How to clean cast aluminum sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. Proper cleaning methods are crucial for maintaining the aesthetic appeal and longevity of cast aluminum, whether it’s kitchenware, outdoor furniture, or other applications. This guide delves into the specifics, exploring different types of cast aluminum, essential cleaning supplies, pre-cleaning procedures, cleaning methods, and post-cleaning care.

We’ll also address common issues and provide safety precautions to ensure a successful and safe cleaning process.

From understanding the diverse types of cast aluminum and their unique cleaning requirements to mastering various cleaning solutions and techniques, this guide will equip you with the knowledge and tools to effectively and safely clean your cast aluminum items. We’ll cover everything from pre-cleaning procedures to post-cleaning maintenance, ensuring your cast aluminum stays in pristine condition for years to come.

Introduction to Cast Aluminum Cleaning

Cast aluminum, a widely used alloy, possesses a unique combination of properties that make it suitable for diverse applications, from architectural elements to kitchenware. Its strength, durability, and relatively low cost have cemented its place in manufacturing. However, maintaining the pristine appearance and extended lifespan of cast aluminum requires meticulous cleaning practices. Improper methods can lead to unsightly damage, compromising the integrity and aesthetic appeal of the product.Understanding the nuances of cast aluminum’s composition, the different types available, and the potential damage from incorrect cleaning procedures is critical for preserving its value and beauty.

This comprehensive overview provides insights into the history of cast aluminum, the varied types, and the essential cleaning protocols to ensure its longevity.

Properties of Cast Aluminum Relevant to Cleaning

Cast aluminum’s composition, primarily aluminum with varying amounts of other metals like copper, magnesium, and silicon, influences its cleaning requirements. The presence of these alloying elements can affect its susceptibility to corrosion and its response to different cleaning agents. Aluminum’s inherent reactivity with certain chemicals underscores the importance of employing appropriate cleaning methods. The inherent softness of the metal compared to other materials, while aiding in its formability, also necessitates careful handling to avoid scratching or abrasion during cleaning.

Importance of Proper Cleaning Methods

Proper cleaning methods are crucial for maintaining the aesthetic appeal and extending the lifespan of cast aluminum products. Neglecting proper cleaning can lead to premature corrosion, dulling of the surface finish, and the development of unsightly blemishes. The process of cleaning cast aluminum must be approached with care and attention to detail to avoid damaging the metal’s surface.

This care ensures a longer lifespan and maintains the value of the item.

Different Types of Cast Aluminum and Their Cleaning

Various types of cast aluminum exist, each with unique characteristics that impact cleaning procedures. These differences stem from the specific alloying elements incorporated during the manufacturing process.

| Aluminum Type | Typical Applications | Cleaning Recommendations |

|---|---|---|

| 6061 | Architectural components, automotive parts, and construction | Mild detergents and water. Avoid abrasive cleaners that can scratch the surface. Neutral pH solutions are best. |

| 7075 | Aircraft components, sporting goods, and high-strength structural applications | Mild detergents and water. Use a soft cloth or sponge to avoid scratching. Avoid harsh chemicals or abrasives. |

| 3003 | Exterior building components, window frames, and roofing | Mild detergents and water. Use a soft brush or sponge. Avoid abrasive cleaners and acidic solutions. |

| 356.0 | Die castings, automotive parts, and consumer goods | Mild detergents and water. A soft-bristled brush can be used. Avoid strong acids and abrasive materials. |

Potential Damage from Improper Cleaning

Improper cleaning methods can lead to significant damage to cast aluminum. Using abrasive cleaners or harsh chemicals can cause scratches, pitting, and discoloration. Exposure to corrosive substances can accelerate the deterioration process, reducing the structural integrity and aesthetic value of the material. Incorrect cleaning practices can also cause a dulling of the surface finish, making the item look old and less appealing.

History of Cast Aluminum and Its Applications

Cast aluminum’s history traces back to the late 19th century. Early applications focused on architectural elements and decorative objects. The development of alloys and casting techniques expanded its range of applications. Its strength and durability made it a desirable material for diverse industries. Today, cast aluminum is commonly found in construction, transportation, and consumer goods, reflecting its versatility and reliability.

