How to deepen a picture frame rabbet depth unveils the secrets to crafting picture frames with enhanced depth and aesthetic appeal. This comprehensive guide explores the nuances of rabbet depth, from measuring and marking to selecting the right tools and techniques.

Understanding the ideal rabbet depth for various picture sizes and frame styles is crucial for achieving a balanced and visually appealing result. This guide will walk you through the process, highlighting key considerations and potential pitfalls.

Understanding Rabbet Depth Variations

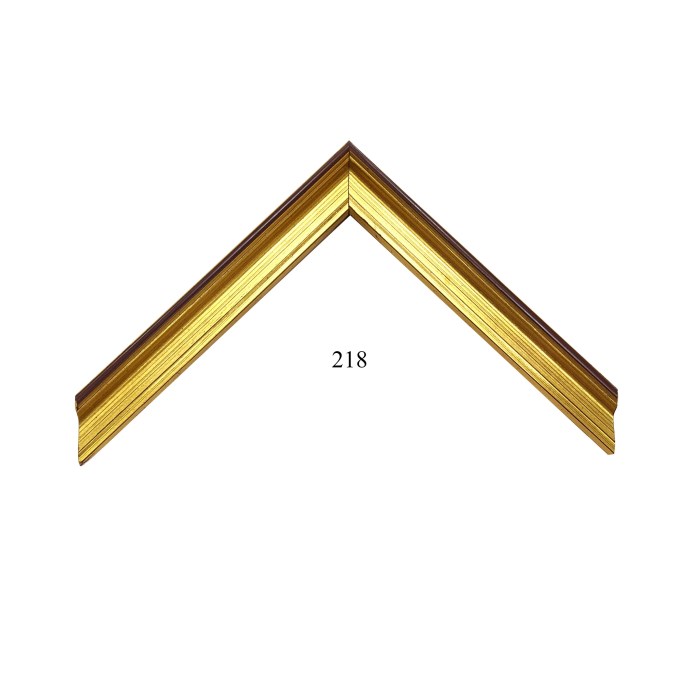

Picture frame rabbets, those often-overlooked grooves, play a crucial role in the frame’s overall aesthetic and structural integrity. The depth of the rabbet, the space between the frame’s inner and outer edges, directly influences how the picture sits within the frame and the frame’s visual impact. Different rabbet depths are chosen based on the picture’s size, the desired frame style, and the overall aesthetic goal.Understanding these nuances allows for the creation of picture frames that not only showcase the artwork but also enhance its presentation.

A well-considered rabbet depth contributes to the frame’s stability and visual harmony, complementing the picture and the surrounding environment.

Rabbet Depth and Picture Size

Choosing the appropriate rabbet depth is crucial for a visually balanced and well-proportioned picture frame. The depth needs to accommodate the picture’s thickness without sacrificing the frame’s aesthetic appeal. A deeper rabbet is better suited for thicker pictures or frames with a more substantial profile.

Ideal Rabbet Depths for Different Picture Sizes and Frame Styles

The ideal rabbet depth varies depending on the picture’s dimensions and the frame style. A small picture within a delicate frame may require a shallower rabbet than a large, heavy print in a bolder frame style. Consider the picture’s thickness as well.

- For small pictures (under 8 inches wide), shallower rabbets (1/8 inch to 1/4 inch) create a lighter, more delicate look, particularly in frames with elaborate details. This approach works well with ornate, antique-style frames or those designed to showcase delicate prints.

- Medium-sized pictures (8 to 16 inches wide) typically benefit from rabbets between 1/4 inch and 3/8 inch. These depths offer a good balance between visual impact and picture support. Common styles for this range include traditional, classic, and contemporary designs.

- Larger pictures (over 16 inches wide) often require deeper rabbets (3/8 inch to 1/2 inch or more). Deeper rabbets offer more space for thicker pictures and can create a bolder, more substantial presentation. This is especially true for artwork with a heavy or unusual support structure.

Impact of Rabbet Depth on Aesthetic

A shallow rabbet creates a subtle, almost minimalist effect, emphasizing the picture’s subject matter. A deeper rabbet can create a more substantial, almost sculptural, appearance, drawing attention to the frame itself. The choice of rabbet depth can thus significantly alter the perceived weight and character of the entire presentation. Consider the overall style of the artwork and frame when deciding on the depth of the rabbet.

