How to compare a single bit in OMRON? This guide dives deep into understanding and comparing single bits within OMRON PLC programming. We’ll explore different methods for comparing bits, from simple comparisons to more complex scenarios involving ladder logic and structured text (ST). Mastering this crucial skill is essential for creating efficient and reliable PLC programs.

OMRON PLCs use bits to represent on/off states, and comparing these bits is fundamental to logic control. Knowing how to compare them lets you create programs that respond to various conditions and trigger actions accordingly. This guide covers everything from basic comparisons to advanced techniques, making it a comprehensive resource for anyone working with OMRON PLCs.

Introduction to OMRON Bits

A single bit in OMRON PLC programming is the fundamental unit of digital information. It represents a binary value, either 0 or 1, which corresponds to OFF or ON states, respectively. These simple states are the building blocks for more complex logic and control within the PLC.Understanding how bits function is crucial for designing effective and reliable automation systems.

They form the basis for controlling actuators, monitoring sensors, and implementing various control algorithms within an OMRON PLC program.

Bit Data Types

Bits in OMRON PLCs are associated with different data types, each serving a specific purpose within the program. This variety allows for efficient management of various control signals and system states. Common bit data types include inputs, outputs, and internal memory bits.

Bit Usage in PLC Programs

Bits are versatile components in PLC programming. They can be used to represent a wide range of conditions and actions. For example, a bit can signify whether a machine is running, a sensor is activated, or a specific valve is open. These binary states enable the PLC to make decisions and execute instructions based on the current status of the system.

- Input Bits: These bits represent signals coming from external devices, such as sensors or switches. They provide the PLC with information about the current state of the machine or process.

- Output Bits: These bits control external devices, such as actuators, motors, or valves. The PLC uses output bits to command actions based on the logic programmed within the program.

- Memory Bits: These bits are used for internal storage and temporary data within the PLC. They are crucial for storing intermediate results, flags, and status information during program execution.

Common Applications

Bits are extensively used in a multitude of applications. Their simple binary nature makes them ideal for controlling various aspects of a manufacturing process. Some common applications include:

- Machine Control: Bits are used to control the start and stop of machines, monitor the status of different components, and implement safety mechanisms.

- Process Control: Bits are used to monitor and control the various stages of a process, ensuring precise execution of tasks and maintaining desired parameters.

- Sequential Operations: Bits are essential in controlling the sequence of operations in a system, ensuring the correct order of events is followed.

Bit Type Comparison

The table below summarizes the functions of different bit types within an OMRON PLC program.

| Bit Type | Function |

|---|---|

| Input Bit | Represents external signals; provides information about the system’s state. |

| Output Bit | Controls external devices; commands actions based on the program’s logic. |

| Memory Bit | Stores intermediate results, flags, and status information; used for internal calculations and decision-making. |

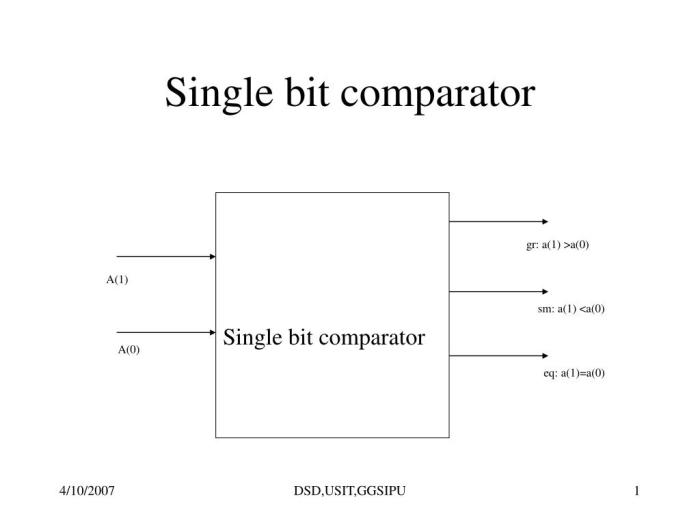

Comparing a Single Bit

Comparing bits is fundamental in OMRON PLC programming. It allows you to make decisions based on the state of individual bits, enabling complex control logic. This section details various methods for comparing single bits, crucial for creating sophisticated automation systems.Comparing a single bit to another bit, a constant, or a value is straightforward using comparison operators and logical operations.