Essential Cleaning Supplies: How To Clean Cast Aluminum

Proper cleaning of cast aluminum requires the right tools and solutions. Improper methods can lead to damage, dulling, or premature corrosion. Choosing the correct cleaning agents and tools ensures a safe and effective cleaning process, preserving the integrity and aesthetic appeal of the aluminum.Cast aluminum, due to its inherent properties and susceptibility to oxidation, demands careful consideration of cleaning agents and tools.

The selection should account for the aluminum’s composition, the presence of any surface coatings, and the desired level of shine and protection.

Cleaning Agents for Cast Aluminum

Effective cast aluminum cleaning depends on the type of contaminant. Mild agents are suitable for everyday grime, while stronger solutions target tougher stains or corrosion. The selection of cleaning agents must be carefully considered to avoid damaging the aluminum’s surface or introducing harmful chemicals.

- Mild Detergents: These are ideal for everyday cleaning, removing dust, fingerprints, and light food residue. They are typically pH-neutral and do not contain harsh abrasives. A good example is a mild dish soap, which effectively cleans without harming the aluminum’s surface. The advantage is their safety and effectiveness on everyday dirt. The disadvantage is their limited ability to remove stubborn stains or heavy corrosion.

- Acidic Solutions: For stubborn stains or corrosion, acidic solutions can be effective. However, they should be used with caution, as they can potentially etch the aluminum surface. Vinegar or lemon juice can be used as a less potent acidic solution for certain stains. The advantage is their ability to tackle tougher contaminants, like mineral deposits. The disadvantage is their potential to damage the aluminum if not used correctly, and the need for proper safety precautions, like protective gloves and eye wear.

- Alkaline Cleaners: Some tough stains, like grease or oil, might require an alkaline cleaner. These are generally more potent than acidic solutions and should be used with caution. Specialized aluminum cleaners often contain alkaline agents, providing strong cleaning power but carrying a higher risk of damage if misused.

Cleaning Tools for Cast Aluminum

The appropriate cleaning tools significantly impact the effectiveness and safety of the process. Choosing the right tool prevents scratching or damage to the aluminum surface.

- Soft-Bristled Brushes: These are excellent for gently removing surface dirt and grime. They avoid scratching the delicate aluminum surface. Microfiber cloths or sponges are good alternatives for delicate surfaces.

- Non-Abrasive Pads: These pads are designed to clean without scratching. They are particularly useful for removing tough stains or stubborn dirt without damaging the aluminum’s finish.

- Scrubbing Brushes: These are useful for tackling heavier dirt or stubborn stains, but should be used with caution to prevent scratching. Always ensure the bristles are soft enough not to mar the aluminum’s surface.

Recommended Cleaning Agents and Tools

The selection of cleaning agents and tools depends on the specific type of aluminum and the nature of the contamination.

| Type of Stain | Recommended Cleaning Agent | Recommended Cleaning Tool |

|---|---|---|

| Everyday Dirt | Mild dish soap | Soft-bristled brush or microfiber cloth |

| Stubborn Stains | Acidic solution (vinegar or lemon juice) | Non-abrasive pad |

| Grease or Oil | Alkaline cleaner (specialized aluminum cleaner) | Scrubbing brush (with caution) |

Importance of Appropriate Cleaning Methods for Aluminum Types

Different types of cast aluminum may require specific cleaning approaches. This is due to variations in surface coatings, alloys, and manufacturing processes. Using the wrong cleaning agent or tool can lead to surface damage, compromising the integrity of the aluminum.

- Anodized Aluminum: Anodized aluminum has a protective oxide layer. Cleaning agents should be chosen carefully to avoid stripping this layer, compromising the protection. Mild detergents are typically the best choice.

- Painted Aluminum: Painted aluminum requires a gentle approach to avoid damaging the paint. Cleaning agents should be compatible with the paint type, and abrasive tools should be avoided.

Pre-Cleaning Procedures

Proper pre-cleaning is crucial for effective cast aluminum cleaning. Skipping this step can lead to ineffective cleaning, damage to the aluminum, and premature deterioration of the finish. A thorough pre-cleaning process removes loose contaminants, ensuring the cleaning solution effectively targets embedded dirt and grime.Pre-cleaning procedures are essential because they prepare the surface for subsequent cleaning steps. By removing loose debris, rust, and dirt, the cleaning solution can penetrate and effectively dissolve stubborn stains.

This proactive approach prevents scratching and ensures a more thorough and long-lasting clean.

