts. The precise movement of the cutter head is crucial in achieving the desired key shape.

Types of Blades

The blades in Twister Lazer key cutters are typically made from high-quality, heat-resistant materials like tungsten carbide. Different blades are designed for various key types and thicknesses. These blades are replaceable, allowing for versatility and adaptability to different key cutting needs. A variety of blade shapes exist for diverse key types, enhancing the cutter’s adaptability.

Applications

Twister Lazer key cutters are widely used by locksmiths for quick key duplication. They are also a valuable tool for automotive repair shops, providing a way to make replacement keys quickly and efficiently. Do-it-yourselfers can also benefit from these cutters to create custom keys for locks or even for home use.

Comparison of Twister Lazer Key Cutter Brands

| Brand | Blade Type | Features | Price (Estimated) |

|---|---|---|---|

| Brand A | Tungsten Carbide | High precision, durable, various blade sizes available. | Rp 2,500,000 – Rp 3,000,000 |

| Brand B | Ceramic | Lightweight, fast cutting speed, good for delicate key cutting. | Rp 1,800,000 – Rp 2,200,000 |

| Brand C | Diamond | Extremely durable, ideal for high-volume key cutting. | Rp 3,500,000 – Rp 4,000,000 |

Note: Prices are estimated and may vary depending on the specific model and retailer. These estimates are based on common market pricing.

Blade Changing Procedures

Changing blades on your Twister Lazer key cutter is a piece of cake! Just follow these steps carefully, and you’ll be back to cutting keys in no time. It’s important to prioritize safety throughout the process. Proper technique prevents accidents and ensures your tool remains in top condition.

Safety Precautions

Safety is paramount when handling any sharp tools. Always ensure the key cutter is unplugged or turned off before starting any blade changing procedures. Wear appropriate safety glasses to protect your eyes from flying debris. Make sure your work area is clean and well-lit. This will help you see clearly and avoid any accidental slips or falls.

A clean workspace enhances efficiency and minimizes the risk of injuries.

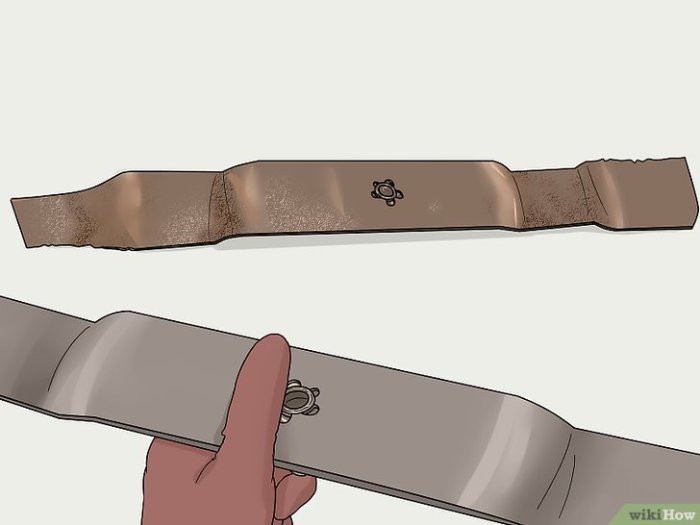

Blade Removal Steps

To remove the old blade, firmly grip the blade-changing mechanism. Ensure you have a firm hold to prevent any slippage. Apply gentle but consistent pressure to dislodge the blade from its mounting point. Avoid using excessive force, as this could damage the mechanism. Once the blade is loose, carefully slide it out of the key cutter.

Proper blade removal ensures the safety of both the user and the machine.

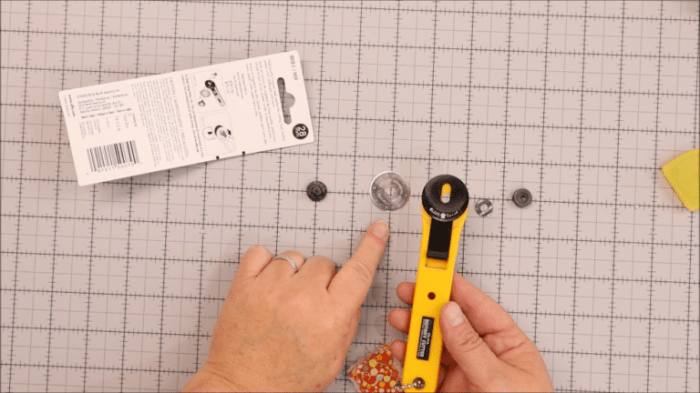

Blade Installation Steps

Before inserting the new blade, ensure it’s the correct type for your Twister Lazer key cutter. Mismatched blades can lead to improper cutting or damage to the machine. Holding the new blade correctly, align the blade’s mounting points with the key cutter’s slots. Then gently push the blade into place, making sure it’s fully seated. Avoid twisting or forcing the blade, as this could lead to damage to the machine.