Relationship Between Picture Width/Height and Recommended Rabbet Depths

The table below provides a general guideline for choosing rabbet depths based on picture width and height. Keep in mind that these are guidelines, and adjustments may be necessary depending on the specific picture and frame design. For example, a very thick print might require a slightly deeper rabbet than indicated, regardless of its size.

| Picture Width/Height | Recommended Rabbet Depth | Frame Style Considerations |

|---|---|---|

| Under 8 inches | 1/8″

|

Delicate, ornate, antique |

| 8-16 inches | 1/4″

|

Traditional, classic, contemporary |

| Over 16 inches | 3/8″

|

Bold, substantial, modern |

Measuring and Marking for Accurate Rabbets: How To Deepen A Picture Frame Rabbet Depth

Precision in measuring and marking is crucial for achieving a flawless rabbet. A slightly off measurement can lead to a poorly fitting frame, hindering the aesthetic appeal and structural integrity of the finished product. This section details the essential steps to ensure accurate rabbet depths, from initial measurement to final marking.Understanding the nuances of rabbet depth variations is the first step to achieving a perfect fit.

By accurately measuring and marking the desired depth, you guarantee that the frame and picture will align precisely. This meticulous approach avoids costly errors and ensures a beautiful, professional finish.

Measuring the Desired Rabbet Depth

To ensure a perfect fit, precise measurement of the rabbet depth is paramount. A variety of tools and methods are available to achieve this. A combination square, digital caliper, or even a precise ruler can be used, depending on the scale and the desired accuracy. The specific tool chosen should be appropriate for the size and type of project.

Methods for Marking Rabbet Depth

Several methods exist for marking the rabbet depth on the frame material. The chosen method depends on the specific project and the tools available. A common and accurate method involves using a combination square, a pencil, and a straight edge. The combination square allows for precise measurements and ensures that the mark is straight. Using a marking gauge and a template provides a reliable method, especially when dealing with multiple rabbets of identical depth.

Using a Combination Square for Precise Measurements

A combination square is an indispensable tool for accurate rabbet depth measurements. It allows for both linear and angular measurements, making it a versatile tool for woodworking projects. To use a combination square, first, position the square’s blade along the edge of the frame material, ensuring it’s aligned correctly. Next, using the square’s other part, carefully measure the desired rabbet depth and mark the line accordingly.

Marking a Rabbet Using a Template

Using a template provides a straightforward and efficient method for marking multiple identical rabbets. A template is a pre-cut piece of material that accurately represents the rabbet shape and dimensions. To use a template, first, carefully position the template on the frame material, aligning it precisely with the desired location. Next, trace the Artikel of the template onto the frame using a pencil or marking knife.

This ensures consistency and reduces the risk of errors, especially for complex or repetitive designs. Using a template guarantees consistent depth and shape for all rabbets.

Choosing the Right Tools for the Job

Crafting a precise rabbet requires the right tools. Just as a skilled chef needs the appropriate knives for each task, a woodworker needs the right tools for a flawless rabbet. The tools you select will determine the speed, accuracy, and overall quality of your work. From routers to chisels, each tool offers unique advantages and disadvantages that influence the final result.Understanding the capabilities and limitations of each tool is crucial for achieving the desired rabbet depth and achieving a professional finish.

This section will explore the essential tools, their functions, and how they compare in terms of effectiveness and precision, helping you make informed choices for your rabbet-cutting projects.

Essential Tools for Rabbeting

A variety of tools can be used for rabbeting, each with its own strengths. Understanding these differences allows you to select the best tool for your specific project.

- Routers: Routers are versatile power tools, particularly useful for creating consistent rabbets. Their rotating cutter bit can quickly and precisely shape the wood. Router bits are available in a wide range of shapes and sizes to accommodate different rabbet depths and widths. This versatility allows for complex rabbet designs and ensures a smooth and clean cut.

- Chisels: Chisels, especially when combined with a mallet, are manual tools providing excellent control and precision. They excel at achieving a clean, well-defined rabbet when combined with careful hand-crafting. The depth of the rabbet is meticulously controlled by the user. However, chisels are more time-consuming than routers and require significant skill to achieve a consistently accurate result. Different chisel types and sizes offer specific advantages for various wood thicknesses and rabbet widths.

- Rabbet Planes: Rabbet planes are specialized hand tools specifically designed for creating rabbets. They consist of a blade that fits precisely into the rabbet’s intended depth. These planes offer excellent control and allow for a clean and consistent rabbet. They are particularly useful for achieving precise depth and smooth surfaces. However, they can be more time-consuming than routers for larger rabbets.

