How to fix a short circuit on a scooter? This guide walks you through identifying, understanding, and safely repairing short circuits on your scooter. We’ll cover everything from recognizing the tell-tale signs of a short to the proper repair techniques, and even preventative measures to keep your scooter running smoothly.

Scooter electrical systems can be tricky, but with the right knowledge and a methodical approach, you can tackle this common problem. We’ll break down the process step-by-step, making it easier to understand and execute.

Identifying a Short Circuit

A short circuit, a common electrical fault in scooters, occurs when the electrical current bypasses the intended circuit path. This unintended pathway, often involving a low-resistance connection, can lead to significant damage if not promptly identified and addressed. Understanding the telltale signs of a short circuit is crucial for preventing further harm and ensuring the scooter’s safety and longevity.

Signs and Symptoms of a Short Circuit

Short circuits manifest through a variety of symptoms, ranging from subtle indications to dramatic visual displays. These symptoms are often interconnected, and their presence can significantly aid in the diagnosis of the issue. Careful observation and analysis of the scooter’s behavior and physical condition are essential.

Visual Indicators of Short Circuits

Visual inspection plays a vital role in identifying potential short circuits. Look for signs of overheating and damage. Melted wires, often exhibiting a blackened or charred appearance, are a clear indication of excessive current flow. Scorched insulation or components, such as the plastic housings around electrical components, indicate that the current has exceeded safe operating levels. Unusual sparking, emanating from connections or components, is another alarming symptom.

This visible arc of electricity can result in localized damage.

Examples of Short Circuit Damage

A common scenario involves melted wires near the battery connections. The wires might appear visibly deformed and blackened, suggesting that excessive current has passed through them, causing localized heating. Another example includes a scorched connector block, where the heat generated by the short circuit has damaged the surrounding plastic or other insulating materials. Additionally, a significant amount of sparking emanating from the headlight or taillight assembly, along with a burnt smell, can indicate a short circuit in the lighting circuit.

Distinguishing Short Circuits from Other Electrical Problems

It’s essential to differentiate a short circuit from other electrical problems. Overloading the scooter’s electrical system can cause similar symptoms, but the underlying cause is different. A faulty component, such as a motor or controller, may also produce unusual sounds or performance issues. The key difference lies in the presence of excessive current flow and the subsequent damage caused by a short circuit.

Comparison Table: Short Circuit Indicators, How to fix a short circuit on a scooter

| Indicator | Visual | Audible | Performance |

|---|---|---|---|

| Short Circuit | Melted wires, scorched components, sparking | Loud crackling or popping sounds | Sudden power loss, flickering lights, erratic motor operation |

| Overloading | Overheating components, but not necessarily melting | No unusual sounds | Reduced performance, but generally consistent |

| Faulty Component | Possible localized damage (depending on the component) | Unusual grinding or whirring sounds | Specific malfunctioning of a component (e.g., headlight not functioning) |

The table above summarizes the differences in indicators, providing a clear comparison between short circuits, electrical overload, and faulty components. This table serves as a useful diagnostic tool for identifying the root cause of electrical issues.

Understanding Scooter Electrical Systems

The electric scooter, a marvel of modern engineering, relies on a complex interplay of electrical components to propel its rider. Understanding these components and their interactions is crucial for troubleshooting issues, including identifying and resolving short circuits. This section delves into the fundamental electrical systems of a typical scooter, providing insights into wiring, batteries, and motors.A short circuit, often the culprit behind scooter malfunctions, disrupts the intended flow of electricity.

By grasping the fundamentals of these systems, you’ll be better equipped to diagnose and rectify such problems, ensuring the safe and efficient operation of your scooter.

Fundamental Electrical Components

The electric scooter’s electrical system comprises several critical components, each playing a vital role in its functionality. The heart of the system is the battery, which provides the electrical energy necessary for operation. The motor converts this electrical energy into mechanical energy, propelling the scooter. The wiring system acts as the conduit, transmitting electrical current between the battery, motor, and other components.