Understanding these techniques empowers you to create precise and efficient control programs.

Comparison Operators

Comparison operators in OMRON ladder logic, like = (equal), != (not equal), > (greater than), and < (less than), are used to evaluate the state of a bit. These operators are directly integrated into the ladder logic, enabling conditional branching and execution of instructions based on the bit's value.

Example: If bit B1 is equal to 1, then turn on output O1.

Using AND, OR, and XOR

These logical operators are essential for comparing multiple bits simultaneously. The AND operator checks if

- all* bits in the operation are true, while the OR operator checks if

- at least one* bit is true. The XOR operator returns true only if

- one* of the bits is true.

- The AND operator combines multiple conditions, ensuring that all conditions are met before executing a command. For instance, you might need both bit A and bit B to be true to activate a specific output.

- The OR operator is useful for handling situations where either of several conditions can trigger an action. For example, an alarm could activate if either sensor A or sensor B detects a fault.

- The XOR operator is used to compare two bits for differences, returning true only if one bit is true and the other is false. This is particularly helpful in situations where you want to respond to a change in the status of a bit.

MOV Instruction in Bit Comparison, How to compare a single bit in omron

The MOV (move) instruction in OMRON ladder logic can be employed to copy the value of a bit to another location. This allows for the temporary storage of a bit’s state for subsequent comparison or use in complex calculations.

Example: Copy the state of bit A to bit B.

Comparison Results Table

This table illustrates possible outcomes of comparing a bit with a constant or another bit using various operators.

| Bit 1 | Bit 2 | Operator | Result |

|---|---|---|---|

| 0 | 0 | = | TRUE |

| 0 | 0 | != | FALSE |

| 0 | 1 | = | FALSE |

| 0 | 1 | != | TRUE |

| 1 | 0 | > | TRUE |

| 1 | 1 | < | FALSE |

| 1 | 1 | = | TRUE |

| 1 | 1 | != | FALSE |

Bit Comparison in Ladder Logic

Comparing bits in OMRON ladder logic is a fundamental operation. It allows you to create programs that react dynamically to various conditions, making your control systems more responsive and sophisticated. This section delves into the techniques for comparing bits and utilizing the results to drive actions in your automation processes.Ladder logic, the visual programming language used in OMRON PLCs, excels at representing logical relationships between inputs and outputs.

The comparison of bits, whether constants or other bits, forms the basis for creating conditional actions. This empowers the automation system to make decisions based on the current state of the system, enhancing its adaptability.

Comparing a Bit to a Constant Value

This involves checking if a specific bit’s state matches a predefined value. For example, you might want to activate an output only when a particular input bit is true. In ladder logic, this comparison is represented by a specific instruction.A common example is checking if an input bit representing a ‘Start’ button is pressed. The ladder logic instruction would compare this input bit to the logical value ‘1’ (true).

If the bit is true, the corresponding output is activated.

Comparing a Bit to Another Bit

Directly comparing one bit to another allows more complex logic. This is often used in situations where multiple conditions must be met. For example, an output might be activated only if two different input bits are both true.This comparison is implemented using the same comparison logic as with a constant, but instead of a constant value, you reference another bit.

The ladder logic instruction visually connects the two bits for comparison.

Using Timers and Counters with Bit Comparisons

Timers and counters provide timing and counting capabilities in ladder logic. They can be combined with bit comparisons to create more sophisticated automation sequences.For instance, a timer could be used to monitor the duration of an operation, and a bit comparison could determine if the operation duration has exceeded a specific threshold. The comparison result dictates the subsequent actions, such as activating an alarm or resetting a process.

