How to fix a car port? This comprehensive guide provides a detailed roadmap for addressing various car port issues, from minor maintenance to complex repairs. Understanding the different types of car ports, common problems, and appropriate solutions is crucial for effective maintenance and longevity. This guide covers everything from basic troubleshooting to advanced repairs, equipping you with the knowledge to maintain your car port’s structural integrity and aesthetic appeal.

The guide delves into identifying and addressing problems such as leaks, structural damage, and sagging, providing actionable steps and solutions. It also covers preventative measures to avoid future damage, ensuring the longevity of your car port investment. Whether you’re tackling a minor repair or a significant overhaul, this guide will provide a clear and concise approach.

Introduction to Car Ports

Car ports are essential structures for providing shade and protection for vehicles. They offer a cost-effective alternative to garages, shielding cars from the elements, including rain, sun, and snow. Their design allows for easy access to the vehicle while providing a degree of security. Various types of car ports are available, each with unique features and applications.Car ports are available in a wide range of materials, each with its own set of advantages and disadvantages.

Understanding these materials is crucial for selecting the right car port for your needs. Common materials include metal, wood, and vinyl, each offering distinct characteristics in terms of durability, aesthetics, and maintenance requirements. Size and dimensions of car ports are also critical considerations, impacting the vehicle they are designed to accommodate.

Car Port Materials

Different materials offer varying levels of durability, aesthetics, and maintenance requirements. The choice of material is influenced by factors like budget, desired lifespan, and aesthetic preferences.

| Material | Pros | Cons |

|---|---|---|

| Metal (Steel/Aluminum) | Durable, long-lasting, relatively low maintenance, aesthetically diverse with various finishes (e.g., galvanized, powder-coated), and often cost-effective in the long run. | Can be susceptible to rust if not properly treated, may require painting or other protective measures for extended life, and can sometimes have a less appealing aesthetic compared to wood or vinyl. |

| Wood | Natural, aesthetically pleasing, relatively easy to customize with different wood types, often a preferred choice for a traditional look, and can be easily installed by DIY enthusiasts. | Susceptible to rot, decay, and insect damage if not treated properly, requires more maintenance than metal, and may have a higher initial cost compared to metal. |

| Vinyl | Low maintenance, weather-resistant, and resistant to rot, decay, and insect damage, offering a clean, modern aesthetic. | Can be prone to fading or discoloration over time, may not be as durable as metal or wood, and can be more expensive than metal in some cases. |

Car Port Sizes and Dimensions

Proper sizing is essential for a car port to effectively accommodate the intended vehicle. Factors like the dimensions of the vehicle, the desired overhang, and local building codes must be considered. A car port that is too small will not provide adequate protection, while one that is too large will be an unnecessary expenditure of resources. Common sizes range from compact models for single cars to larger designs for multiple vehicles, with consideration for storage and access.

The overhang is also critical for protection from the elements, impacting the overall size and cost.

Car Port Styles

The style of car port influences its suitability for different properties and purposes. Different designs cater to various needs and preferences.

| Style | Description | Suitability |

|---|---|---|

| Cantilever | A single-sided car port that extends outward from a wall or post, offering a simple and effective design. | Suitable for areas with limited space or for projects that require a minimalist design. |

| Lean-to | A car port that is attached to an existing structure, such as a house or garage, offering a space-saving solution. | Ideal for adding extra coverage to an existing structure, minimizing footprint, and creating a seamless transition with an adjacent building. |

Identifying Common Car Port Problems

Car ports, while providing essential shade and protection for vehicles, are susceptible to various issues over time. Understanding these common problems and their causes is crucial for preventative maintenance and timely repairs, ensuring the longevity and functionality of your car port. Proper identification of problems allows for targeted solutions and avoids costly repairs down the road.Identifying the root causes of car port issues is key to implementing effective solutions.

This involves understanding how different factors, from installation errors to environmental stressors, can impact the structural integrity and performance of your car port. Early detection of these problems is vital to avoid significant damage and costly repairs.

