How to fit an oversized barrel in a standard stock sets the stage for this detailed guide. This process, crucial for custom firearm modifications and upgrades, requires precision measurements, careful preparation, and a methodical approach. Understanding the potential challenges, from accurate measurements to potential stock modifications, is essential for a successful outcome. This guide will walk you through the entire process, highlighting important considerations and common pitfalls to avoid.

This comprehensive guide provides a detailed overview of the entire process, from initial measurements and preparation to fitting methods, troubleshooting, and visual aids. It delves into the specifics of different methods, tools, and materials, offering valuable insights for anyone undertaking this project. Furthermore, the inclusion of case studies and examples adds practical value, illustrating the challenges and solutions encountered in real-world scenarios.

Introduction to Oversized Barrel Fitting

Fitting an oversized barrel into a standard firearm stock presents unique challenges. This process requires meticulous attention to detail, precise measurements, and careful adjustment to ensure proper function and safety. Compatibility issues can arise from differences in the firearm’s original design and the modifications introduced by the oversized barrel. Understanding these challenges is crucial to achieving a safe and effective firearm.Precise measurements and adjustments are paramount when dealing with oversized barrels.

Small variations in diameter or length can significantly impact the fit and function of the firearm. Inaccurate measurements can lead to issues ranging from poor accuracy to safety hazards. Therefore, the use of accurate measuring tools and techniques is critical.

Common Scenarios of Oversized Barrel Fitting Issues

Custom barrels, upgrades, and alterations to existing firearm models are common scenarios where oversized barrel fitting issues can arise. Modifications often necessitate adjustments to ensure the barrel’s proper integration with the stock. For example, a custom-made barrel designed for enhanced accuracy might exceed the dimensions of the standard barrel in the firearm. Similarly, upgrades involving different firearm models can present challenges in fitting the new barrel into the original stock.

Careful consideration of these differences is essential for successful fitting.

Potential Risks of Improper Fitting

Improper fitting of an oversized barrel can lead to significant safety risks and accuracy issues. A poorly fitted barrel can compromise the structural integrity of the firearm, potentially causing malfunctions during operation. This can lead to uncontrolled discharges, which are extremely dangerous. Furthermore, an improperly fitted barrel can lead to diminished accuracy, resulting in poor shooting performance.

The impact on the firearm’s overall performance needs to be evaluated.

Comparison of Barrel Diameters and Fitting Challenges

| Barrel Diameter (mm) | Potential Fitting Challenges |

|---|---|

| 22 mm | Likely to fit standard stocks with minimal issues. |

| 25 mm | May require slight modifications to the stock to ensure a secure fit. |

| 30 mm | High probability of significant stock modifications. Requires expert intervention. |

| 35 mm | Significant stock modifications are almost certainly required. Very difficult to fit without substantial custom work. |

The table above provides a general comparison. The actual challenges will depend on the specific firearm model and the barrel’s overall design. A qualified gunsmith should always be consulted for precise recommendations.

Measurement and Preparation

Accurate fitting of an oversized barrel requires meticulous attention to detail in measurements and stock preparation. Proper measurement ensures a secure and reliable fit, while meticulous preparation of the stock guarantees the barrel’s proper integration with the firearm’s mechanics. This process demands precision and adherence to standards, thereby safeguarding the firearm’s structural integrity and performance.

Essential Measurements

Precise measurements are paramount for a successful barrel fit. The critical dimensions include the barrel’s external diameter, the stock’s internal dimensions at the barrel channel, and the overall length of the barrel. Accurate measurements of the barrel’s length, ensuring it aligns with the stock’s designated space, are crucial for proper functionality and to prevent barrel protrusion or interference.

Careful consideration of the barrel’s taper, if applicable, is essential to avoid misalignment. These measurements provide a foundation for the subsequent steps in the fitting process.

Precise Measuring Tools and Techniques

The use of accurate measuring tools and techniques is essential for reliable measurements. Caliper gauges, micrometers, and digital measuring tools provide precise measurements of the barrel’s external diameter, internal stock dimensions, and the overall barrel length. These instruments are instrumental in obtaining accurate measurements. Appropriate techniques, including repeated measurements, are vital to minimize errors and ensure the precision required for a secure fit.