Scooter Wiring Diagrams

Different scooter models employ various wiring configurations, each with its own nuances. A single-phase system utilizes a single electrical pathway, while a three-phase system divides the current into three separate phases, optimizing power delivery and motor control. Understanding the specific wiring diagram of your scooter model is essential for accurate troubleshooting.

Battery Systems

Scooter batteries are typically lithium-ion, characterized by their high energy density and relatively long lifespan. These batteries are susceptible to damage from overcharging, over-discharging, and physical stress. Proper charging procedures and maintenance are crucial to maximize battery lifespan.

Motor Systems

Electric motors in scooters convert electrical energy to mechanical energy, powering the wheels. Understanding the motor’s electrical specifications, such as voltage and current ratings, is vital for safe operation and troubleshooting. Motor windings, crucial for current flow, can be damaged by excessive current, a common occurrence in short circuits.

Checking Wiring Continuity

Ensuring the proper flow of electricity in a scooter circuit is paramount. A broken or shorted wire can disrupt the intended current flow, leading to malfunctions. This procedure Artikels how to check the continuity of wires:

- Gather the necessary tools, including a multimeter, wire strippers, and safety glasses. Safety precautions are critical when working with electrical systems.

- Identify the wires to be tested. Carefully locate the specific wires you need to examine. Refer to the scooter’s wiring diagram for accurate identification.

- Prepare the multimeter for continuity testing. Set the multimeter to its continuity test mode. A beep or a visual indication on the display will confirm a complete circuit.

- Test each wire. Carefully strip the insulation from the ends of the wires. Connect the multimeter probes to the exposed wire ends. If the circuit is intact, the multimeter should indicate continuity.

- Document the results. Record the findings of each wire continuity test. This record will prove invaluable for diagnosing problems.

Flow of Electricity in a Scooter Circuit

The electrical flow in a scooter circuit follows a specific pathway. The battery supplies electrical energy. This energy travels through the wiring to the motor, driving the motor’s rotation. The motor converts this electrical energy into mechanical energy, propelling the scooter. A short circuit disrupts this path, causing a surge in current.

Troubleshooting

Troubleshooting is often necessary in electric scooters. A multimeter, an essential tool, is used to measure the electrical characteristics of the circuit, helping to isolate the source of the problem. The wiring diagram is crucial for understanding the scooter’s electrical system.

Safety Precautions

Working on scooter electrical systems requires meticulous attention to safety. Neglecting these precautions can lead to serious injury from electrical shocks, burns, or even fire. Understanding the inherent dangers and employing appropriate safety measures is paramount for a successful and safe repair process. This section Artikels crucial safety steps to ensure a secure and controlled environment during scooter electrical system maintenance.

Disconnecting the Battery

Properly disconnecting the battery is the single most important safety step. A scooter’s electrical system, though seemingly simple, houses stored electrical energy within the battery. Failure to disconnect it can result in a hazardous electrical shock. This stored energy can cause a significant current flow even when the scooter is seemingly off. This stored energy poses a significant risk, as a brief connection to a component could still deliver a harmful shock.

Always refer to the scooter’s owner’s manual for the specific battery disconnection procedure.

Electrical Tool and Component Handling

Handling electrical tools and components demands utmost care. Always inspect tools for damage, ensuring insulation integrity. Damaged insulation compromises safety, increasing the risk of electrical shock. Improper handling can lead to short circuits or unintended connections, which can result in damage to the scooter’s electrical system or even cause a fire. Always use insulated tools and gloves when working with electrical components to avoid direct contact with energized wires.

Essential Safety Equipment

Ensuring the use of appropriate safety equipment is crucial. This includes safety glasses to protect eyes from flying debris or sparks, and work gloves to prevent contact with potentially hazardous components. A fire extinguisher should be readily available to address any potential electrical fires. A properly functioning fire extinguisher can be a life-saver during an emergency.