Common Car Port Leaks

Car port leaks are a prevalent problem, often stemming from faulty roofing materials or improper sealing. These issues can lead to significant water damage to the vehicle and structural components of the car port itself. Various weather conditions can exacerbate these leaks, leading to mold growth and other long-term consequences. Pay close attention to areas where the roof meets the walls or supports.

- Poorly sealed joints between roofing panels can allow water to penetrate the structure.

- Damaged or missing flashing around windows or vents create entry points for water.

- Inadequate gutter systems can lead to water pooling and overflow, causing leaks.

Structural Damage in Car Ports

Structural damage is another frequent issue, often resulting from improper installation or prolonged exposure to harsh weather conditions. Recognizing the signs of structural problems is essential to prevent further damage and potential safety hazards. Observe the support beams and framework carefully for any signs of bending, warping, or cracking.

- Wind and snow loads can cause stress on the supports, leading to sagging or collapse.

- Poorly anchored posts or supports can result in movement or shifting, which could compromise the structural integrity.

- Repeated exposure to extreme temperatures can cause metal parts to expand or contract, potentially leading to stress fractures or other structural damage.

Sagging Car Ports

Sagging car ports are a common problem, particularly in older structures or those subjected to heavy snow loads. This often results in discomfort and potentially damages stored vehicles. The cause of sagging can vary from inadequate support systems to structural weakening due to weathering. The degree of sagging will often correlate with the severity of the cause.

- Insufficient support beams or posts can lead to a sagging roofline over time.

- Heavy snow accumulation can overload the structure, causing the roof to sag.

- Poorly maintained supports, including rust or rot, can reduce the structural capacity and lead to sagging.

Signs of Car Port Repair Needs

Early identification of car port problems is essential for timely repairs and prevents further damage. Pay attention to any signs of water damage, structural issues, or sagging. Examples include leaks, rusting metal, cracking or warping wood, and visible sagging. Prompt attention to these issues can significantly prolong the life of your car port.

- Leaks in the roof or walls can be a clear indication of potential water damage.

- Rust or rot on metal or wood components signifies deterioration and potential structural weakness.

- Sagging rooflines or distorted support beams indicate structural issues requiring attention.

Weather Conditions Impacting Car Ports

Different weather conditions can significantly impact the condition of car ports. Heavy snow loads can put tremendous stress on the structure, while intense winds can cause damage to the roofing or supports. Prolonged exposure to moisture can lead to rotting or corrosion.

- Heavy snowfall can overload the roof, causing sagging or structural failure.

- High winds can rip off roofing materials or damage support structures.

- Prolonged periods of rain or moisture can lead to rot, mold, and corrosion in wood or metal components.

Troubleshooting Table

| Problem | Cause | Solution |

|---|---|---|

| Leaks | Poorly sealed joints, damaged flashing, inadequate gutters | Reseal joints, repair flashing, install or repair gutters |

| Structural Damage | Poor installation, weather damage, improper maintenance | Reinforce supports, repair or replace damaged components, upgrade support systems |

| Sagging | Insufficient support, heavy snow load, weakened supports | Add additional supports, reinforce existing supports, remove excessive snow load, replace deteriorated components |

Basic Troubleshooting for Car Ports

Maintaining a car port involves more than just keeping it clean. Regular inspections and prompt fixes for minor issues can prevent significant damage and extend the life of your structure. Understanding basic troubleshooting techniques empowers you to address problems proactively, saving time and money in the long run.Proper maintenance ensures the structural integrity and longevity of your car port, protecting your vehicle and belongings.

This includes identifying and addressing potential issues before they escalate into major problems.

Basic Car Port Maintenance Procedures

Regular cleaning and inspections are crucial for preventing the accumulation of debris and identifying potential problems early. A clean car port allows for easier visual inspections, enabling the detection of damage or deterioration.

- Cleaning: Regular cleaning, such as sweeping or hosing down the structure, removes dirt, leaves, and other debris. This helps prevent the build-up of moisture and encourages the longevity of the car port.

- Inspection: A thorough visual inspection of the entire car port is essential. Look for signs of damage, such as cracks in the frame, warping of the support beams, or sagging of the roof.