The output would be dependent on the bit comparison, triggering actions based on the timing criteria.

Conditional Actions Based on Comparison Results

The results of bit comparisons directly influence the actions performed by the ladder logic program. This is a core concept in automation, enabling conditional responses to various system states.For example, if a sensor bit indicates a fault condition, a comparison in ladder logic would trigger the activation of an alarm output or the initiation of a corrective action. Conditional outputs are crucial for adapting automation processes to real-time situations.

Toggling an Output Bit Based on an Input Bit

A simple yet effective use of bit comparisons is toggling an output bit when a specific input bit is true. This is commonly used for control applications where an output needs to switch states in response to an input.This example creates a program that toggles an output bit whenever an input bit changes its state from true to false or false to true.

This is visually represented by a ladder logic program that checks the input bit and, based on its state, toggles the output bit accordingly.

Bit Comparison in Structured Text (ST)

Structured Text (ST) offers a powerful alternative to Ladder Logic for implementing complex logic, including bit comparisons. It provides a textual, high-level programming approach, making it easier to understand and maintain intricate control logic. This approach proves beneficial when dealing with intricate sequences and conditions that might be cumbersome to manage within Ladder Logic.Bit comparisons in ST are fundamental for building sophisticated control systems.

They allow programmers to examine the state of bits (ON or OFF) and make decisions based on those states. This flexibility allows for precise control over the system’s operation.

ST Example for Comparing a Single Bit

A simple ST example demonstrates comparing a bit ‘InputBit’ with another bit ‘CompareBit’. The code determines if ‘InputBit’ is equal to ‘CompareBit’.“`IF InputBit = CompareBit THEN OutputBit := TRUE;ELSE OutputBit := FALSE;END_IF;“`This code efficiently checks if both bits hold the same state and sets the ‘OutputBit’ accordingly.

Syntax and Usage of Comparison Operators in ST

ST uses standard comparison operators familiar from other programming languages. These operators evaluate expressions and produce Boolean results.

- Equality (=): Checks if two operands are equal.

- Inequality (<> or #): Checks if two operands are not equal.

- Greater than (>): Checks if the left operand is greater than the right operand.

- Less than (<): Checks if the left operand is less than the right operand.

- Greater than or equal to (>=): Checks if the left operand is greater than or equal to the right operand.

- Less than or equal to (<=): Checks if the left operand is less than or equal to the right operand.

These operators are fundamental for constructing complex logic within ST programs.

Comparison in Ladder Logic versus Structured Text

Ladder Logic excels at visualizing the control flow through the use of graphical elements. Structured Text, however, provides a more structured and textual approach, enabling more complex operations.

- Ladder Logic focuses on a step-by-step execution flow represented graphically, often suitable for simple logic.

- Structured Text allows for more intricate logic using conditional statements, loops, and other programming constructs, suited for more advanced systems.

Using Bit Comparison in ST for Complex Logic Operations

Bit comparisons in ST are not limited to simple equality checks. They form the building blocks for complex control logic, such as cascading conditions and multi-step processes.

ST Program Checking Multiple Conditions Using Bit Comparisons

A more sophisticated example demonstrates how multiple conditions can be checked and combined using bit comparisons.“`STIF (InputBit1 = TRUE) AND (InputBit2 = FALSE) THEN OutputBit1 := TRUE; OutputBit2 := FALSE;ELSIF (InputBit1 = FALSE) AND (InputBit3 = TRUE) THEN OutputBit1 := FALSE; OutputBit2 := TRUE;ELSE OutputBit1 := FALSE; OutputBit2 := FALSE;END_IF;“`This program illustrates the use of multiple conditions, combining bit comparisons with logical AND operations.

The outcome depends on the state of several input bits. This example shows how bit comparisons can drive complex logic decisions within a structured text program.