Importance of Thorough Pre-Cleaning

Pre-cleaning significantly impacts the effectiveness and safety of the entire cleaning process. Removing loose contaminants before applying cleaning agents prevents scratching and ensures the cleaning agents can effectively reach and dissolve embedded dirt and grime. This approach significantly reduces the risk of damaging the delicate cast aluminum surface.

Step-by-Step Pre-Cleaning Guide

A methodical pre-cleaning approach is critical for optimal results. This involves a series of steps to ensure a thorough and safe removal of contaminants.

- Inspection: Carefully inspect the cast aluminum surface for visible signs of dirt, debris, rust, or other contaminants. Note the location and severity of these issues for targeted cleaning.

- Brush Cleaning: Use a soft-bristled brush or a non-abrasive scrubbing pad to remove loose dirt and debris. Avoid using abrasive materials, as they can scratch the aluminum surface.

- Water Rinse: Thoroughly rinse the surface with clean water to remove loosened dirt and debris. This step helps prevent the buildup of residue from the cleaning process.

- Rust Removal: For areas with rust, use a specialized rust remover or a paste of baking soda and water. Apply the solution, let it sit for a few minutes, and scrub gently. Rinse thoroughly with water. Avoid harsh chemicals that could damage the aluminum.

- Stubborn Stain Removal: For stubborn stains, apply a gentle cleaner like dish soap or a specialized aluminum cleaner, following the product instructions. Scrub gently with a soft-bristled brush or a non-abrasive sponge. Rinse thoroughly and dry immediately.

Methods for Removing Loose Contaminants

Efficiently removing loose dirt, debris, and rust is essential for a successful cleaning process. Various techniques can be employed to achieve this, each with varying degrees of effectiveness and safety.

- Soft-Bristled Brush: A soft-bristled brush is ideal for removing loose dirt and debris without scratching the surface. This method is effective for most surfaces.

- Vacuum Cleaning: For large areas or surfaces with significant loose debris, a vacuum cleaner can effectively remove dust and particles. Ensure the vacuum attachment is soft and non-abrasive.

- Compressed Air: Compressed air can be used to dislodge loose dirt and dust from hard-to-reach areas. Carefully direct the air stream to avoid damaging the aluminum surface.

Importance of Thorough Drying

Thoroughly drying the cast aluminum surface after pre-cleaning is crucial to prevent water spots and corrosion. Moisture left on the surface can lead to oxidation and discoloration over time. Drying ensures the aluminum maintains its pristine appearance and longevity.

Methods for Stubborn Stain Removal

Stubborn stains on cast aluminum may require more aggressive but still safe methods. Experiment with different solutions to find the most effective and least damaging approach.

- Baking Soda Paste: A paste of baking soda and water can gently lift stubborn stains without harming the aluminum. Apply the paste, let it sit for a few minutes, and gently scrub.

- Specialized Cleaners: Specialized aluminum cleaners are formulated to tackle stubborn stains. Follow the product instructions carefully for optimal results.

Comparison of Pre-Cleaning Techniques

| Pre-Cleaning Technique | Effectiveness | Safety Considerations |

|---|---|---|

| Soft-bristled Brush | Good for general dirt and debris removal | Low risk of scratching; gentle on aluminum |

| Vacuum Cleaning | Effective for large areas with loose debris | Ensure vacuum attachment is non-abrasive; avoid high suction |

| Compressed Air | Excellent for hard-to-reach areas; removes dust effectively | Carefully direct air stream; avoid damaging surface |

| Baking Soda Paste | Good for stubborn stains; gentle abrasive | May require more time; may not work for all stains |

| Specialized Cleaners | Often effective on stubborn stains; formulated for aluminum | Follow product instructions carefully; may contain harsh chemicals |

Cleaning Methods and Solutions

Cast aluminum, prized for its durability and aesthetic appeal, requires careful cleaning to maintain its pristine condition. Improper methods can lead to damage, discoloration, or premature deterioration. This section details various cleaning methods and solutions, emphasizing safety precautions and effectiveness.Different cleaning methods and solutions are suitable for cast aluminum, depending on the level of soiling and the specific type of aluminum.

Understanding these distinctions allows for targeted and effective cleaning, minimizing potential damage.

Mechanical Cleaning Methods

Mechanical cleaning methods, such as scrubbing with specialized tools, are essential for removing stubborn dirt and grime from cast aluminum. The selection of the appropriate tool depends on the severity of the soiling. Soft-bristled brushes are best for light cleaning, while stiff-bristled brushes are suitable for heavier soiling. Using abrasive materials like steel wool or scouring pads should be done cautiously, as excessive abrasion can scratch the aluminum surface.