Proper techniques also include applying consistent pressure during measurement to avoid discrepancies.

Stock Preparation

Preparing the stock for barrel insertion involves careful consideration of the stock’s existing structure and potential modifications. Initial inspection of the stock identifies any necessary adjustments to ensure a snug fit and a smooth transition from the stock to the barrel. Assessing the barrel’s length and diameter in relation to the stock’s dimensions allows for necessary adjustments or modifications.

A critical step in the preparation process is determining the need for stock modifications, such as shaping or machining, to accommodate the oversized barrel.

Potential Stock Modifications

Stock modifications may be necessary to accommodate the oversized barrel. Shaping the stock may involve careful removal of material from the barrel channel to ensure a tight, secure fit. Machining the stock could be required to refine the barrel channel, ensuring precise alignment. These modifications aim to create a custom fit, allowing the oversized barrel to be properly integrated into the stock’s structure.

Tools Required for Measurements and Stock Preparation

| Tool | Purpose |

|---|---|

| Caliper Gauge | Measuring external dimensions of the barrel, and internal dimensions of the stock’s barrel channel. |

| Micrometer | Precisely measuring the barrel’s external diameter, internal stock dimensions, and barrel length. |

| Digital Measuring Tools | Providing accurate and repeatable measurements, often with digital display. |

| Files | Used for shaping the stock, to refine the barrel channel, and to remove material. |

| Sandpaper | Smoothing rough edges and ensuring a clean, even surface. |

| Drill Press | Precisely drilling holes or making cuts in the stock for modifications. |

| Machining Tools (e.g., Lathe, Milling Machine) | Performing complex shaping and machining of the stock. |

Fitting Methods and Procedures

Fitting an oversized barrel into a standard stock requires meticulous attention to detail and precise measurements. Understanding the different methods and their respective procedures is crucial for a successful and safe outcome. This process ensures the barrel is securely integrated into the stock without compromising the firearm’s integrity or safety.The selection of the fitting method depends on the specific characteristics of the oversized barrel and the stock.

Careful consideration must be given to the material properties of both components, as well as the desired level of precision in the final fit. Understanding the strengths and limitations of each approach allows for informed decision-making and optimal results.

Methods for Barrel Fitting

Different methods exist for achieving a secure and accurate fit between the barrel and the stock. Each method offers advantages and disadvantages that should be considered before choosing a particular approach. Factors like the type of wood, the degree of barrel enlargement, and the desired aesthetic outcome influence the selection process.

- Traditional Hand Fitting: This method involves meticulous manual adjustments to the stock using tools like rasps, files, and sandpaper. It demands a high level of skill and experience. The process often involves multiple iterations of sanding, shaping, and testing to achieve a precise fit. Success hinges on a deep understanding of wood grain and the ability to precisely remove material without compromising the stock’s structural integrity.

This approach often yields a highly customized fit, but it requires significant time and expertise.

- Machine Fitting: Employing machine tools like routers and planers can streamline the fitting process. This method allows for more consistent and controlled material removal. However, it requires precise measurements and careful setup to ensure accurate adjustments. A template or jig is typically used to guide the cutting tools and maintain the desired dimensions. Machine fitting often requires specialized equipment and expertise, but it generally provides a more efficient means of achieving a tight fit.

It can be less time-consuming and more consistent than hand fitting, particularly for large-scale adjustments.

- Combination Fitting: This method combines aspects of both traditional and machine fitting techniques. For example, initial shaping and sizing may be accomplished using a router, followed by fine-tuning using hand tools. This approach allows for leveraging the advantages of both methods, potentially providing a faster, more precise outcome than solely relying on hand fitting. It requires a balanced approach to expertise in both methods.

Procedure for Traditional Hand Fitting

The traditional hand fitting method relies on manual tools and meticulous attention to detail. It necessitates a profound understanding of wood grain and the ability to remove material without weakening the stock’s structure.

