How to install a leveling kit is a crucial process for modifying vehicle suspension. This comprehensive guide delves into the intricacies of installing leveling kits, covering everything from selecting the right kit to performing the installation safely and effectively. Understanding vehicle compatibility, meticulous preparation, and precise installation procedures are vital for achieving optimal results and maintaining the vehicle’s integrity.

The guide also addresses common troubleshooting steps and essential safety precautions.

From initial considerations like choosing the appropriate leveling kit type to the final post-installation checks, this guide offers a detailed roadmap for successful installation. The various aspects, including installation methods, safety measures, and potential issues, are explored in depth, ensuring a comprehensive understanding for both novice and experienced DIY enthusiasts.

Introduction to Leveling Kits

A leveling kit is a suspension modification that raises the vehicle’s ride height. This modification is frequently employed to improve vehicle appearance and handling, but also for accommodating larger tires and improving ground clearance. It’s a popular aftermarket upgrade for off-road vehicles, trucks, and SUVs.Leveling kits are available in various designs, each with its own advantages and disadvantages.

Understanding the different types and their implications is crucial for making an informed decision. This section will Artikel the different types, their benefits, and drawbacks, and provide a comparison table to aid your selection.

Types of Leveling Kits

Leveling kits primarily come in two major categories: coil spring and air suspension. Coil spring kits are more common and generally more affordable. Air suspension systems, on the other hand, offer more versatility and adjustable ride height, but they come with a higher price tag.

Coil Spring Leveling Kits

Coil spring leveling kits are the most common type. They replace the existing coil springs with modified springs that increase the ride height. This modification is usually achieved by utilizing longer springs or specialized spring packages. These modifications often maintain a relatively smooth ride and handle well on the road, while also offering improved ground clearance.

Air Suspension Leveling Kits

Air suspension leveling kits utilize an air compressor and a system of air bags to control the vehicle’s ride height. This provides more flexibility, allowing for customized ride height adjustments based on the terrain or the driver’s preference. However, air suspension systems require more complex maintenance, often requiring specific tools and procedures, and can be more costly to install and maintain.

Benefits of Leveling Kits

Leveling kits offer several advantages. Increased ground clearance is a primary benefit, allowing for better approach and departure angles, making the vehicle more capable for off-road driving. Improved tire clearance also permits the installation of larger tires and wheels, enhancing the vehicle’s appearance and performance. Additionally, leveling kits can improve the vehicle’s handling and stability.

Drawbacks of Leveling Kits

While leveling kits provide several benefits, they also come with potential drawbacks. Increased ride height can affect the vehicle’s handling and ride quality, making it feel slightly bouncy on some surfaces. Furthermore, some leveling kits might require modifications to other suspension components, potentially increasing the cost and complexity of the upgrade.

Comparison Table of Leveling Kit Types

| Type | Pros | Cons | Recommended Vehicles |

|---|---|---|---|

| Coil Spring | Generally affordable, relatively simple to install, smooth ride on the road | Limited adjustability, potential impact on ride quality on some surfaces | Trucks, SUVs, Jeeps (often with a good suspension system to start with) |

| Air Suspension | Highly customizable ride height, smoother ride, better handling in various conditions | Higher installation and maintenance costs, more complex setup | Luxury SUVs, performance trucks, vehicles requiring frequent height adjustment (like those in specific off-road competitions) |

Vehicle Compatibility

Choosing the right leveling kit for your vehicle is crucial for a smooth and safe installation. A poorly matched kit can lead to issues like uneven ride quality, suspension problems, and potential damage to your vehicle’s components. Understanding vehicle compatibility factors is vital to ensuring a successful upgrade.Properly researched compatibility is paramount. Buying a leveling kit without verifying its suitability for your specific vehicle model and year can lead to disappointment and potentially costly repairs.

A precise fit ensures the kit functions as intended and doesn’t introduce unforeseen issues.

Factors Determining Compatibility

Several factors determine if a leveling kit will work seamlessly with your vehicle. These include the vehicle’s make, model, and year, as well as its specific suspension configuration. Older models, for example, might have different suspension designs compared to newer models. The type of springs and shock absorbers also plays a role. Compatibility isn’t solely about the vehicle’s size but also the specific technical components.

Importance of Researching Compatibility

Thorough research before purchasing a leveling kit is essential to avoid costly mistakes. This includes checking for compatibility information from reputable sources, comparing different leveling kit options, and ensuring the kit aligns with your vehicle’s specific requirements. Skipping this step can lead to issues with installation, performance, and even potential damage to your vehicle. It is not worth the risk.