- Soft-bristled Brush Cleaning: Gently scrub the aluminum surface with a soft-bristled brush, applying a mild cleaning solution. This method is ideal for light soiling and delicate surfaces.

- Stiff-bristled Brush Cleaning: For heavier soiling, a stiff-bristled brush can be used. Carefully scrub the affected areas, ensuring not to apply excessive pressure that could damage the aluminum. Ensure the brush is not made of abrasive materials like steel wool or metal scouring pads.

- Specialized Cleaning Tools: Specialized cleaning tools, such as aluminum-safe scrubbers or soft-bristled brushes, can be used to effectively remove stubborn stains. These tools often have a specific design for cleaning delicate surfaces without scratching the aluminum.

Chemical Cleaning Solutions

Chemical cleaning solutions can effectively tackle a wide range of stains and grime. However, the choice of solution should consider the aluminum’s condition and the type of soiling. Care must be taken when using chemical solutions, as improper application can damage the aluminum.

- Baking Soda Paste: A paste made from baking soda and water can effectively remove stubborn stains. Apply the paste to the affected area, let it sit for a few minutes, and then scrub gently with a soft brush. Rinse thoroughly with water.

- White Vinegar: A solution of white vinegar and water can be used to remove light to moderate soiling. Apply the solution to the aluminum surface and allow it to sit for a few minutes. Then, gently scrub the area with a soft-bristled brush and rinse thoroughly.

- Dish Soap Solution: A solution of dish soap and warm water can effectively remove grease and light grime. Apply the solution to the surface and scrub gently with a soft-bristled brush. Rinse thoroughly with water.

Dilution Ratios and Safety Precautions

Proper dilution ratios are crucial for effective and safe cleaning. Using too concentrated a solution can damage the aluminum surface, while a solution that is too weak may not be effective. Always follow the manufacturer’s instructions for specific cleaning solutions. Always wear appropriate personal protective equipment (PPE), such as gloves and eye protection, when using chemical cleaning solutions.

Dilution ratios for cleaning solutions should be specified by the manufacturer’s instructions. Improper dilution can damage the aluminum.

Comparison Table

| Cleaning Method | Solution Type | Effectiveness |

|---|---|---|

| Soft-bristled Brush Cleaning | Mild Cleaning Solution (e.g., dish soap) | Effective for light soiling, minimal risk of damage |

| Stiff-bristled Brush Cleaning | Baking Soda Paste or Vinegar Solution | Effective for moderate to heavy soiling, potential for damage with improper use |

| Specialized Cleaning Tools | Baking Soda Paste, Vinegar Solution | Effective for stubborn stains and delicate surfaces, minimal risk of damage with appropriate tools |

Post-Cleaning Procedures

Proper post-cleaning procedures are crucial for maintaining the integrity and longevity of cast aluminum. Neglecting these steps can lead to accelerated corrosion, dulling of the finish, and a significant reduction in the lifespan of the item. This section details the essential steps for thorough rinsing, drying, and protecting cast aluminum after cleaning.Thorough rinsing and drying, along with the application of appropriate protective coatings, are vital to preventing corrosion and preserving the aesthetic appeal of cleaned cast aluminum.

These steps, when followed meticulously, extend the life of the treated surface, minimizing the need for future costly repairs or replacements.

Rinsing and Drying

Thorough rinsing is essential to remove all traces of cleaning solution, preventing residue buildup that can lead to corrosion. Residual cleaning agents can interact with the aluminum, creating a conducive environment for oxidation and deterioration. Rinsing should be done with clean, fresh water, ensuring all traces of the cleaning solution are removed. Allowing the water to run off naturally is the best approach for removing excess moisture.

- Step 1: Immediate Rinsing: Immediately after cleaning, thoroughly rinse the cast aluminum with clean, fresh water. Use a gentle stream to avoid scratching the surface. Pay special attention to crevices and hard-to-reach areas.

- Step 2: Water Removal: Allow excess water to drain naturally. Use a clean, soft cloth to wipe away any remaining moisture. Avoid using abrasive materials or harsh scrubbing that could damage the surface.

Protecting Cast Aluminum

Protecting the cleaned surface is crucial for preventing further damage. The protective layer shields the metal from environmental elements like moisture and oxygen, delaying the onset of oxidation and corrosion. This prolongs the life of the aluminum and preserves its original appearance. The choice of protective coating will depend on the intended use and desired aesthetic outcome.