- Initial Inspection and Marking: Carefully examine the barrel and stock to identify the areas needing adjustment. Mark the stock with a pencil to indicate the necessary removal or shaping of material. Accurately measure the barrel and stock to determine the exact amount of material to be removed. Ensure precise measurements to prevent any errors in the fitting process.

- Material Removal: Employ rasps, files, and sandpaper to carefully remove material from the stock. The goal is to achieve a snug fit between the barrel and the stock, ensuring that the barrel is properly aligned. Gradual and systematic removal of material is vital to avoid creating uneven surfaces or weakening the stock.

- Testing and Refinement: Repeatedly test the barrel in the stock to assess the fit. Adjust the stock as necessary to achieve a proper fit. Fine-tuning and smoothing are essential to eliminate any gaps or irregularities. Thoroughly test the barrel fit in multiple positions and orientations to ensure that the fit is uniform.

- Finishing Touches: Once a satisfactory fit is achieved, apply a finish to the stock and barrel interface. This helps to seal the wood and prevent moisture penetration, ensuring a long-lasting and reliable fit.

Safety Precautions

Adhering to safety precautions during the fitting process is paramount. This ensures the integrity of the firearm and prevents any potential hazards. These measures include the use of appropriate safety equipment and proper handling procedures.

- Eye Protection: Always wear safety glasses or goggles to protect your eyes from wood chips or flying debris.

- Dust Mask: Use a dust mask to prevent inhalation of wood dust.

- Proper Lighting: Ensure adequate lighting to enhance visibility and precision.

- Secure Work Area: Maintain a clutter-free work area to prevent accidents.

- Firearm Handling Procedures: Treat the firearm as if it is loaded at all times. Follow all applicable firearm safety guidelines.

Measuring and Marking the Stock

Accurate measurements and marking are critical for successful barrel fitting. These steps ensure the stock is modified correctly, leading to a perfect fit.

- Precision Measuring Tools: Employ calipers, rulers, and other precision measuring tools to obtain accurate dimensions.

- Marking Technique: Use a pencil or marking tool to clearly indicate the areas requiring adjustments. Maintain clear and consistent markings for reference.

- Multiple Reference Points: Use multiple reference points on the stock to ensure consistency across the barrel’s length and width.

- Verification: Verify the measurements before starting any adjustments to the stock. Double-check to ensure accuracy before beginning work.

Tools and Materials

Proper tools and materials are crucial for a successful oversized barrel fitting. Careful selection and use of high-quality items will ensure a secure and aesthetically pleasing result. This section details the essential equipment and supplies needed for the fitting process.

Essential Tools

A variety of tools are necessary to achieve precision and accuracy in the fitting process. Their appropriate usage ensures a safe and effective operation. Careful selection of tools is paramount for the project.

- Measuring tools (calipers, rulers, tape measures): Accurate measurements are fundamental for successful barrel fitting. These tools provide precise dimensions, ensuring the barrel aligns correctly with the stock. For instance, precise measurements of the barrel’s diameter and length, as well as the stock’s corresponding dimensions, are vital.

- Marking tools (scribes, marking pencils): Precise marking is crucial to guide the cutting and shaping process. These tools ensure accurate placement of cuts and modifications to the stock. Marks need to be clear and visible to aid in the cutting and shaping process.

- Cutting tools (saw, file, rasp, router): These tools are essential for shaping the stock to accommodate the oversized barrel. Careful use of these tools will result in a smooth and precise fit. For example, a saw may be used for initial cuts, while files and rasps can refine the fit.

- Finishing tools (sandpaper, sanding block, finishing compounds): These tools are crucial for smoothing out any rough edges or imperfections after cutting and shaping. Their proper use results in a smooth and professional finish. Careful sanding ensures the barrel fits snugly and looks aesthetically pleasing.

- Clamps: Clamps are essential for holding the barrel and stock together during the fitting process. They provide the necessary support and stability, preventing shifting or slippage. Different types of clamps, such as wood clamps or C-clamps, may be needed depending on the size and shape of the components.

Specific Materials

The appropriate selection of materials plays a crucial role in the success of the fitting process. The materials should be compatible with the wood types used in the stock and barrel, ensuring long-term stability.