Correct blade insertion guarantees optimal cutting performance and machine longevity.

Correct Hand Position and Grip

Maintaining a proper hand position and grip is essential to prevent accidents and ensure a smooth blade change. Hold the blade-changing mechanism with your dominant hand, ensuring a firm but not overly tight grip. Use your other hand to hold the new blade, positioning it correctly before insertion. This balanced grip allows for precise control during the blade change process.

Proper hand position reduces stress on your hands and prevents injury.

Visual Guide for Blade Replacement

| Step Number | Action | Image Description |

|---|---|---|

| 1 | Unplug the Twister Lazer key cutter. | The key cutter is unplugged from the power source, ensuring electrical safety. |

| 2 | Locate the blade-changing mechanism. | Identify the specific part of the key cutter responsible for blade changes. |

| 3 | Firmly grip the blade-changing mechanism. | A hand is shown holding the blade-changing mechanism firmly, demonstrating correct grip. |

| 4 | Apply gentle pressure to dislodge the old blade. | The hand applies gentle, consistent pressure to remove the old blade from its mounting point. |

| 5 | Carefully slide the old blade out of the key cutter. | The old blade is being slid out of the key cutter with caution. |

| 6 | Ensure the new blade is the correct type. | The new blade is compared to the specifications to ensure compatibility with the key cutter. |

| 7 | Align the new blade with the mounting points. | The new blade is precisely positioned in alignment with the key cutter’s mounting points. |

| 8 | Gently push the new blade into place. | The new blade is pushed into place with a gentle, steady force. |

| 9 | Verify the blade is fully seated. | The blade is confirmed to be securely seated in the key cutter. |

Blade Types and Compatibility

Hey there, key cutting enthusiasts! Today, we’re diving deep into the fascinating world of Twister Lazer key cutter blades. Understanding the different blade types and their specific uses is crucial for achieving optimal results. Just like choosing the right tool for the job, selecting the correct blade ensures a smooth and precise cut, and we’ll break down all the important details for you.

Different Blade Types

Different blade types cater to various key cutting needs. Each blade is designed with specific characteristics to excel in particular applications. From intricate designs to robust construction, the right blade will enhance your key cutting experience.

- Standard Blades: These are your workhorse blades, perfect for general-purpose key cutting. They’re versatile, handling most common key types with ease. Their balanced design provides good cutting performance without unnecessary complexity.

- Fine-tooth Blades: For those intricate and detailed key designs, fine-tooth blades are the way to go. Their razor-sharp edges and closely spaced teeth are ideal for cutting the fine lines and intricate patterns found in high-security keys. They excel at producing clean cuts and precise details.

- Heavy-duty Blades: These blades are built for durability and power. They’re designed to handle thick or challenging key materials, such as those found in automotive or high-security locks. These blades offer significant strength and stability for demanding applications.

- Specialized Blades: These blades are tailored for specific key types, like those with unusual shapes or materials. These blades have specialized geometries, often featuring specific tooth angles or edge configurations. This targeted approach provides exceptional cutting performance on these unique key designs.

Blade Material Compositions

The material composition of a blade significantly impacts its performance. Different materials offer various strengths, weaknesses, and durabilities. Choosing the right material ensures the blade maintains its edge and provides reliable cuts.

- High-carbon Steel: Known for its sharpness and durability, high-carbon steel blades maintain their cutting edge for an extended period. They excel in providing clean cuts on various key materials.

- Stainless Steel: These blades are resistant to corrosion, making them suitable for use in humid or wet environments. Their corrosion resistance is a major advantage for users in diverse climates.

- Tungsten Carbide: This extremely hard material provides exceptional wear resistance and sharpness, making it ideal for heavy-duty cutting tasks. Tungsten carbide blades are particularly well-suited for cutting extremely hard or thick materials.