- Safety Glasses: Protect your eyes from flying debris, sparks, or potential splashes of corrosive fluids during component removal or repair.

- Insulated Gloves: Protect your hands from electrical shocks, especially when working with live wires. Ensure the gloves are appropriate for the voltage level.

- Work Gloves: Protect your hands from cuts, scrapes, or abrasions from sharp edges or metal parts during disassembly.

- Fire Extinguisher: Have a readily accessible fire extinguisher rated for electrical fires. This equipment is vital to contain any electrical fire.

- Insulated Tool Kit: Use tools specifically designed for electrical work, featuring insulated handles. This crucial safety measure reduces the risk of electrical shock.

Grounding

Grounding is an essential safety precaution. This involves connecting a conductive part of the scooter to the earth’s ground, providing a safe path for any stray current. This technique helps prevent electrical shocks by ensuring that any accidental current leakage has a direct path to the earth. This significantly reduces the potential for electrical hazards during maintenance.

Troubleshooting Short Circuits

Unveiling the electrical intricacies of a scooter, especially when encountering a short circuit, requires a methodical approach. Short circuits, a common electrical fault, occur when an unintended conductive path forms between two points with a voltage difference. This bypasses the intended circuit, leading to potentially damaging consequences. Understanding the common causes, locations, and troubleshooting procedures is paramount to restoring the scooter’s functionality and preventing further damage.Pinpointing the source of a short circuit necessitates a systematic examination of the scooter’s electrical components.

This process involves careful observation, measurement, and isolation techniques to identify the faulty connection. By understanding the electrical pathways and potential weak points, the technician can effectively pinpoint the source of the problem and restore the scooter’s operational efficiency.

Common Causes of Short Circuits

A variety of factors can contribute to short circuits in scooter electrical systems. These issues range from simple wire damage to more complex problems involving component failures.

- Damaged wiring: Physical damage to the wiring harness, such as cuts, abrasions, or kinks, can create a direct connection between wires, leading to a short circuit. This is particularly prevalent in areas subjected to stress, like bends and corners of the scooter’s frame.

- Corrosion: Accumulation of corrosion on terminals or connectors can reduce insulation and cause a short circuit. Moisture and salt are common contributors to this issue, particularly in environments with high humidity or exposure to road salt.

- Faulty components: Internal faults within components like the motor controller, the battery management system, or the headlight can generate a short circuit. Component failures can be caused by overheating, manufacturing defects, or prolonged use.

- Improper installation: Poorly secured connections, incorrect wiring, or improper component mounting can create a conductive path, resulting in a short circuit. This can happen if wires are not properly soldered, crimped, or secured in their designated locations.

- External interference: Foreign objects, like metal debris or water ingress, can inadvertently create a conductive path within the scooter’s electrical system. This can happen in scooters that have exposed wiring.

Potential Causes by Location

The location of a short circuit can significantly influence the troubleshooting process. Understanding potential problem areas allows for a more focused and efficient diagnostic approach.

| Location | Potential Causes |

|---|---|

| Wiring Harness | Damaged wires, corroded terminals, chafing against metal components, improper wire connections, loose or frayed insulation. |

| Battery Terminals | Corrosion on terminals, loose connections, damaged battery terminals, improper battery connections. |

| Motor Controller | Internal component failure, overheating, excessive current draw, component damage. |

| Electrical Connectors | Oxidized contacts, damaged connectors, loose connections, insufficient insulation. |

| Lighting System | Faulty bulbs, broken wire connections, excessive voltage fluctuations, damaged light housings. |

Troubleshooting Procedure

A systematic approach to troubleshooting short circuits is crucial. This involves progressively isolating sections of the electrical system to pinpoint the faulty component.

- Initial Inspection: Visually inspect all wiring harnesses, connectors, and terminals for signs of damage, corrosion, or improper connections. Look for any visible signs of overheating.

- Voltage Measurement: Use a multimeter to measure the voltage across the battery terminals. This will help determine if the battery is supplying power and if the system is receiving the correct voltage. This confirms the power source and the initial condition.