Comparing Tools for Rabbeting

This table compares the effectiveness and precision of routers, chisels, and rabbet planes, highlighting their advantages and disadvantages.

| Tool | Effectiveness | Precision | Speed | Skill Required | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Router | High | High (with bit selection) | High | Medium | Fast, consistent, versatile for various shapes | Requires power source, can be noisy, may need bit adjustments |

| Chisel | High (with practice) | High (with skill) | Low | High | Excellent control, clean finish, minimal waste | Time-consuming, requires significant skill, less suitable for large rabbets |

| Rabbet Plane | Medium | High | Medium | Medium | Excellent control over depth, clean finish, good for specific rabbets | Time-consuming, less versatile than routers |

Advantages and Disadvantages of Different Tools

Choosing the right tool depends on factors like project scale, desired precision, and personal skill level.

Routers are ideal for large-scale projects and ensure consistent results. Chisels offer excellent precision for smaller projects, but require significant experience. Rabbet planes offer a balance between speed and precision. Considering these factors, a woodworker can select the appropriate tool to achieve a high-quality result.

Techniques for Creating a Deep Rabbet

Crafting a deep rabbet requires precision and the right approach. A well-executed deep rabbet is crucial for strong and aesthetically pleasing joints in woodworking projects, ensuring the frame and panel fit securely and remain stable over time. Understanding the various methods available, from the controlled precision of routers to the tactile artistry of hand tools, is essential for achieving a professional-quality result.Achieving a deep rabbet demands a method that balances efficiency with accuracy.

The best approach depends on the size of the project, the desired level of detail, and the tools at your disposal. Different methods offer varying levels of control, speed, and precision. Consider these factors when choosing your technique.

Router Methods for Deep Rabbets

Router methods offer a high degree of efficiency and precision, particularly when creating multiple rabbets of consistent depth. Routers provide the control necessary to achieve smooth and accurate cuts, especially when working with hard or dense woods. The key to success lies in proper setup and consistent pressure.

- Using a plunge router for a deep rabbet involves precisely setting the depth of cut and using a guide to ensure consistent depth throughout the cut. The plunge router’s ability to be adjusted during the cutting process allows for precision and control, crucial for a perfect rabbet. This method is particularly effective for repeatable rabbet cuts in large projects.

- Employing a router with a fixed base and a router bit designed for rabbeting allows for a steady and consistent cut. This approach is ideal for projects requiring consistent depth and a smooth finish, but requires careful measurement and planning to ensure the initial cut is accurate. The fixed base provides a stable platform for a controlled and consistent cut, crucial for projects needing repeatability.

Hand-Tool Methods for Deep Rabbets

Hand-tool methods, while requiring more time and effort, offer a tangible connection to the craft. The tactile experience of working with hand tools provides a deeper understanding of the material and the cut. These methods are often favored by woodworkers seeking a more intimate connection with their work.

- Achieving a deep rabbet using hand tools requires patience and precision. Using a chisel and mallet, carefully and methodically remove material, ensuring consistent depth and straight lines. This method allows for fine control over the shape and depth of the rabbet, and can result in a beautiful and refined finish. The technique requires consistent effort and patience.

Template Methods for Deep Rabbets

Template methods provide a consistent and accurate way to create multiple rabbets of identical dimensions. Using a template ensures repeatability and minimizes errors, particularly useful for production work or projects with multiple identical components.

- Creating a template for a deep rabbet involves carefully marking the desired shape and depth on a piece of material, then cutting it out. This template is then used as a guide to cut the rabbets on other pieces of material, ensuring identical dimensions. The precision and efficiency of this approach are valuable for large-scale projects.

Comparing Methods for Deep Rabbets

| Method | Pros | Cons |

|---|---|---|

| Router | High speed, precision, repeatable cuts, efficient for multiple rabbets | Requires specialized equipment, potential for damage if not used carefully |

| Hand Tools | Direct connection to the wood, fine control over shape and depth, often more affordable | Time-consuming, requires significant skill and experience, less efficient for large projects |

| Template | Consistency, repeatability, minimized errors, useful for production | Requires extra time for template creation, limited flexibility |

Preventing Common Mistakes

Crafting a perfect rabbet, especially a deep one, demands precision. A misstep can lead to frustration, wasted materials, and a final product that doesn’t meet expectations. Understanding the potential pitfalls and how to avoid them is crucial to successful woodworking.Common mistakes often stem from a lack of attention to detail, improper tool selection, or rushed execution. By anticipating these errors and implementing preventive measures, you’ll significantly improve your success rate and create beautiful, accurate joinery.