Checking for Loose Screws and Bolts

Regularly checking for loose screws and bolts is vital for maintaining the structural integrity of the car port. Loose fasteners can lead to instability and potential collapse.

- Visual Inspection: Carefully examine all visible screws and bolts, paying particular attention to those located at the connections between structural components. Look for any signs of movement or play.

- Tactile Check: Gently try to move each screw or bolt with your fingers. If it moves significantly, it is loose and needs tightening.

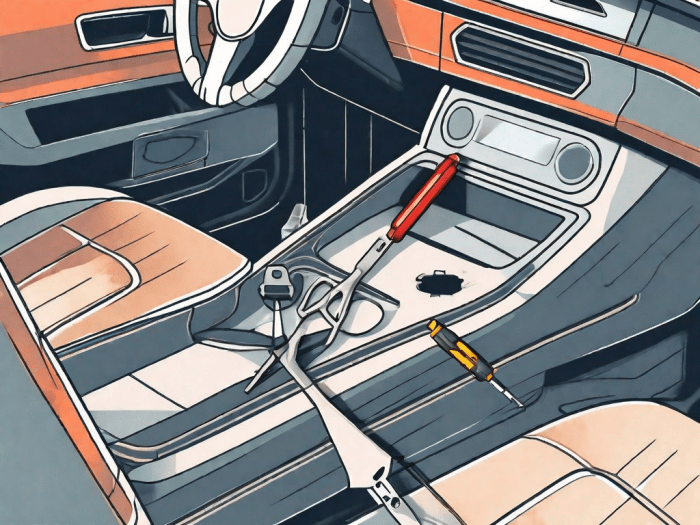

Tightening Loose Components

Appropriate tightening methods are essential to avoid damaging the fasteners or the car port’s components. Using the correct tools and applying the right amount of torque is critical.

- Use the Right Tools: Employ appropriate tools such as screwdrivers (Phillips or flathead, depending on the screw type) and a wrench or socket set for bolts. Ensure the correct size of the tool for the fastener is used to avoid damage.

- Appropriate Tightening: Tighten each screw or bolt until it is secure, but do not overtighten. Overtightening can strip the threads or damage the material. A slight resistance should be felt before the screw or bolt is fully tightened.

Inspecting for Water Damage, How to fix a car port

Identifying water damage early is crucial to prevent further deterioration of the car port. Water damage can weaken the structure and cause leaks.

- Check for Dripping: Inspect the roof and the walls of the car port for any signs of dripping water, especially after periods of heavy rainfall or snow melt. This could indicate a leak or a structural issue.

- Look for Moisture: Check for signs of water accumulation on the interior and exterior surfaces of the car port. Look for discoloration, mold, or mildew. Check for wet spots or areas that appear damp or unusually soggy.

- Examine the Drainage System: Ensure proper drainage around the car port perimeter. Clogged gutters or downspouts can lead to water accumulation and potential damage. Check the drainage system and clear any obstructions.

Tools Needed for Basic Car Port Maintenance

Having the right tools readily available simplifies the maintenance process. The specific tools needed depend on the particular issues being addressed.

- Screwdrivers (Phillips and flathead)

- Wrench or Socket Set

- Measuring Tape

- Level

- Cleaning Supplies (e.g., broom, hose, detergent)

- Safety Glasses

- Gloves

Fixing Minor Leaks

Addressing minor leaks promptly prevents further damage. The repair method depends on the location and cause of the leak.

- Caulk or Sealant: For small gaps or cracks, applying caulk or sealant can often stop minor leaks. Apply a bead of sealant along the damaged area, ensuring complete coverage. Let the sealant dry completely according to the manufacturer’s instructions.

- Repairing Damaged Panels: If the leak is caused by a damaged panel, replace the damaged panel with a new one, ensuring proper installation to prevent future leaks.

Fixing Specific Car Port Issues

Addressing issues with your car port requires a systematic approach, focusing on the specific problem areas. Proper repair techniques prevent further damage and ensure long-term structural integrity. A well-maintained car port provides essential protection for your vehicles and belongings.