- Step 3: Drying: Complete the drying process, ensuring the surface is completely free of moisture. Use a clean, lint-free cloth to dry thoroughly, taking care not to scratch the surface.

- Step 4: Application of Protective Coating: Select a protective coating suitable for cast aluminum, considering factors such as the environment it will be exposed to and the desired aesthetic outcome. Common choices include clear lacquers, paints, or waxes.

Applying Protective Finishes

Proper application of protective finishes ensures a long-lasting barrier against corrosion. Follow the manufacturer’s instructions for each specific product. Uneven application or improper drying can lead to defects and reduced effectiveness of the protective coating.

- Step 5: Preparation for Coating: Ensure the surface is completely dry and free of any debris, dust, or dirt. Remove any remaining traces of cleaning solution or contaminants that could interfere with the adherence of the protective coating.

- Step 6: Applying Clear Lacquer: Thin the lacquer according to the manufacturer’s instructions. Apply a thin, even coat using a brush or spray gun. Allow the first coat to dry completely before applying subsequent coats. Multiple thin coats are better than one thick coat.

- Step 7: Applying Paint: Select a paint suitable for outdoor use or indoor use, depending on the environment. Prepare the surface as instructed, and apply the paint in thin coats, allowing each coat to dry before applying the next. For best results, use a high-quality paint designed for aluminum.

- Step 8: Applying Wax: Apply a coat of wax to create a protective barrier against moisture and UV rays. Follow the manufacturer’s instructions carefully for the specific wax product used. Regular reapplication is necessary to maintain the protective layer.

Troubleshooting and Common Issues

Cast aluminum, while durable, can be susceptible to damage during cleaning. Understanding potential problems and their solutions is crucial for maintaining its aesthetic appeal and structural integrity. Improper cleaning techniques or the use of unsuitable chemicals can lead to discoloration, scratches, or even weakening of the metal. This section details common issues and provides practical solutions.Careful attention to pre-cleaning procedures, the selection of appropriate cleaning agents, and the application of proper techniques can significantly reduce the risk of these issues.

Thorough rinsing and drying are equally important steps in preventing further problems.

Identifying Potential Problems, How to clean cast aluminum

Issues can range from minor discoloration to more significant damage. Recognizing these problems early allows for timely intervention and prevents further deterioration. Careful observation is key in detecting any abnormalities. For instance, a persistent haze or dulling of the surface might indicate a need for a different cleaning method.

Solutions for Discoloration and Damage

Several factors can cause discoloration, from residual cleaning agents to improper rinsing. Identifying the root cause is vital to implementing the correct solution. For instance, a whitish residue might indicate an over-application of a particular cleaning agent. Using a mild abrasive cleaner or a gentle scrub might remove the discoloration. Alternatively, a stronger cleaning agent may be required for more stubborn stains.

Dealing with Stubborn Stains and Marks

Stubborn stains or marks often require a more targeted approach. A simple solution might not suffice, and specialized cleaning agents may be necessary. For example, if the stain is due to food residue or other organic materials, a specialized degreaser or a mixture of baking soda and water may be effective. Experimenting with different cleaning methods and agents is crucial to achieving the desired outcome.

Preventing Discoloration or Damage

Avoiding damage is always preferable to repairing it. Using appropriate cleaning solutions, avoiding harsh abrasives, and ensuring proper rinsing and drying are crucial preventative measures. For instance, avoiding using abrasive sponges or steel wool on the surface can significantly reduce the risk of scratches.

Table of Common Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Discoloration (haze, dullness) | Residual cleaning agent, improper rinsing | Use a mild abrasive cleaner or a gentle scrub. Rinse thoroughly. Consider a different cleaning method if the issue persists. |

| Scratches | Use of abrasive materials (steel wool, scouring pads) during cleaning | Avoid using abrasive materials. Use soft cloths or non-abrasive cleaning tools. |

| White residue | Over-application of cleaning agent, improper rinsing | Reduce the amount of cleaning agent used. Rinse thoroughly and ensure complete removal of the residue. |

| Stubborn stains (food, grease) | Organic residue | Use specialized degreasers or a mixture of baking soda and water. Consider using a paste of baking soda and a small amount of dish soap. |

Specific Applications and Cleaning Considerations

Cast aluminum, a versatile material, finds application in diverse areas, from the kitchen to outdoor living spaces. Proper cleaning methods are crucial for maintaining its aesthetic appeal and longevity in these various settings. Different applications necessitate specific approaches to avoid damage and ensure optimal results.