Error Handling and Troubleshooting

Accurately comparing bits in OMRON PLC programs is crucial for reliable automation. Errors in bit comparisons can lead to unexpected system behavior, production delays, or even safety hazards. Understanding potential pitfalls and troubleshooting techniques will enhance the robustness of your ladder logic.

Potential Errors in Bit Comparisons

Incorrect bit assignments, mismatched data types, and timing issues are common pitfalls in bit comparisons. A crucial aspect is ensuring the bits being compared are in the expected state at the precise moment of the comparison. If the bit is changing, or if there are issues with the timing of the comparison process, unexpected results are likely.

Common Causes of Comparison Errors

Several factors can cause errors in bit comparisons within OMRON PLC programs. Incorrectly wired inputs or outputs can lead to faulty bit states. Timing conflicts, especially in complex programs with multiple tasks, can cause discrepancies in the values being compared. Logic errors in the comparison statements, such as incorrect operators or misplaced brackets, can produce erroneous results.

A less common, but important factor, is the interaction of different scan cycles and the order in which operations are executed. A subtle logic error in a related part of the program might be affecting the outcome of a comparison.

Troubleshooting Steps for Bit Comparison Issues

Thorough debugging is vital when confronting bit comparison problems. First, verify the correct assignment of input/output bits to variables. Next, analyze the timing of events related to the comparison. If timing conflicts are suspected, introduce delays or use specialized timing instructions to synchronize operations. Check the PLC program for any logic errors in the comparison statements.

Pay close attention to data types and ensure that the operands are of the expected format. Finally, consider the potential influence of other parts of the program on the comparison. This may involve inspecting related program sections to isolate the root cause of the error.

Examples of Error Messages

Error messages related to bit comparisons in OMRON PLCs may vary depending on the specific PLC model and the nature of the error. However, typical messages might include “Illegal operation,” “Data type mismatch,” or “Timing error.” Other messages might be less specific, and it is often crucial to examine the program’s context to understand the root cause of the message.

Best Practices for Robust Bit Comparison Logic

Writing robust bit comparison logic involves several key practices. First, ensure clear and concise variable naming conventions to avoid confusion. Second, use descriptive comments to explain the purpose and logic behind each comparison statement. Third, employ appropriate error handling routines to catch unexpected situations and prevent critical failures. Using structured programming techniques, such as structured text (ST) blocks, can improve readability and reduce errors.

Finally, thoroughly test the comparison logic under various conditions, including edge cases, to identify and fix any potential problems.

Advanced Bit Comparison Techniques

Taking bit comparisons to the next level allows for more sophisticated control and communication within your OMRON program. This section delves into strategies for comparing bits across different tasks, optimizing performance, and using bit flags for complex logic.Advanced bit comparisons are crucial for managing intricate processes. By effectively using flags and synchronization, your automation system becomes more resilient and adaptable to changing conditions.

Inter-Task Bit Comparisons

Effective communication between different tasks in an OMRON program often hinges on comparing specific bits. These bits act as signals or flags, relaying information from one section of the program to another.Careful planning is vital. A bit set in one task must be reliably recognized and acted upon by another. Consider the timing and sequence of operations, ensuring that the bits are updated and read correctly.

Bit Flags for Comparison Results

Using bit flags to store comparison results provides a structured way to manage outcomes. Flags, by nature, are single-bit variables. This allows for concise representation of ‘true’ or ‘false’ outcomes.For example, a flag can indicate whether a specific process has completed successfully. The flag can be readily checked by other tasks in the program. This structured approach improves readability and maintainability.

Bit Comparisons for Communication Protocols

Bit comparisons are essential in communication protocols, facilitating reliable data exchange between different devices or sections of a program.This can involve verifying data integrity, acknowledging messages, and synchronizing communication. A bit set in one device signifies successful data transmission, prompting the receiving device to act accordingly. Consider the importance of clear, defined bit patterns in communication protocols for unambiguous data exchange.