Identifying Common Rabbet Errors

Deep rabbets, while visually appealing, present unique challenges. Incorrect measurements, inadequate support for the workpiece, and improper tool use can lead to inaccurate cuts, material damage, and uneven rabbets. Understanding these potential issues allows for proactive problem-solving.

Causes of Rabbet Cutting Errors

- Inaccurate Measurements: A slight miscalculation in measuring the rabbet depth or width can quickly throw off the entire project. This can be due to imprecise use of measuring tools or a misunderstanding of the intended dimensions.

- Improper Support: A workpiece that flexes or moves during the cutting process can lead to an uneven rabbet. Insufficient clamping or support, especially for large or intricate pieces, can lead to significant errors.

- Inadequate Tool Selection: Using the wrong blade type, sharpness, or the incorrect router bit or saw for the rabbet size can lead to tear-out, inaccurate cuts, and excessive effort. A dull blade will also contribute to inaccuracies and potentially damage the material.

- Rushed Execution: Rushing through the process, especially when using intricate tools or complex techniques, is a common cause of errors. Carefully taking each step and double-checking measurements will drastically reduce errors.

- Material Variations: Different wood types have varying densities and grain patterns. These factors can influence how the wood responds to the cutting process, leading to inconsistencies. Recognizing these variations is important for adapting your techniques and ensuring even cuts.

Avoiding Rabbet Cutting Mistakes

Thorough preparation and meticulous execution are key to avoiding common mistakes. Begin by accurately measuring the rabbet depth and width, ensuring precise marks. Employ sturdy clamps and supports to keep the workpiece stable during cutting. Ensure your tools are sharp and in good working condition. Taking your time to carefully complete each step is a key element of preventing errors.

Troubleshooting Rabbet Cutting Issues

- Tear-out: If tear-out occurs, check the blade sharpness. A dull blade will exacerbate this issue. Adjust the feed rate and ensure proper support for the workpiece. Consider using a different blade type for a better result. Adjusting the angle of the blade can also help.

- Uneven Rabbets: Uneven rabbets often indicate an issue with workpiece support or an inconsistency in the cutting process. Ensure the workpiece is firmly clamped and that the tool is running smoothly. Consider adjusting the speed of the tool and the cutting angle.

- Incorrect Depth: If the rabbet depth is incorrect, re-measure carefully. Double-check the measurements and ensure the blade is set correctly. Use a depth gauge to verify the depth of the cut.

- Material Damage: If the material is damaged, reassess the support, tool sharpness, and feed rate. Ensure that the tool is running at the appropriate speed for the material. Using a different blade type might also be helpful. Avoid rushing the process.

Potential Problems of Inappropriate Tools

Using inappropriate tools can lead to a variety of issues, including inaccurate cuts, tear-out, and material damage. A dull blade will significantly reduce the quality of the cut and increase the risk of tear-out. Improperly selected router bits or saws can lead to inconsistent cuts or significant difficulty in achieving the desired rabbet depth. Choosing the right tool for the job is essential for creating a precise and professional-looking rabbet.

Considerations for Wood Type and Frame Design

Choosing the right wood for a frame, especially one with a deep rabbet, is crucial for both aesthetic appeal and structural integrity. The characteristics of the wood directly influence the rabbet’s ability to hold the picture securely and resist warping over time. Different woods react differently to moisture and stress, impacting the longevity and stability of the entire frame.Understanding the interplay between wood type and frame design is essential for creating a lasting piece of art.

Factors like grain patterns, density, and moisture content significantly affect the success of a deep rabbet. Selecting appropriate wood species ensures the frame can accommodate the depth required without compromising its strength or appearance.

Wood Type and Rabbet Depth

Wood types vary considerably in their density and hardness. Denser woods, like hardwoods, generally offer greater resistance to warping and cracking, making them suitable for deep rabbets. Softer woods, like pine or fir, may not provide the same level of structural support and might require shallower rabbets. Consider the specific weight and dimensions of the picture that will be housed within the frame when selecting a wood type for a deep rabbet.

The picture’s weight will contribute to the stress on the rabbet, thus the density of the wood becomes even more important.

Factors in Designing a Frame with a Deep Rabbet

Designing a frame with a deep rabbet requires careful consideration of several elements. The thickness of the frame’s molding, the overall shape and profile, and the size of the picture all play a critical role. A thicker frame, particularly with a complex profile, can create greater structural integrity, allowing for a deeper rabbet without compromising the frame’s stability.