Blade Comparison Table

This table summarizes the different blade types, their materials, key types they’re suitable for, and their respective pros and cons.

| Blade Type | Material | Key Types | Pros/Cons |

|---|---|---|---|

| Standard | High-carbon Steel | Most common keys | Versatile, good value, decent performance. Can be less effective on very hard or complex keys. |

| Fine-tooth | High-carbon Steel | Intricate, detailed keys | Excellent for fine details, precise cuts. Can be more fragile than standard blades. |

| Heavy-duty | High-carbon Steel or Tungsten Carbide | Thick, challenging keys | Stronger, handles tough materials. Can be more expensive and less versatile for general use. |

| Specialized | Various (depending on key type) | Unusual shapes, materials | Tailored for specific needs, excellent performance for particular key types. Might be less adaptable for general use. |

Troubleshooting Blade Issues

Hey there, key cutting enthusiasts! Facing blade problems with your Twister Lazer key cutter? Don’t fret! This section will guide you through common blade issues, their causes, and the easiest solutions. We’ll make sure you’re back to key-cutting like a pro in no time, just like our palembang friends are quick on their feet!Proper blade maintenance is key to consistent, precise key cutting.

Ignoring blade problems can lead to frustration and potentially damaged keys. Let’s dive in and tackle these issues head-on!

Common Blade-Related Problems

Understanding the potential issues with your Twister Lazer key cutter blades is crucial for effective troubleshooting. Different problems stem from various reasons, from simple user errors to more complex blade-related issues. Knowing these common issues will help you identify the root cause and apply the right solution.

Reasons for Improper Cutting, How to change blades twister lazer key cutter

Several factors can affect the cutting performance of your Twister Lazer key cutter blades. These factors can range from simple user errors to blade wear and tear. Let’s examine some of these key factors.

- Blunt Blades: A dull blade will struggle to make clean cuts, leading to uneven or jagged edges on the key. This is often due to overuse or improper sharpening techniques. A dull blade can also make the key cutting process much more difficult and frustrating.

- Incorrect Blade Type/Size: Using a blade that isn’t compatible with your key cutter model or the specific key material can result in poor cutting performance. Mismatched blades can lead to problems such as the blade bending or not cutting deeply enough. Ensure you’re using the correct blade size and type for optimal results.

- Blade Misalignment: An incorrectly positioned blade can result in uneven or inaccurate cuts. A misaligned blade will struggle to follow the key cutting design, resulting in improper key profiles. Make sure the blade is properly secured and aligned with the cutter’s guide.

- Insufficient Pressure/Force: Applying insufficient force while cutting can result in an incomplete cut, which may lead to weak or incomplete key profiles. The key cutting process may also be more challenging and time-consuming.

Diagnosing Blade Wear and Tear

Regularly inspecting your blade for signs of wear and tear is essential for maintaining optimal cutting performance. Early detection of wear can prevent further issues and save you from frustrating problems later.

- Visual Inspection: Carefully examine the blade’s cutting edge for any signs of chipping, bending, or excessive wear. A chipped blade will have a jagged edge that will affect the quality of the key cut. Bent blades may also cause inconsistencies in the cutting process.

- Feel the Blade: Run your finger along the cutting edge to feel for any roughness or irregularities. A rough or uneven edge suggests wear and tear. A smooth, sharp edge indicates a blade in good condition.

- Listen to the Cutting Process: Pay attention to the sound the blade makes during the cutting process. A grinding or scraping sound might indicate a dull blade or other problems.

Troubleshooting Table

This table provides a concise overview of common blade issues, their potential causes, and solutions.

| Problem | Possible Cause | Solution |

|---|---|---|

| Keys not cutting cleanly | Blunt blade, incorrect blade type, blade misalignment | Sharpen the blade, replace with correct blade type, re-align the blade |

| Keys not cutting deeply enough | Insufficient pressure, incorrect blade type | Increase pressure, replace with correct blade type |

| Blade bending/breaking | Incorrect blade type, excessive force, blade wear and tear | Use the correct blade type, reduce force, replace the blade |

| Grinding/scraping sound during cutting | Dull blade, misalignment, incorrect blade type | Sharpen the blade, realign the blade, use the correct blade type |

Maintaining Twister Lazer Key Cutters

Maintaining your Twister Lazer key cutter is like taking care of a precious friend. Regular upkeep ensures smooth operation, prolongs the life of your machine, and keeps those key-cutting jobs coming along smoothly. Just like a good palembang breakfast, proper maintenance is essential for a happy, productive machine!Proper maintenance isn’t just about keeping things clean; it’s about ensuring peak performance and preventing potential problems down the road.

A well-maintained Twister Lazer will reward you with precision cuts and years of reliable service.

Essential Maintenance Steps

Regular maintenance is crucial for optimal performance and longevity of your Twister Lazer key cutter. Ignoring these steps can lead to decreased efficiency and even costly repairs in the future. Think of it like keeping your favorite pair of jeans looking sharp – a little TLC goes a long way!