Repairing a Sagging Car Port

Sagging car ports often stem from weakened support structures. A thorough inspection is crucial to identify the source of the sagging. Common causes include inadequate support beams, deteriorated anchoring, or settling ground. Reinforcing the existing structure or replacing components is necessary.

- Assess the cause: Determine if the sagging is due to structural weakness, ground settlement, or improper installation. This involves checking the condition of support beams, anchoring, and the ground beneath the car port. Visual inspection and careful measurements will help pinpoint the problem area.

- Reinforce support beams: Adding bracing or reinforcing existing beams with stronger materials is essential. Metal plates or additional support beams can effectively reinforce the structure, restoring its stability. Consider the weight of the car port and the expected load it will bear.

- Re-anchor the structure: If anchoring issues are the cause, reinforce or replace existing anchors with more robust ones. Ensure the anchors are properly embedded into the ground for maximum stability. Use concrete or other suitable materials for anchoring.

Fixing Damaged Framing

Damaged framing can compromise the overall integrity of the car port. Identifying the damaged sections and implementing appropriate repair techniques are critical. The type of wood or metal used in the framing and the extent of the damage will influence the chosen repair method.

- Assess the damage: Identify the location and extent of the damage. Note any rot, cracks, or structural weakness in the framing. Proper assessment determines the necessary repairs.

- Repair or replace damaged members: Depending on the severity, damaged framing members may require repair or replacement. For minor damage, patching, reinforcing, or using suitable wood fillers might suffice. For substantial damage, replacement with new, compatible materials is recommended.

- Secure connections: Ensure all connections between framing members are secure and properly aligned. Use appropriate fasteners and connectors to reinforce the connections. Ensure all fasteners are the correct size and type for the material.

Repairing or Replacing a Damaged Roof

A damaged car port roof can lead to leaks and further damage. Proper repair or replacement of the roof is crucial to maintaining the structural integrity and weather protection of the car port. The type of roofing material used (metal, composite, etc.) will guide the repair or replacement process.

- Assess the damage: Identify the source and extent of the roof damage. Look for cracks, holes, missing sections, or signs of water damage. Thorough inspection is vital to ensure the complete repair.

- Repair or replace damaged sections: Small tears or punctures might be repairable with patching materials. Large sections requiring replacement should be replaced with identical or compatible materials. Ensure the replacement is aligned with the existing structure.

- Seal the roof: After repairs, seal any gaps or openings to prevent further water infiltration. This is critical for maintaining the integrity of the roof.

Fixing Leaks in a Metal Car Port

Leaks in a metal car port often originate from imperfections in the metal sheets or the connections between them. Identifying and fixing the leak source is paramount. Use suitable sealants and repair methods to prevent water intrusion.

- Locate the leak: Carefully examine the metal sheets and connections for any visible signs of leaks. Use a spray bottle of water to identify the exact location of water penetration. This helps in concentrating repair efforts.

- Repair or replace damaged metal: If the leak is caused by a damaged section of metal, repair or replace the affected area with compatible material. Apply appropriate sealant or caulk to prevent further leaks. Use sealant that matches the material.

- Check and seal connections: Ensure all connections between metal sheets are properly sealed. Use appropriate sealant for metal to prevent water penetration through seams. Check for corrosion or damage at the joints.

Addressing Water Damage in the Frame

Water damage in the frame can lead to rot and structural failure. Addressing the water damage promptly is crucial to prevent further damage and maintain the structural integrity of the car port. Identifying the source of the water intrusion is the first step.

- Identify the source of water intrusion: Determine where the water is entering the frame. Look for leaks in the roof, damaged seals, or improper drainage. Identify the point of entry for concentrated efforts.

- Dry the affected area: Remove any standing water and thoroughly dry the damaged wood or metal components. Use fans or other drying methods to accelerate the process. Ensure the area is completely dry before any repair or replacement.

- Repair or replace damaged components: Repair or replace any damaged wood or metal components that have been affected by water. Use appropriate wood preservatives or sealants to prevent further rot and moisture damage.