Finding Compatibility Information

Discovering compatibility information for your specific vehicle is achievable through various channels. Manufacturers’ websites often provide detailed specifications, compatibility charts, and FAQs related to their leveling kits. Online forums dedicated to off-roading and vehicle modifications can also offer valuable insights from other users with similar vehicles. Reading reviews and seeking expert advice from reputable mechanics or suspension specialists can also provide crucial information.

Online retailers and installers often provide compatibility guides.

Common Vehicle Compatibility Table

| Make | Model | Year Range | Leveling Kit Recommendations |

|---|---|---|---|

| Toyota | Tacoma | 2016-2023 | Rough Country, ReadyLift, ReadyLIFT |

| Jeep | Wrangler | 2018-2023 | OME, BDS, Icon |

| Ford | F-150 | 2015-2020 | Bilstein, Icon, Fox |

| Nissan | Titan | 2017-2022 | Pro Comp, Fabtech, Rough Country |

Note: This table is not exhaustive and serves as an example. Always verify compatibility with the manufacturer’s specifications for your specific vehicle and leveling kit.

Installation Preparation

Proper preparation is paramount for a successful leveling kit installation. A well-planned approach minimizes potential issues, saves time, and ensures a professional outcome. Thorough preparation encompasses gathering the necessary tools and parts, meticulously inspecting the vehicle, and strategizing the installation process. This proactive step significantly reduces the risk of errors and ensures the leveling kit performs as intended.

Essential Tools and Equipment

The installation process necessitates a diverse range of tools. Having the right tools ensures efficiency and minimizes the risk of damage. This careful selection avoids the frustration of needing to acquire tools mid-installation. Critical tools include but are not limited to:

- Sockets and wrenches: A comprehensive set of sockets and wrenches in various sizes is essential for disassembling and reassembling components. Different sizes are required for various nuts and bolts, ensuring proper fitment and torque.

- Torque wrench: Precise torque is critical for securing bolts and nuts. Using a torque wrench ensures consistent tightening, preventing damage to components or threads. This critical step is crucial for maintaining the vehicle’s structural integrity.

- Jack stands: Adequate jack stands are imperative for supporting the vehicle safely during the installation process. Using jack stands ensures the vehicle is securely supported and prevents any potential accidents.

- Jack: A jack is needed to lift the vehicle for access to undercarriage components. Proper jack selection, according to vehicle weight and specifications, is critical for safe lifting.

- Safety equipment: Gloves, safety glasses, and a work apron are crucial for safety. Protecting yourself from potential hazards during the installation process is a vital precaution.

Gathering Necessary Parts

Careful review of the leveling kit components ensures all necessary parts are included and accounted for. Mismatched parts can lead to installation problems, which can be time-consuming and costly to rectify. A thorough checklist will help prevent any omissions. It’s vital to have all parts on hand before starting.

- Leveling kit components: Ensure all components of the leveling kit are present. This includes springs, shocks, brackets, and any necessary hardware.

- Installation manual: Refer to the manufacturer’s instructions for specific installation steps and required parts. The manual will guide the process step-by-step and detail crucial safety considerations.

- Optional accessories: If using additional accessories, such as spacers or other custom parts, verify they are compatible with the leveling kit and the vehicle.

Vehicle Preparation

Proper vehicle preparation before installation minimizes potential issues during the process. A well-prepared vehicle reduces the risk of damage and ensures a smoother installation. This detailed preparation minimizes stress and ensures a professional outcome.

- Gather all tools and parts: Ensure all necessary tools and parts are collected and organized before starting the installation.

- Inspect the vehicle: Carefully inspect the vehicle’s undercarriage for any existing damage or wear. Document any pre-existing issues, which will help with any future repairs.

- Clean the undercarriage: Clean the undercarriage to improve access and visibility. Removing dirt and debris helps with better handling of components.

- Document existing condition: Document the vehicle’s current condition with photos or videos. This will serve as a baseline for comparison post-installation.

Pre-Installation Checklist

A pre-installation checklist ensures all necessary steps are taken. A well-structured checklist helps in avoiding any potential issues. This comprehensive checklist helps in minimizing mistakes and maximizes efficiency.

| Step | Action |

|---|---|

| 1 | Gather all tools and parts. |

| 2 | Inspect the vehicle’s undercarriage for damage. |

| 3 | Clean the undercarriage. |

| 4 | Document the vehicle’s current condition. |

| 5 | Review installation manual. |

Installation Procedures

Installing a leveling kit is a significant undertaking that requires careful attention to detail and adherence to safety protocols. Improper installation can lead to compromised vehicle handling, premature component wear, and even safety hazards. This section details the step-by-step procedures for installing a leveling kit, encompassing both DIY and professional approaches, and emphasizes the importance of following the manufacturer’s instructions.