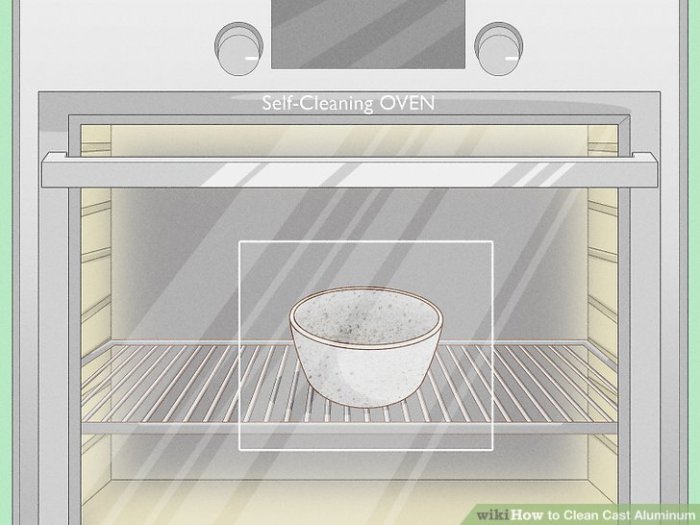

Cleaning Cast Aluminum Cookware

Cast aluminum cookware, prized for its excellent heat distribution, requires careful handling to prevent damage and maintain its effectiveness. A crucial aspect is preventing corrosion, which can diminish the cooking surface’s quality. Aggressive scrubbing or harsh chemicals should be avoided. Mild detergents and gentle scrubbing techniques are ideal.

Cleaning cast aluminum cookware safely and effectively involves a two-pronged approach: meticulous pre-cleaning to remove any stuck-on food particles and a subsequent cleaning procedure using mild, non-abrasive solutions. Avoid scouring pads and abrasive cleaners that can scratch the surface.

Specific instructions include using warm, soapy water, a soft sponge or cloth, and a non-abrasive cleaner. Rinse thoroughly and dry immediately to prevent water spots and rust. For stubborn residue, a paste of baking soda and water can be applied gently. Ensure the cookware is completely dry after cleaning to prevent water damage and corrosion.

Cleaning Cast Aluminum Outdoor Furniture

Outdoor cast aluminum furniture faces unique challenges, including exposure to harsh weather conditions and accumulated dirt. These factors require specialized cleaning protocols. The goal is to maintain the furniture’s pristine appearance and structural integrity.

Outdoor cast aluminum furniture necessitates a gentle cleaning regimen, avoiding harsh chemicals and abrasive materials that could damage the finish.

Regular cleaning with mild soap and water is essential. For stubborn stains, a mixture of mild dish soap and warm water, applied with a soft cloth, can be effective. Thorough rinsing and drying are paramount to prevent water spots and corrosion. Periodic application of a sealant can protect the finish and enhance its longevity.

Cleaning Cast Aluminum Kitchenware

Cast aluminum kitchenware, including trays, bowls, and pans, often encounters food particles and spills. Efficient cleaning techniques are necessary to prevent residue buildup and ensure hygienic conditions.

Cleaning cast aluminum kitchenware involves maintaining a consistent cleaning routine to prevent stubborn stains and maintain the cookware’s integrity.

Mild dish soap and warm water are usually sufficient for daily cleaning. For tougher stains, a paste of baking soda and water, applied gently, can be used. Rinse thoroughly and dry immediately to avoid any damage. Regular cleaning prevents build-up and maintains the kitchenware’s hygienic conditions. Always follow the manufacturer’s instructions for specific cleaning recommendations.

Safety Precautions

Proper cast aluminum cleaning demands meticulous attention to safety. Neglecting safety protocols can lead to severe health risks, from mild skin irritation to more serious chemical burns. Adherence to these precautions is crucial for a safe and effective cleaning process.Careful consideration of safety measures throughout the cleaning process is paramount. Using appropriate protective gear, selecting the correct cleaning agents, and understanding potential hazards associated with improper techniques are essential to avoid accidents.

This section details critical safety protocols for handling cleaning chemicals and tools.