Complex Bit Comparisons for Advanced Applications

Real-world applications often demand complex bit comparisons. These situations involve multiple conditions, nested comparisons, and intricate sequences.A good example might be controlling a robotic arm. A specific sequence of bits must be met before the arm can move to the next position. This sequence could involve checking sensors, confirming appropriate input data, and ensuring previous operations have completed without error.

Optimizing Bit Comparison for Performance

Optimization is key to ensuring efficient execution in OMRON programs. Unnecessary comparisons can significantly impact program performance.Clever use of data structures, combined with concise bit comparisons, can significantly improve the program’s response time. Consider whether multiple bits can be compared in a single operation. Avoid redundant checks to maintain program efficiency.

Illustrative Examples: How To Compare A Single Bit In Omron

Bit comparison in OMRON PLCs is a fundamental skill. Understanding how to compare bits, and subsequently, how to use these comparisons to control processes, is key to creating effective and reliable automation systems. These examples illustrate the practical application of bit comparison techniques.Simple scenarios demonstrate the power of bit comparison. More complex examples show how multiple comparisons can create intricate logic and automation.

Real-world applications highlight the practical use of these techniques in various industries.

Simple Example: Light Control

This example demonstrates turning a light on or off based on a sensor. A proximity sensor (bit 0) detects the presence of an object. If the object is detected, the light (bit 1) should turn on. Otherwise, it should turn off.

- The sensor bit (0) is read.

- A comparison is performed: If bit 0 is TRUE (object detected), then set bit 1 to TRUE (light on).

- Otherwise, set bit 1 to FALSE (light off).

This simple example illustrates a basic bit comparison for a straightforward automation task.

Complex Example: Machine Control

This example involves a more complex machine control system with multiple sensor inputs. A machine has three sensors (Sensor A, Sensor B, Sensor C – bits 2, 3, 4 respectively). The machine should only start if all three sensors are activated.

- Sensor A (bit 2), Sensor B (bit 3), and Sensor C (bit 4) are read.

- A logical AND operation is performed on the three sensor bits. If all three bits are TRUE, the machine start bit (bit 5) is set to TRUE.

- Otherwise, the machine start bit is set to FALSE.

- Additional actions can be added based on other conditions (e.g., turning on a motor, or activating a safety system).

This shows how multiple bit comparisons can be combined for more sophisticated control.

Real-World Application: Manufacturing Process

In a manufacturing process, a conveyor belt (controlled by bit 6) moves parts. A quality control sensor (bit 7) checks for defects. If a defect is detected, the conveyor belt must stop (bit 6 set to FALSE) and an alarm (bit 8) must be triggered.

- The quality control sensor (bit 7) is read.

- If bit 7 is TRUE (defect detected), set bit 6 to FALSE (stop conveyor) and bit 8 to TRUE (trigger alarm).

- If bit 7 is FALSE (no defect), maintain the current state of the conveyor belt (bit 6).

This manufacturing example showcases the practical application of bit comparison in controlling a critical process step, ensuring product quality.

Outcome Summary

In conclusion, comparing bits in OMRON PLCs is a crucial programming skill. This guide has provided a detailed overview of various comparison methods, from basic ladder logic to structured text. Understanding these techniques empowers you to create robust and efficient control systems. Remember to thoroughly test your programs and address potential errors for optimal results.

Expert Answers

What are the different data types associated with a bit in OMRON?

OMRON bits are typically binary, representing either 0 or 1. While not a formal data type in the same way as integers or strings, bits are used in input/output, memory, and internal use within a program.

How do I compare a bit to a constant in ladder logic?

Use comparison operators like =, !=, >, or < in your ladder logic. For instance, if you want to check if an input bit (Input 1) is equal to 1, you would use a comparison rung with the = operator.

What are common errors when comparing bits in OMRON?

Common errors include incorrect wiring, wrong comparison operators, and overlooking edge triggers. Carefully review your code for accuracy and ensure proper data handling.