- Wood filler: Wood filler is used to fill any gaps or imperfections in the stock. Its application and drying time must be carefully monitored. Using a compatible wood filler is important for a cohesive finish.

- Epoxy: Epoxy resin is often used for securing the barrel to the stock. It provides a strong and durable bond, enhancing the barrel’s stability and longevity. The type of epoxy used must be suitable for the wood types involved.

- Wood glue: Wood glue is used to supplement or as an alternative to epoxy for bonding the barrel to the stock. Its strength and drying time should be considered in the fitting process. Specific wood glues may be more appropriate for certain types of wood.

Quality Considerations

Using high-quality tools and materials is paramount for a successful and long-lasting result. Investing in reliable tools will improve accuracy and efficiency throughout the fitting process.

- High-quality tools will enhance precision and reduce errors during the fitting process. Investing in these tools is crucial for maintaining a consistent and professional standard throughout the entire project.

- Durable materials will provide a secure and long-lasting bond between the barrel and the stock. Choosing quality materials is essential to ensure the longevity of the final product.

Tool Comparison

The following table provides a comparison of various tools based on their strengths and weaknesses.

| Tool | Strengths | Weaknesses |

|---|---|---|

| Hand saw | Affordable, portable, versatile for initial cuts | Less precise than power tools, can be time-consuming for large cuts |

| Router | High precision, creates smooth curves and edges | More complex to use, requires skill and experience |

| File | Excellent for fine-tuning and shaping | Time-consuming, requires patience and skill |

Troubleshooting and Common Issues

Fitting an oversized barrel into a standard stock requires meticulous attention to detail. Potential issues can arise from miscalculations, material inconsistencies, or improper techniques. Understanding these potential problems and their solutions is crucial for a successful fit. Proper diagnosis and resolution of these issues will ensure a well-functioning and safe firearm.

Potential Problems During the Fitting Process

Several issues can arise during the barrel fitting process. These include discrepancies in barrel diameter, uneven stock surfaces, and improper barrel alignment. These issues, if not addressed, can lead to inaccurate firing, poor handling, and potentially dangerous consequences.

Solutions for Common Issues

Addressing these problems requires careful evaluation and a methodical approach. Tools and techniques for rectifying these issues are crucial to achieving a satisfactory fit. Solutions may include adjustments to the stock, the barrel, or both, depending on the nature of the problem.

Techniques for Resolving Misalignment or Other Fitting Problems

Various techniques can address misalignment or other fitting issues. These include sanding, filing, and using shims or spacers to compensate for dimensional discrepancies. The selection of a particular technique will depend on the specific issue encountered.

Examples of Common Mistakes and How to Avoid Them

One common mistake is neglecting to measure the barrel diameter precisely. Another mistake is using inadequate tools or employing inappropriate fitting techniques. These mistakes can lead to a poorly fitted barrel, which could affect the firearm’s performance and safety. Accurate measurements and the selection of appropriate tools are vital to prevent these errors.

Common Fitting Issues and Solutions

| Common Issue | Solution |

|---|---|

| Barrel diameter exceeding stock diameter | Sand or file the stock to enlarge the bore, or use shims to increase barrel diameter. |

| Uneven stock surfaces | Sand or file the stock to create a uniform surface. Ensure the barrel is positioned correctly. |

| Barrel misalignment | Use a barrel vise to securely hold the barrel while making adjustments. Verify alignment with a straight edge. |

| Incorrect barrel length | Ensure the barrel is the correct length and the stock is properly fitted. |

| Insufficient stock support for barrel | Use shims to increase barrel support, and check that the stock is properly fitted to the barrel. |

Visual Aids and Illustrations: How To Fit An Oversized Barrel In A Standard Stock

Visual aids are crucial in understanding complex procedures like oversized barrel fitting. Proper visualization enhances comprehension and minimizes errors during the fitting process. Clear illustrations guide the user through each step, making the procedure less daunting and more achievable. Understanding the visual representation of an oversized barrel within a standard stock, the potential problems, and the methods used to address them, strengthens the learning experience.