- Blade Inspection and Replacement: Check your blades regularly for wear and tear. A dull or damaged blade can lead to uneven cuts and potentially damage the machine. Replace blades when necessary, following the blade types and compatibility guidelines. This step is crucial to maintain accurate and precise key cuts.

- Cleaning the Cutting Area: Remove any debris or shavings from the cutting area after each use. This prevents clogging and ensures clean cuts. A clean cutting area is a happy cutting area!

- External Cleaning: Wipe down the exterior of the machine with a soft cloth and a mild cleaning solution. Avoid harsh chemicals. A clean machine looks good and functions better.

- Lubrication: Regular lubrication of moving parts is essential for smooth operation and extended machine life. Use a suitable lubricant, such as a light machine oil, specifically designed for precision instruments. This will prevent friction and keep the machine running smoothly, like a well-oiled machine.

- Checking for Alignment: Periodically check the alignment of the cutting head and blade. Misalignment can lead to inaccurate cuts. Ensure that the machine’s components are correctly aligned for consistent and accurate key cutting.

- Storing the Machine: Store the machine in a cool, dry place when not in use. This will help to prevent rust and corrosion. Protect your Twister Lazer like you would a prized possession, keeping it safe and sound in a proper storage space.

Importance of Regular Blade Maintenance

Regular blade maintenance is critical to prevent inaccurate cuts, reduce the risk of blade breakage, and maintain the precision of the Twister Lazer key cutter. A sharp blade will give you consistently better results, just like a well-honed knife will give you a better cut.

Proper Cleaning Procedures

Thorough cleaning of the cutting area and external components is essential to maintain the machine’s efficiency and appearance. Regular cleaning prevents the accumulation of debris and ensures a clean and accurate cutting process. Cleanliness is next to key cutting!

Steps for Lubricating Machine Parts

Proper lubrication of moving parts reduces friction and wear, extending the life of your Twister Lazer key cutter. A well-lubricated machine will run smoothly and quietly. Lubrication is essential for smooth operation!

- Identify the moving parts that require lubrication.

- Apply a small amount of appropriate lubricant to the identified parts.

- Wipe off any excess lubricant.

Advanced Blade Techniques

Hey, fellow key-cutting enthusiasts! Ready to level up your Twister Lazer key cutting game? This section dives into advanced blade techniques, unlocking the full potential of your tool for intricate key designs and specialized applications. Get ready to impress with these pro tips, straight from the Palembangean key-cutting gurus!

Specialized Blade Applications

Different blade types are designed for specific key types and cutting needs. Understanding these nuances allows for more precise and efficient cutting. Some blades are optimized for intricate lock patterns, while others are better suited for larger, bulkier keys. Knowing which blade to use for a particular key significantly impacts the outcome and ensures a professional finish.

Advanced Cutting Methods for Various Key Types

Mastering different cutting methods is key to handling various key types effectively. For instance, a precise, controlled cut is essential for high-security keys, while a more aggressive approach might be necessary for simpler, standard keys. Consider the key’s material and the lock’s design when selecting your approach. This is where experience and practice truly shine.

Unique Procedures and Tips for Advanced Users

Advanced users often discover techniques for optimizing blade performance and efficiency. These can involve adjusting the cutting pressure, blade angle, and even the speed of the cutting process. Experimentation and practice are crucial in refining these techniques. For instance, a slight variation in blade angle can dramatically impact the final key cut.

Table of Advanced Blade Techniques

| Technique | Application | Key Type | Steps |

|---|---|---|---|

| Precise Cutting for High-Security Keys | Creating intricate, precise cuts for complex lock patterns. | High-security keys with complex tumblers or pins. | 1. Select a fine-tooth blade. 2. Apply consistent, light pressure. 3. Maintain a steady hand and controlled speed. 4. Regularly check the cut for accuracy. |

| Aggressive Cutting for Standard Keys | Efficiently cutting through thicker materials or simpler key designs. | Standard keys with fewer tumblers. | 1. Choose a thicker, more robust blade. 2. Apply moderate to high pressure, adjusting as needed. 3. Ensure consistent blade contact. 4. Check the cut for accuracy. |

| Blade Angle Adjustment | Fine-tuning the blade’s angle for optimal cutting results. | All key types. | 1. Observe the blade’s angle relative to the key. 2. Adjust the angle slightly to achieve a clean cut. 3. Experiment to find the ideal angle for different key types. 4. Monitor the cut for any irregularities. |

| Cutting Speed Adjustment | Optimizing the cutting speed for improved precision and efficiency. | All key types. | 1. Start with a moderate speed. 2. Adjust speed based on the key material and lock design. 3. Ensure consistent speed throughout the cutting process. 4. Monitor the cut for smoothness. |

Safety Precautions

Using a Twister Lazer key cutter is a rewarding experience, but safety is paramount. Just like any tool, it’s crucial to understand the potential hazards and take the necessary precautions to avoid accidents. Following these safety measures will ensure a safe and productive experience, like a smooth-flowing wayang kulit performance.Proper handling and awareness of potential risks are essential for preventing injuries.