- Circuit Isolation: Disconnect the components one by one to isolate the affected section of the circuit. Start with the most accessible components and systematically eliminate potential problem areas. Carefully document the steps.

- Continuity Check: Use a multimeter to check for continuity in the wires and connectors within the isolated section. This identifies any direct connection between wires that might cause the short circuit. Ensure the scooter is off and the battery is disconnected before proceeding.

- Component Replacement: If a specific component is identified as the cause, replace it with a new, identical component. Follow the manufacturer’s guidelines to ensure proper installation.

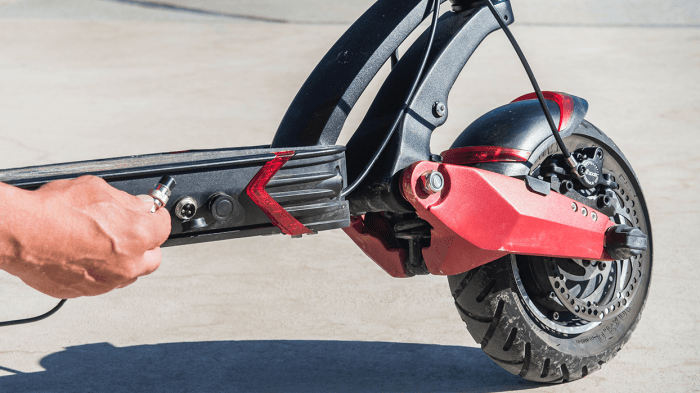

Repairing a Short Circuit

Unearthing the electrical fault within a scooter’s system, a short circuit, requires a methodical approach, encompassing careful diagnosis, safe procedures, and proficient repair techniques. Understanding the nature of the short circuit and the scooter’s electrical layout is crucial for successful repair. A poorly executed repair can lead to further damage or even safety hazards. Thoroughness and attention to detail are paramount in this process.

Methods for Repairing Damaged Wires

Identifying and addressing damaged wires is a critical step in short circuit repair. Different repair methods exist, each with its own set of advantages and disadvantages. The choice of method depends on the extent of the damage and the specific components involved.

- Splicing: This technique involves joining severed wires by carefully stripping the insulation, aligning the conductors, and securely fastening them together. Properly performed splicing can restore the electrical continuity of the circuit, but it requires meticulous attention to detail to ensure a strong and reliable connection. A poor splice can lead to further problems, including increased resistance and the risk of overheating.

- Replacement: In cases of significant wire damage, or when a splice is deemed inadequate, replacement is often the preferred option. This entails removing the damaged wire section and installing a new, identical one. This method ensures a reliable and consistent electrical path, eliminating the potential for future issues. The cost of replacement can vary depending on the wire’s length and the specific component involved.

It often involves more time compared to splicing, but it’s a safer and more durable solution for severe damage.

Soldering and Insulation Techniques

Proper soldering and insulation are crucial for achieving a robust and safe repair. These techniques ensure a reliable connection and prevent further damage or electrical hazards.

- Soldering: Soldering creates a strong, permanent connection between wires. The process involves applying solder to the exposed copper conductors of the wires to create a robust joint. Correct soldering temperature and application are essential to prevent damage to the surrounding components. Using the appropriate flux is vital for achieving a clean and efficient solder joint.

Overheating can lead to damage to the component and compromise the repair.

- Insulation: Insulating the repaired connections is equally important. A poor insulation job can lead to a recurrence of the short circuit. The type of insulation used should be compatible with the operating voltage and environmental conditions. Various insulation materials exist, ranging from heat-shrink tubing to electrical tape. Using the correct insulation material is critical to ensure the longevity and safety of the repair.