Likewise, the size of the picture influences the stress placed on the rabbet and, consequently, the type of wood that is most appropriate.

Frame Designs Benefitting from Deep Rabbets

Certain frame designs naturally benefit from a deep rabbet. Antique-style frames, often with elaborate carvings and intricate details, can use a deep rabbet to securely hold the picture while accentuating the frame’s artistic qualities. Frames with substantial molding or a large picture size require deep rabbets for both aesthetic and structural reasons. Contemporary designs featuring minimal profiles might still require a deep rabbet if the picture is exceptionally large or heavy.

In this instance, the wood’s density and the frame’s structure need careful evaluation.

Selecting Wood Types for Deep Rabbets

When selecting wood types for frames with deep rabbets, hardwoods are generally preferred due to their density and durability. Maple, oak, cherry, and walnut are excellent choices, each possessing unique aesthetic qualities. Their strength makes them well-suited for supporting the stress exerted by the picture and the depth of the rabbet. However, consider the specific wood’s grain patterns.

Some woods may exhibit more pronounced grain variations, which might impact the overall appearance of the finished frame. A deep rabbet can sometimes accentuate or hide grain patterns, so selecting a wood with a grain that suits the overall design is critical.

Maintaining Accuracy During the Process

Crafting a picture frame with a precise rabbet is like sculpting a miniature masterpiece. Every millimeter counts, and maintaining accuracy throughout the entire process is crucial for achieving a professional-looking and functional frame. Small variations in depth can significantly impact the frame’s aesthetic appeal and its ability to hold the artwork securely. This section dives deep into the strategies for maintaining consistent rabbet depth, ensuring your frame is a testament to your woodworking skills.Maintaining consistent depth throughout the rabbeting process is vital for a visually appealing and structurally sound frame.

Variations in depth lead to uneven joints, gaps, and an overall lack of finesse. Precise measurements and careful execution at each stage are key to success.

Importance of Consistent Depth

Maintaining consistent depth throughout the rabbeting process is crucial for several reasons. First, it ensures a visually appealing frame. Uneven rabbets create an unprofessional look, detracting from the overall aesthetic. Second, consistent depth guarantees a secure fit between the frame and the artwork. Irregularities in the rabbet can lead to the artwork shifting or falling out.

Finally, a perfectly executed rabbet enhances the frame’s structural integrity, ensuring it holds the artwork securely over time.

Techniques for Ensuring Consistent Depth

Several techniques can help ensure consistent rabbet depth. One key technique is to use a well-maintained and accurate measuring tool. Repeatedly checking the depth throughout the process will identify any inconsistencies before they become problematic. Using a combination of a depth gauge and a measuring tape can further enhance the accuracy of your measurements.

- Establish a Precise Baseline: Begin by meticulously measuring and marking the desired rabbet depth on the wood. Use a marking gauge or a sharp pencil to transfer these measurements to all the relevant pieces. This baseline ensures all subsequent cuts are based on the same, accurate depth.

- Regular Verification: As you work, use a depth gauge to regularly verify the depth of the rabbet at various points. This method allows you to identify and correct any deviations early on, minimizing the impact of errors.

- Maintaining a Stable Cutting Surface: Ensure the wood is firmly secured on a stable surface during the cutting process. Any movement or instability during cutting can lead to inconsistencies in the rabbet depth.

Using Measuring Tools to Monitor Depth

A depth gauge is an invaluable tool for monitoring rabbet depth. It allows for precise measurements during the cutting process. Using a depth gauge alongside a ruler ensures accuracy and prevents errors. When using a depth gauge, place it in the rabbet after each cut to confirm that the depth matches the predetermined measurement. This technique helps you avoid cutting too deep or too shallow, ensuring a consistent result.

| Tool | Function |

|---|---|

| Depth Gauge | Precisely measures the depth of the rabbet. |

| Measuring Tape | Measures the overall dimensions of the frame pieces. |

| Marking Gauge | Transfers measurements to the wood. |

Examples of Inconsistent Rabbets

Inconsistent rabbet depth can lead to several issues. A rabbet that is too shallow might not hold the artwork securely, leading to potential damage. A rabbet that is too deep could result in an unsightly overhang or cause the frame to look unstable. A consistent and accurate rabbet is critical to achieving a well-made, aesthetically pleasing, and structurally sound picture frame.