Neglecting safety can lead to serious consequences, from minor cuts to more severe injuries. Let’s delve into the critical safety precautions to keep you and your work safe.

Essential Safety Gear

Proper protective gear significantly reduces the risk of injury when working with a key cutter. Wearing the appropriate safety gear is a fundamental aspect of responsible tool use, much like ensuring your wayang kulit puppets are well-maintained.

- Eye Protection: Safety glasses or goggles are vital to shield your eyes from flying debris, especially when changing blades or during cutting operations. A sharp blade can cause serious eye damage if it breaks or chips, so protecting your eyes is critical.

- Gloves: Wear heavy-duty work gloves to protect your hands from cuts and abrasions. These gloves should be made of a material that provides a good grip and is resistant to blade penetration. This is crucial to prevent any unpleasant surprises during operation.

- Appropriate Clothing: Wear clothing that covers your skin, avoiding loose-fitting sleeves or clothing that could get caught in the machine. Avoid wearing jewelry that could get caught or entangled in the blade mechanism, ensuring a comfortable and secure workflow, like a well-rehearsed dance performance.

Blade Changing Procedures – Safety First

Blade changes require meticulous attention to detail. Improper blade changes are a common cause of accidents.

- Power Off: Always turn off the key cutter’s power before attempting any blade changes. This is a critical safety step, ensuring that the machine is completely inactive before any adjustments are made. This is like making sure the gamelan is silent before starting a new composition.

- Secure the Machine: Ensure the key cutter is securely fastened to a stable surface to prevent accidental movement during the blade-changing process. A secure setup is essential to prevent any unwanted surprises or accidents, just like a stable foundation for a wayang kulit performance.

- Blade Handling: Use both hands when handling blades to maintain a firm grip. Avoid twisting or forcing the blades, as this can cause them to break and result in injuries. Handle the blades with care, like precious treasures, to prevent any damage.

General Safety Precautions

Following these general safety precautions will enhance your overall safety and protect you from unforeseen hazards.

- Work in a Well-Lit Area: Ensure the workspace is well-lit to prevent any accidents due to poor visibility. This is like ensuring a clear stage for your wayang kulit performance.

- Clear the Workspace: Keep the area around the key cutter free of any obstructions or materials that could interfere with the operation or create a tripping hazard. This is important to prevent any unforeseen incidents or accidents, like a misplaced prop during a performance.

- Avoid Distractions: Concentrate on the task at hand. Avoid distractions that could lead to accidents, just as you would focus on your role in a wayang kulit performance.

- Regular Maintenance: Regularly inspect the key cutter for any signs of damage or wear and tear. Addressing potential issues promptly can prevent serious accidents. This is crucial for ensuring the longevity and safe operation of the key cutter, like maintaining a traditional craft.

Final Thoughts

In conclusion, changing blades on a Twister Lazer key cutter, while seemingly intricate, becomes straightforward with the right knowledge and guidance. This comprehensive guide provides a detailed, step-by-step approach to blade replacement, ensuring safety and efficiency. By understanding blade types, troubleshooting potential issues, and maintaining your cutter, you’ll maximize its performance and extend its lifespan. This knowledge empowers you to tackle key cutting tasks with precision and confidence.

Q&A: How To Change Blades Twister Lazer Key Cutter

What are the common blade-related problems in Twister Lazer key cutters?

Common blade-related problems include dull blades, misaligned blades, or blades that don’t cut properly. These issues can stem from improper blade selection, incorrect cutting pressure, or general wear and tear.

What safety precautions should I take when changing blades?

Always ensure the cutter is unplugged before starting any blade replacement procedure. Use appropriate protective gear, such as safety glasses and gloves. Pay close attention to the blade’s sharp edges and handle it with care.

What are the different blade types compatible with Twister Lazer key cutters?

The compatibility depends on the specific model. Consult the manufacturer’s documentation or the user manual for a list of compatible blade types. Different blade types are suited for various key materials and cutting complexities.