Comparison of Repair Methods

A comparison of repair methods should consider cost, complexity, and potential risks. The optimal method depends on the specific situation and the resources available.

| Repair Method | Cost | Complexity | Potential Risks |

|---|---|---|---|

| Splicing | Generally lower | Moderate | Risk of weak connection, overheating if not properly executed |

| Replacement | Higher | High | Requires more time and potentially more parts, but eliminates long-term risks |

A well-executed repair, regardless of the method, prioritizes safety and the longevity of the scooter’s electrical system.

Preventing Future Short Circuits

A recurring short circuit on your scooter can be frustrating and potentially dangerous. Understanding the root causes and implementing preventive measures is crucial for maintaining a safe and reliable electrical system. This section details strategies to mitigate the risk of future short circuits, emphasizing the importance of proactive maintenance and identifying potential hazards.Electrical systems, while designed to withstand certain stresses, are susceptible to damage from moisture, mechanical stress, and improper handling.

Proactive measures can significantly reduce the chance of encountering these issues. Careful attention to detail and a proactive approach to maintenance will be crucial in preserving your scooter’s electrical integrity.

Moisture Management

Proper moisture management is paramount to preventing short circuits. Moisture can create conductive pathways, leading to unexpected electrical flow. Water intrusion, whether from rain, spills, or condensation, poses a significant risk. Regular inspections for signs of water damage are essential.

- Regularly check the scooter’s electrical components for signs of water intrusion, such as rust, corrosion, or dampness. Inspect connectors, wiring harnesses, and the battery compartment for any signs of liquid damage.

- Park your scooter in a sheltered area whenever possible to minimize exposure to rain and moisture.

- If your scooter experiences a significant rain exposure, immediately inspect all electrical connections and components for damage. Dry thoroughly using a clean, absorbent cloth.

- Avoid parking in low-lying areas or locations prone to flooding.

Mechanical Integrity Checks

Mechanical damage to electrical components is another significant contributor to short circuits. Physical stress on wiring, connectors, or the battery can compromise their integrity. This can lead to exposed wires, frayed insulation, or damaged terminals.

- Regularly inspect the scooter’s wiring for any signs of damage, such as fraying, kinking, or cuts. Replace any damaged wires immediately to prevent short circuits.

- Ensure all electrical connections are tight and secure. Loose connections can generate heat and eventually lead to a short circuit.

- Examine the battery terminals for corrosion or damage. Corrosion can reduce the contact area and increase resistance, leading to overheating and potential short circuits. Clean and tighten terminals as needed.

- Inspect the scooter for any signs of physical damage, such as dropped components or parts that may have contacted the electrical system. Look for damage to the scooter’s frame that could have caused damage to internal wiring.

Regular Electrical Inspections

A crucial step in preventing future short circuits is implementing a regular inspection schedule for the scooter’s electrical system. This involves proactive checks to identify potential problems before they escalate.

- Visual Inspection: Regularly check all electrical components for visible damage, corrosion, or signs of moisture. This includes the battery, wiring, connectors, and any other exposed electrical parts. Look for frayed wires, loose connections, and any signs of water intrusion.

- Continuity Test: Use a multimeter to test the continuity of the wiring. This helps identify any breaks or shorts in the circuit. A simple continuity test can reveal hidden problems that visual inspection may miss.

- Resistance Check: Measure the resistance of critical components, such as the battery and various electrical circuits. This helps determine if any component is exhibiting excessive resistance, a potential sign of degradation or damage.

- Frequency: Establish a regular schedule for electrical inspections, perhaps weekly or monthly depending on the scooter’s usage. Frequent inspections are crucial to catch problems early.

Illustrative Examples

Imagine a meticulously crafted scooter, a symphony of moving parts, powered by electricity. A short circuit, however, can disrupt this harmony, leading to unexpected malfunctions and potentially hazardous situations. Understanding these scenarios is crucial for safe scooter maintenance and repair.A short circuit, in essence, is an unintended connection between two points in a circuit that are not supposed to be directly connected.

This bypasses the intended path, often leading to overheating and damage. The electrical current, instead of flowing through the designed pathways, takes the easier, shorter route, resulting in potentially damaging consequences.