Replacing Damaged Support Beams

Replacing damaged support beams involves careful assessment of the damage, selection of suitable replacement materials, and proper installation techniques. The type of beam, the load it carries, and the overall structure of the car port dictate the replacement process.

- Assess the damage and determine the type of replacement: Evaluate the extent of damage and the load capacity requirements. Determine if the replacement requires a similar or stronger material. Choose a beam that matches the original or improves the load-bearing capacity.

- Plan the replacement procedure: Account for existing infrastructure, space constraints, and structural support requirements. Create a detailed plan for the replacement, including the type of fasteners and connectors to be used. Account for any adjustments needed in the existing structure.

- Install the replacement beam: Ensure the new beam is properly aligned and secured to the existing structure. Use appropriate fasteners and connectors. Follow manufacturer instructions or structural engineering guidelines for installation. Double-check the support system for alignment.

Advanced Car Port Repairs

Addressing complex car port issues requires a systematic approach and a thorough understanding of the structure’s design and materials. This section delves into advanced repair techniques, from complete roof replacements to reinforcing the entire structure for enhanced stability. Proper execution of these procedures is crucial for maintaining the longevity and safety of your car port.

Replacing a Complete Roof System

Replacing a car port’s roof system is a significant undertaking, often requiring specialized tools and expertise. Careful planning and execution are vital to avoid further damage and ensure a secure, long-lasting replacement. Consider factors like the roof’s original design, the type of roofing material used, and local building codes. The process involves removing the old roofing material, inspecting the underlying structure for damage, and installing the new roof system according to manufacturer specifications.

Installing New Support Columns

Adding or replacing support columns is a critical structural repair. This often necessitates careful assessment of the existing foundation and structural integrity. The procedure involves removing the old columns, preparing the foundation for new posts, and installing the new columns with appropriate anchoring and bracing. Properly sized and anchored support columns are essential to prevent future structural issues and ensure the stability of the entire car port.

Reinforcing an Existing Car Port Structure

Reinforcing an existing car port structure involves enhancing its stability and load-bearing capacity. This can involve adding additional support beams, reinforcing existing columns with metal plates or braces, or utilizing specialized anchoring systems. Assessing the existing structure for weaknesses and vulnerabilities is crucial. This process is particularly important in areas prone to high winds or heavy snowfalls.

Repairing or Replacing Damaged Metal Components

Damaged metal components, such as rusted beams or sagging supports, need prompt attention. Identifying the extent of damage and choosing the right repair or replacement method is crucial. If the damage is extensive, replacement might be the best option. The choice depends on the severity of the damage and the overall structural integrity. Proper welding or fastening techniques are essential for a secure repair.

Restoring Aesthetic Appeal After Repairs

Repairs often leave visible marks or inconsistencies. Restoring the car port’s aesthetic appeal involves careful matching of materials and finishes to the original design. Painting, staining, or applying protective coatings can help restore the car port’s original appearance. Matching colors and textures to the existing structure is key for a seamless integration of the repairs.

Replacing the Roof of a Car Port: Step-by-Step Guide

| Step | Description | Tools |

|---|---|---|

| 1 | Remove the old roofing material, ensuring no damage to the underlying structure. | Safety equipment, roofing pry bar, utility knife, gloves |

| 2 | Inspect the existing frame for any damage or deterioration. Address any identified issues. | Measuring tape, screwdriver, flashlight |

| 3 | Prepare the new roof structure by cutting and assembling the required components. | Measuring tape, utility knife, scissors, screws, nails |

| 4 | Install the new roofing material according to manufacturer instructions. | Roofing nails, sealant, hammer, roofing tools |

| 5 | Secure all components and ensure proper drainage. | Roofing sealant, caulk gun, sealant |

| 6 | Clean up the work area and restore the surrounding area to its original condition. | Brooms, dustpans, cleaning supplies |

Prevention and Maintenance

Proactive measures are crucial for extending the lifespan and functionality of your car port. Proper maintenance not only prevents costly repairs but also ensures the safety and longevity of your structure. Ignoring preventative measures can lead to significant damage, including leaks, structural weakening, and aesthetic deterioration.Regular inspections and timely maintenance are key to a long-lasting car port. Addressing minor issues early can prevent them from escalating into major problems, saving you time and money in the long run.