Finishing Touches and Considerations

Transforming a raw rabbet into a polished, museum-quality frame involves more than just precise cuts. The finishing touches are crucial, not only for aesthetics but also for the longevity and protection of the frame. A well-executed finish seals the wood, prevents moisture damage, and elevates the overall presentation of your work. Proper preparation and selection of the right finish are key components of this final stage.The rabbet, once meticulously shaped, demands careful attention to detail in its finishing.

Preparing the surface for a superior finish is as important as the initial shaping. This involves removing any imperfections, ensuring a smooth, consistent surface ready to receive the chosen finish.

Preparing the Rabbet for Finishing, How to deepen a picture frame rabbet depth

Proper surface preparation before applying any finish is paramount. This ensures the finish adheres evenly and provides a long-lasting protective layer. Dust, debris, and any unevenness can create imperfections in the final finish. A smooth surface is essential for a professional look. Begin by thoroughly cleaning the rabbet with a soft brush and tack cloth to remove any dust or residue.

Use fine-grit sandpaper (e.g., 220-400 grit) to smooth out any imperfections or scratches. Wipe the area clean again to remove any sanding dust before proceeding. For deep rabbets, consider using a sanding block for even sanding and to avoid over-sanding.

Selecting the Appropriate Finish

The choice of finish directly impacts the appearance and longevity of the frame. A finish’s ability to withstand environmental factors, like moisture and UV exposure, is vital. The depth of the rabbet plays a role in the type of finish. A deep rabbet might benefit from a more durable and potentially thicker finish, whereas a shallow one might allow for a more delicate and transparent finish.

Consider the overall aesthetic of the frame, and the type of wood used when selecting the finish. For example, a glossy finish might not be suitable for a rustic frame, whereas a matte finish might suit a modern design.

Finishing Techniques

Applying the finish requires precision and patience. The chosen technique significantly influences the final appearance and durability. Several methods are available. A brush application offers control, but can result in brush marks if not carefully applied. A spray application provides even coverage but requires a controlled environment.

For deep recesses, a foam brush or a small angled brush might be ideal.

- Applying the Finish: Apply the finish in thin, even coats, allowing each coat to dry completely before applying the next. Avoid applying too much finish in one go. Multiple thin coats will provide better protection and a smoother finish than one thick coat. This technique minimizes the risk of drips and unevenness.

- Drying Time and Coats: Follow the manufacturer’s instructions for drying time between coats. Allow ample drying time to avoid issues like cracking or bubbling. The number of coats required depends on the finish type and desired opacity.

- Finishing Touch-ups: After the final coat has dried, inspect the frame for any imperfections. Use a fine-grit sandpaper (e.g., 400-600 grit) to gently address any minor imperfections. Then, apply a final coat of finish, ensuring a flawless finish.

Considerations for Different Wood Types

Different woods react differently to finishes. For example, hardwoods often require more coats of finish than softwoods to achieve adequate protection. The density of the wood also impacts the finish’s ability to penetrate and adhere. Consider the wood’s natural characteristics when selecting the appropriate finish and application method. For example, a finish that is too glossy might highlight imperfections in a wood with a natural grain pattern.

Final Thoughts

In conclusion, deepening a picture frame rabbet depth involves careful planning, precise measurements, and the skillful application of appropriate tools and techniques. By following the steps Artikeld in this guide, you can create picture frames with a professional finish and a truly unique aesthetic. Remember to prioritize accuracy and safety throughout the process.

FAQs

What are the common mistakes when creating a deep rabbet?

Common mistakes include using inappropriate tools, failing to maintain consistent depth across the rabbet, and not accounting for wood grain variations. These issues can lead to inaccuracies and damage to the frame material.

How does wood type affect rabbet depth?

Different woods have varying hardness and grain structure. Hardwoods often require more precise measurements and potentially different tools than softer woods. Consider the wood’s properties when choosing the appropriate rabbet depth and cutting method.

What are the advantages and disadvantages of using a router for creating a deep rabbet?

Routers offer precise and efficient rabbeting, particularly for deep rabbets. However, they require careful setup and potentially more practice than hand tools. Hand tools, on the other hand, offer more control but can be time-consuming for deep rabbets. Consider the desired level of precision and your skill level when making your choice.

How do I ensure consistent depth across the entire rabbet?

Using a measuring tool to monitor and verify rabbet depth throughout the process, along with consistent pressure and technique, are essential for achieving uniform depth. Regular checks and adjustments are key.