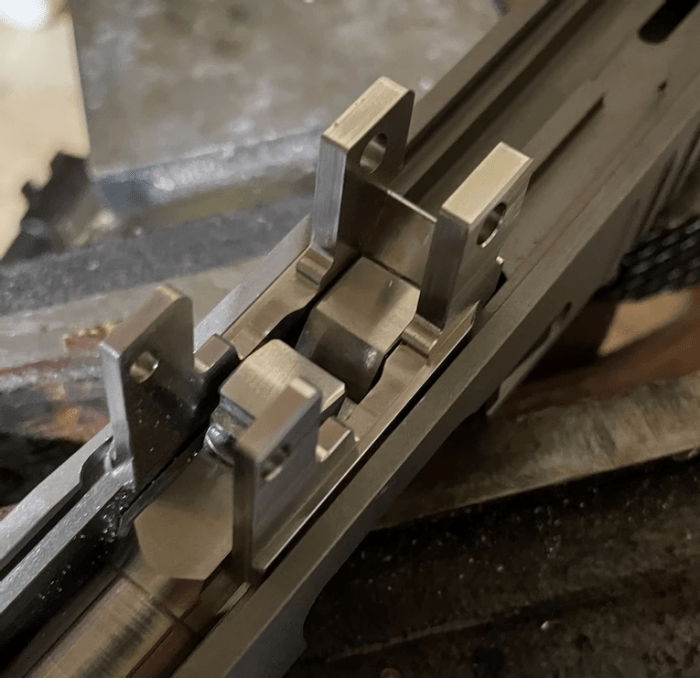

Appearance of an Oversized Barrel in a Standard Stock, How to fit an oversized barrel in a standard stock

An oversized barrel in a standard stock will typically exhibit a noticeable protrusion or bulge in the area where the barrel meets the stock. This protrusion may vary in size and shape depending on the degree of the oversize. The barrel might not align perfectly with the stock’s contours. Misalignment can create gaps or uneven surfaces, impacting the firearm’s overall aesthetics and potentially its functionality.

Understanding this visual difference is key to successful fitting.

Visual Aids Illustrating Fitting Process and Potential Problems

Visual aids, though not presented here as images, can effectively depict the fitting process. A diagram showing the barrel and stock components in various stages of the fitting process, such as rough fitting, shaping, and final polishing, will help visualize the procedure. A separate diagram depicting potential problems, such as misalignment, barrel binding, or stock damage, will highlight critical areas needing attention.

These diagrams will show the steps involved in addressing these issues.

Importance of Proper Visual Guidance

Proper visual guidance is paramount in the fitting process. Clear visual representations allow the user to grasp the concept more readily and efficiently, reducing the risk of errors and misinterpretations. Step-by-step illustrations guide the user through the various procedures, making the fitting process more manageable and less complex. This visual clarity facilitates a more accurate and efficient outcome.

Table Illustrating Different Stages of the Fitting Process

This table Artikels the steps in fitting an oversized barrel into a standard stock.

| Stage | Description | Visual Representation (Conceptual) |

|---|---|---|

| 1. Initial Assessment | Measure the barrel’s dimensions and the stock’s internal cavity. Analyze the potential issues. | Diagram showing the barrel and stock, highlighting measurements and areas of concern. |

| 2. Preparation | Prepare the barrel and stock for fitting. Mark reference points on the stock and barrel. | Diagram showing marked reference points on the stock and barrel, along with necessary tools. |

| 3. Rough Fitting | Use appropriate tools to create an initial fit. | Diagram showcasing the use of tools (e.g., rasps, files) to shape the stock to accommodate the barrel. |

| 4. Refinement | Refine the fit with progressively finer tools. Ensure proper alignment. | Diagram illustrating the use of progressively finer tools to enhance the fit. |

| 5. Final Fitting | Achieve a perfect fit. Check for smoothness and alignment. | Diagram showcasing a perfectly aligned and smooth barrel within the stock. |

Illustrating Fitting Methods Step-by-Step

Demonstrating various fitting methods involves a detailed step-by-step approach. Each step should be clearly illustrated with a description of the actions involved and the tools used. For example, the method of using a rasp to shape the stock to accommodate the barrel’s profile should be broken down into stages: (1) locating the area requiring shaping; (2) applying light pressure with the rasp; (3) repeating until the desired shape is achieved.