This section Artikels preventative strategies, maintenance schedules, and essential materials to keep your car port in optimal condition.

Preventative Measures to Avoid Damage

Implementing preventative measures is vital to maintaining a car port’s structural integrity and aesthetic appeal. These strategies can significantly reduce the likelihood of costly repairs and ensure the longevity of your investment. Addressing potential issues before they become significant problems is a cornerstone of effective car port maintenance.

- Regular cleaning is essential. Remove debris, leaves, and other accumulated materials to prevent water buildup and potential rot. This simple task can significantly reduce the risk of structural damage.

- Inspect for signs of damage. Pay close attention to any cracks, loose fasteners, or signs of rust. Early detection of these issues can prevent more extensive damage.

- Protect from harsh weather. Use appropriate coverings or treatments to shield the car port from extreme temperatures, heavy rain, and strong winds. This proactive measure will help maintain the structure’s integrity.

Importance of Regular Inspections and Maintenance

Regular inspections and maintenance are critical for maintaining a car port’s structural integrity. Consistent checks can identify minor issues before they escalate into major problems. This proactive approach ensures that potential problems are caught early and addressed promptly, preventing significant damage and costly repairs.

- Early detection of problems is crucial. Addressing minor issues quickly can prevent them from developing into more substantial and expensive repairs. This proactive approach ensures the long-term stability and aesthetic appeal of your car port.

- Maintaining structural integrity is essential. Regular inspections help identify and address potential structural weaknesses, ensuring the car port can withstand environmental stresses over time. This preventive measure reduces the risk of collapse or damage from extreme weather events.

- Preserving the car port’s appearance is important. Routine maintenance prevents the accumulation of debris and damage, maintaining the car port’s aesthetic appeal. This contributes to the overall value and curb appeal of your property.

Routine Car Port Maintenance Schedule

A well-defined schedule ensures your car port remains in optimal condition. Consistency is key to avoiding significant damage.

| Month | Task |

|---|---|

| Spring | Thorough cleaning, checking for signs of damage (e.g., rust, cracks). |

| Summer | Regular cleaning, inspection for water damage, and checking for loose fasteners. |

| Fall | Thorough cleaning, checking for damage from falling leaves or debris, and protecting from potential winter weather. |

| Winter | Inspect for ice and snow accumulation. Protect from extreme cold and potential ice damage. |

Materials Needed for Routine Maintenance

A checklist of essential materials simplifies routine maintenance.

- Cleaning supplies (detergent, water hose, soft brush): For removing debris and dirt buildup.

- Screwdrivers and wrenches: For inspecting and tightening loose fasteners.

- Rust-resistant paint or sealant: For repairing or preventing rust formation.

- Roofing repair materials (if needed): For patching any holes or damaged areas.

Best Practices for Protecting from Harsh Weather

Protecting your car port from harsh weather conditions is essential for its longevity.

- Proper drainage is crucial. Ensure water flows away from the car port to prevent water damage and rot.

- Use protective coverings (e.g., tarps) during extreme weather events to shield the car port from wind and rain. This simple measure can prevent significant damage.

- Reinforce the structure if necessary. Bolstering the structure against high winds or other extreme weather conditions can prevent damage.

Maintaining Structural Integrity

Maintaining structural integrity is paramount for a car port’s long-term stability.

- Regular inspection of supports and fasteners is vital. Check for any signs of wear or damage. Prompt attention to these issues prevents structural collapse.

- Addressing any signs of settling or sagging is crucial. Addressing these issues immediately will prevent further damage to the car port.

- Using appropriate materials and techniques for repairs is essential. Proper materials and methods ensure the repair is durable and effective, preventing future problems.

Resources and Further Information

Finding reliable resources is crucial for effectively maintaining and repairing your car port. Comprehensive information allows you to make informed decisions, troubleshoot issues effectively, and prevent future problems. This section provides valuable resources, from reputable websites and articles to local contractors and safety precautions.