Importance of Protective Gear

Safety begins with proper personal protective equipment (PPE). Using gloves, eye protection, and respirators is critical when working with cleaning solutions. Gloves prevent skin contact with harsh chemicals, while eye protection safeguards against splashes or fumes. Respirators are necessary for handling cleaning agents that release volatile organic compounds (VOCs) or particulates, potentially causing respiratory irritation or long-term health issues.

Always prioritize wearing appropriate PPE, especially when working with concentrated solutions or strong abrasives.

Handling Cleaning Solutions

Cleaning solutions, even seemingly mild ones, can cause significant harm if not handled cautiously. Always dilute cleaning solutions according to manufacturer instructions. Improper dilution can lead to increased chemical reactivity and potential burns or other injuries. Ensure the area is well-ventilated when handling any cleaning solution, especially those with strong odors. Cleaning solutions should be stored in designated containers in a cool, dry place, away from heat sources or open flames.

Always label containers clearly with the contents and safety precautions.

Potential Hazards of Improper Cleaning Agents

Using inappropriate cleaning agents can pose significant hazards. Acidic solutions, for example, can severely damage aluminum, leading to pitting or corrosion. Using abrasive cleaners on aluminum can also scratch or etch the surface, compromising its structural integrity. Carefully review the material safety data sheets (MSDS) for each cleaning agent to understand its specific properties and potential hazards.

This ensures proper handling and application techniques to prevent damage to the aluminum and protect the user.

Specific Safety Guidelines for Handling Cleaning Chemicals and Tools

Safety guidelines for handling cleaning chemicals and tools should be strictly adhered to. Avoid mixing different cleaning solutions without consulting the MSDS or a qualified professional. Some chemical reactions can produce harmful fumes or cause immediate burns. If a chemical spill occurs, follow the spill response procedures Artikeld in the MSDS. Use appropriate tools for the task.

Employing improper tools, such as using a metal scraper on a delicate aluminum surface, can cause unwanted damage. Always inspect cleaning tools for any damage or wear before use.

Safety Tips for Cleaning Cast Aluminum

- Always wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator if necessary.

- Work in a well-ventilated area, preferably outdoors or with adequate ventilation.

- Read and understand the Material Safety Data Sheet (MSDS) for all cleaning solutions before use.

- Always dilute cleaning solutions according to the manufacturer’s instructions.

- Never mix different cleaning solutions without professional guidance.

- Store cleaning chemicals in a cool, dry place, away from heat sources and open flames.

- Dispose of used cleaning solutions and materials properly according to local regulations.

- If any chemical contact with skin or eyes occurs, immediately flush the affected area with water for at least 15 minutes and seek medical attention.

- Never use abrasive cleaners on cast aluminum unless specifically recommended for the type of aluminum.

Closing Summary

In conclusion, cleaning cast aluminum effectively involves a multi-faceted approach that considers its specific type, the nature of the soiling, and appropriate cleaning methods. This guide provides a comprehensive framework for maintaining the beauty and functionality of your cast aluminum items. Remember to prioritize safety, choose the right cleaning agents, and follow the step-by-step procedures Artikeld. By adhering to these guidelines, you can ensure your cast aluminum remains in excellent condition, resisting damage and maintaining its attractive appearance.

Top FAQs

Q: What is the best cleaning solution for cast aluminum?

A: There’s no single “best” solution. The ideal cleaning agent depends on the type of soiling and the specific aluminum alloy. Mild dish soap and warm water often suffice for everyday cleaning, while more stubborn stains might require a specialized cleaner or a gentle abrasive. Always test any cleaning agent on an inconspicuous area first.

Q: Can I use steel wool to clean cast aluminum?

A: While steel wool can remove stubborn stains, it can also scratch the surface of cast aluminum. Using a gentler abrasive, such as a soft-bristled brush or a non-abrasive scouring pad, is often a better choice.

Q: How do I remove baked-on food from cast aluminum cookware?

A: For baked-on food, a paste of baking soda and water can be effective. Apply the paste, let it sit for a while, and then scrub gently with a soft brush. If the stain persists, you can try a mixture of vinegar and water, but be mindful of any potential discoloration.

Q: What are the potential risks of improper cast aluminum cleaning?

A: Improper cleaning methods, such as using harsh abrasives or strong chemicals, can lead to surface scratches, discoloration, or even damage to the metal’s structural integrity. Always choose cleaning agents and methods appropriate for cast aluminum.