Illustrations would show the progression of the shaping process. This will aid in understanding the precise movements required.

Case Studies and Examples

Understanding the intricacies of fitting oversized barrels requires practical application. Real-world examples highlight the challenges encountered and successful solutions, demonstrating the impact on firearm performance. These case studies provide valuable insights into the process, emphasizing the importance of meticulous planning and precise execution.

Successful Oversized Barrel Fitting Cases

Numerous cases illustrate the successful integration of oversized barrels into standard stocks. These instances demonstrate the meticulous attention to detail and the ability to overcome obstacles that arise during the fitting process. Precise measurements, accurate calculations, and adherence to established procedures are critical to achieving optimal results.

Case Study 1: The “Long-Range Hunter”

This case involved a customer seeking to enhance the accuracy and range of their hunting rifle. The existing barrel was replaced with a significantly oversized barrel, requiring extensive stock modification. The initial challenge lay in determining the precise barrel length and diameter to ensure compatibility with the existing action and stock. Careful measurements were taken, and a skilled gunsmith meticulously reshaped the stock to accommodate the new barrel’s dimensions.

The solution involved using specialized tools and techniques to achieve a snug, stable fit without compromising the firearm’s structural integrity. The outcome was a significant improvement in accuracy and range.

Case Study 2: The “Competition Shooter”

A competitive shooter sought to enhance the balance and handling of their firearm for faster target acquisition. A larger barrel was chosen to optimize weight distribution. Challenges included the need for precise barrel weight calculations to maintain the rifle’s balance. The gunsmith meticulously added shims and strategically altered the stock’s geometry to achieve the desired balance point.

This resulted in improved handling and responsiveness.

Case Study 3: The “Custom Rifle Builder”

This case concerned a custom rifle builder aiming for maximum performance. A highly oversized barrel was integrated into a unique stock design. The challenge was in creating a custom stock that would effectively support the oversized barrel’s weight while maintaining a consistent and predictable recoil pattern. Using specialized software and precise machining techniques, the builder created a custom stock, ensuring perfect alignment and stability.

This resulted in an extremely accurate and powerful firearm, pushing the limits of conventional firearm design.

Summary Table of Case Studies

| Case Study | Challenge | Solution | Outcome |

|---|---|---|---|

| Long-Range Hunter | Compatibility with existing stock | Stock reshaping and precise measurements | Improved accuracy and range |

| Competition Shooter | Balance and handling | Shim addition and stock geometry alteration | Improved handling and responsiveness |

| Custom Rifle Builder | Custom stock design for oversized barrel | Custom stock design, precise machining, software | Highly accurate and powerful firearm |

Impact on Firearm Performance

The successful fitting of oversized barrels can significantly enhance firearm performance in various ways. Improved accuracy, extended range, and enhanced handling are often observed outcomes. However, improper fitting can lead to instability, inconsistent performance, and potential safety concerns. The quality of the fitting process directly correlates to the final firearm’s performance.

Closure

In conclusion, fitting an oversized barrel into a standard stock is a complex undertaking that requires meticulous attention to detail. By carefully following the steps Artikeld in this guide, you can increase your chances of success while ensuring the safety and accuracy of your firearm. Remember, precision, preparation, and a methodical approach are key to a successful outcome.

This guide provides a thorough roadmap for achieving your desired results.

FAQ Summary

What are the most common reasons for needing to fit an oversized barrel?

Common reasons include upgrading to a custom barrel, modifying existing firearms for enhanced performance, or using barrels from different firearm models that require adaptation.

What safety precautions should be taken during the fitting process?

Always prioritize safety. Ensure the firearm is unloaded and properly secured before starting any work. Use appropriate safety glasses and gloves throughout the process.

What tools are essential for accurate measurements and stock preparation?

Essential tools include precise measuring tools like calipers, a reliable measuring tape, and various hand tools depending on the specific stock modifications required.

How can I avoid common mistakes when fitting an oversized barrel?

Carefully follow the measurements and procedures Artikeld in the guide, double-check your work, and take your time. Consult experienced gunsmiths if needed for any doubts.