Reputable Resources for Car Port Repair and Maintenance

Numerous websites and articles offer valuable insights into car port maintenance and repair. These resources provide practical advice, detailed instructions, and real-world examples. For instance, researching online forums dedicated to DIY home improvement can be incredibly helpful, allowing you to connect with other homeowners facing similar challenges and gain valuable insights from their experiences. Local building supply stores can also provide helpful advice and support regarding materials and maintenance.

Helpful Articles and Videos on Car Port Repair

Numerous articles and videos provide step-by-step instructions and visual demonstrations for car port repair. These resources can be invaluable in tackling various maintenance and repair tasks. Look for resources with clear, concise explanations, high-quality images, or videos showcasing the process.

Contacting Local Contractors for Assistance

When tackling complex or challenging car port repair projects, seeking professional help from local contractors is essential. Contacting local contractors involves researching their experience and qualifications, ensuring they have a proven track record of successfully completing similar projects. Look for reviews and testimonials from previous clients to assess their reputation and reliability.

Companies Specializing in Car Port Repair

A list of companies specializing in car port repair can be found online through local business directories or online searches. These companies are equipped to handle various repair needs, from minor adjustments to major structural repairs. They can offer expert advice and provide solutions to specific challenges, such as material selection and weather resistance. Ensure the company has the necessary licenses and insurance.

Safety Precautions While Working on a Car Port

Proper safety precautions are essential during any car port repair or maintenance task. Always prioritize safety by wearing appropriate protective gear, such as safety glasses, gloves, and sturdy work boots. Ensure the work area is well-lit and clear of obstructions. If working at height, use proper fall protection measures. Avoid working alone when possible.

This reduces the risk of injuries and ensures that appropriate assistance is available in case of accidents.

Common Car Port Materials and Weather Resistance

| Material | Weather Resistance | Example |

|---|---|---|

| Steel | High resistance to rust and weathering, durable, but susceptible to dents. | Galvanized steel, powder-coated steel |

| Aluminum | Excellent resistance to rust and weathering, lightweight, but may be susceptible to scratches or dents. | Aluminum frames, aluminum composite panels |

| Wood | Requires regular maintenance and sealing to prevent rot and decay, susceptible to moisture damage. | Pressure-treated lumber, cedar wood |

| Vinyl | Durable and low maintenance, resists most weather conditions, but can be brittle in extreme cold. | Vinyl siding, vinyl roofing |

| Composite | High resistance to weather damage, low maintenance, but may be more expensive. | Fiber-cement panels, composite decking |

Outcome Summary

In conclusion, this guide has provided a comprehensive overview of car port repair, from initial identification of problems to advanced solutions and preventative measures. By understanding the potential issues, their causes, and the appropriate solutions, you can effectively maintain and repair your car port. The information presented equips you with the knowledge and tools to address various scenarios, ensuring the structural integrity and longevity of your car port.

Remember regular maintenance and proactive problem-solving are key to preserving its value.

FAQ Resource: How To Fix A Car Port

What are the common causes of car port sagging?

Sagging car ports can be caused by several factors, including inadequate support structures, improper installation, excessive weight, or settling of the ground. Weather damage, such as extreme temperature fluctuations, can also contribute to the problem.

How often should I inspect my car port for maintenance?

Regular inspections are crucial for preventing major problems. A thorough inspection should be conducted at least twice a year, or more frequently if exposed to harsh weather conditions. This includes checking for signs of damage, loose components, and any signs of water intrusion.

What are the different types of car port materials?

Common car port materials include metal, wood, and vinyl. Each material has its own advantages and disadvantages in terms of durability, cost, and aesthetic appeal. Metal is often durable but susceptible to rust, while wood offers a more natural look but requires more maintenance. Vinyl is a relatively low-maintenance option.

What are some basic tools needed for car port maintenance?

Basic tools for car port maintenance include screwdrivers, wrenches, a ladder, and safety glasses. Additional tools might be needed depending on the specific repair. It is crucial to prioritize safety when using tools.