Visual Representation of a Short Circuit

A typical scooter electrical system comprises a battery, a motor controller, a motor, lights, and various wires connecting these components. A short circuit occurs when two wires, or a wire and a metal frame part, touch, creating a direct path for the current to flow. This unintended connection is highlighted in the illustration below.[Visual description: A diagram of a scooter electrical system.

The diagram shows the battery, motor controller, motor, headlights, and taillights connected by wires. A highlighted section of the diagram illustrates two wires touching each other, creating a short circuit. The touching wires are colored red to indicate the short circuit.]

Impact on Scooter Components

Short circuits can severely impact different scooter components. The motor, the heart of the scooter’s propulsion system, can overheat and potentially fail due to the excessive current flow. The battery, the energy source, may also overheat and suffer damage, potentially leading to a fire hazard. Lights, which use smaller currents, might experience an immediate surge of current, causing them to burn out or malfunction.

The scooter’s electronics, such as the motor controller, are also vulnerable, and may experience damage from the sudden surge.

Scenarios and Potential Solutions

| Scenario | Potential Cause | Potential Impact | Potential Solutions ||—————————————-|—————————————————|—————————————————-|—————————————————|| Lights flicker and then stop working | Damaged wiring, loose connections, or a short circuit | Lights malfunction, potentially leading to impaired visibility.

| Inspect and repair the damaged wiring, tighten loose connections, and identify and fix the short circuit. || Motor makes a loud noise and stalls | Short circuit in the motor windings, damaged wiring | Motor overheating, failure, and potential damage | Identify the short circuit, repair the damaged wiring, and potentially replace the motor windings. || Battery gets extremely hot | Internal short circuit in the battery, external short | Risk of fire, battery damage, and scooter damage | Replace the battery, check for external shorts, and potentially contact a professional.

|| Scooter won’t start at all | Short circuit in the motor controller, battery issues | Scooter won’t operate, potentially causing inconvenience. | Check the motor controller for damage, check the battery’s voltage, and ensure no external shorts exist. |

Proper Wiring Techniques to Prevent Short Circuits

Ensuring proper wiring techniques is paramount to prevent short circuits. Careful insulation and secure connections are essential. Using appropriate wire gauges for the intended current, and using connectors designed for the specific application, are crucial steps. Crimping connectors properly, using heat shrink tubing, and keeping wires neatly organized can also contribute to preventing short circuits.[Visual description: A series of images showcasing proper wiring techniques.

The first image depicts correctly crimped connectors, highlighting the importance of secure connections. The second image shows the use of heat shrink tubing to insulate wires, preventing unintended contact. The third image displays neat and organized wiring, emphasizing the importance of cable management.]

Proper wiring, meticulous insulation, and secure connections are the cornerstones of preventing short circuits.

Wrap-Up

Fixing a short circuit on your scooter is achievable with the right steps. By understanding the electrical system, taking safety precautions, and systematically troubleshooting, you can identify and resolve the issue. Remember, prevention is key, so regularly inspecting your scooter’s electrical components can help avoid future problems. With a little know-how, you can keep your scooter running smoothly and safely.

FAQ Overview: How To Fix A Short Circuit On A Scooter

What are some common causes of short circuits on scooters?

Damaged wires, loose connections, moisture ingress, and mechanical stress (like a wire rubbing against a metal part) are common causes. A faulty battery can also contribute.

How can I prevent future short circuits?

Regular inspections, keeping the scooter dry, and ensuring secure connections are essential preventative measures. Using proper wiring techniques and protecting wires from damage also helps.

What safety equipment should I use when working on a scooter’s electrical system?

Safety glasses, gloves, and a non-conductive work surface are essential. Always disconnect the battery before working on any electrical components.

What are the visual signs of a short circuit?

Melted wires, scorched components, unusual sparking, and a burning smell are all visual signs of a short circuit. Performance issues, like the scooter not starting or unusual noises, can also be indicators.