Methods of Installation

Different methods for installing leveling kits exist, each with its own set of advantages and considerations. A crucial factor is the level of experience and tools available to the installer.

- DIY Installation: This method allows for cost savings and a greater degree of personalization. However, it demands a thorough understanding of the vehicle’s mechanical components and a familiarity with automotive tools and techniques. Thorough research and preparation are vital before embarking on a DIY leveling kit installation.

- Professional Installation: A professional installation ensures a higher quality of work, minimizes the risk of errors, and utilizes specialized equipment. This method typically comes at a higher cost but offers peace of mind regarding the integrity and longevity of the installation.

Significance of Manufacturer’s Instructions

Adherence to the manufacturer’s instructions is paramount for ensuring a safe, effective, and reliable leveling kit installation. The instructions provide specific procedures, torque specifications, and safety precautions tailored to the specific vehicle and leveling kit model. Deviation from these instructions can lead to unexpected problems, including but not limited to: component damage, compromised vehicle performance, and potential safety hazards.

Coil Spring Leveling Kit Installation Procedure

This table Artikels a typical step-by-step procedure for installing a coil spring leveling kit. It is crucial to understand that this is a general guide; specific procedures may vary based on the particular vehicle and leveling kit model. Always consult the manufacturer’s instructions for accurate and detailed guidance.

| Step | Description | Tools Required | Safety Precautions |

|---|---|---|---|

| 1 | Gather all necessary tools and components. Ensure all necessary parts are present, and the tools are in good working order. | Leveling kit components, socket set, wrench set, jack stands, jack, etc. | Wear appropriate safety gear (safety glasses, gloves, etc.). Work in a well-lit and safe area. Ensure adequate ventilation if working with chemicals. |

| 2 | Prepare the vehicle for installation by ensuring it is securely supported on jack stands. Disconnect the battery to avoid electrical hazards. | Jack stands, jack, battery disconnect tools. | Verify jack stands are stable and rated for the vehicle’s weight. Never work under a vehicle supported by a jack alone. |

| 3 | Remove the existing coil springs. Carefully follow the manufacturer’s instructions for disassembly. | Socket set, wrench set, spring compressor (if needed). | Use caution when handling springs. They may be under tension and could cause injury. Ensure the springs are properly supported during removal. |

| 4 | Install the new leveling kit components, including the new coil springs. Tighten all bolts and nuts to the manufacturer’s specifications. | Torque wrench, socket set, wrench set. | Use a torque wrench to ensure fasteners are tightened to the correct specifications. Never over-tighten fasteners. |

| 5 | Lower the vehicle and reassemble all components. | Jack, jack stands. | Lower the vehicle slowly and evenly. Ensure all components are securely in place. |

| 6 | Verify the vehicle’s level. Adjust as needed, if necessary, to achieve the desired level. | Leveling tool, measuring tape. | Work in a safe area, free from obstructions. |

| 7 | Conduct a thorough check of the vehicle for any signs of damage or misalignment. | Visual inspection. | Inspect all components for damage. |

After Installation

Congratulations on completing your leveling kit installation! Proper post-installation checks are crucial to ensure the safety and longevity of your vehicle’s suspension system. These steps guarantee your vehicle performs as intended and maintains optimal handling characteristics. Following these guidelines will help you avoid potential issues and enjoy the benefits of your new suspension setup.Careful attention to post-installation procedures is essential to maximize the performance and safety of your vehicle.

A well-maintained and aligned suspension system directly impacts driving stability, ride comfort, and the overall life of your vehicle.

Post-Installation Checks, How to install a leveling kit

Thorough post-installation checks ensure the leveling kit is installed correctly. This helps prevent potential issues like premature wear, misalignment, and safety hazards. Careful inspection and adjustments are necessary to optimize the vehicle’s performance.

- Verify Ride Height: Measure the ride height of the vehicle at various points (front, rear, and center). Compare these measurements to the specifications provided with the leveling kit. Discrepancies can indicate installation errors, requiring further adjustments. Using a tape measure, ensure that the ride height matches the manufacturer’s specifications. This is crucial for ensuring proper handling and avoiding potential issues with the suspension system.

- Check for Leaks: Inspect all fluid levels (engine oil, transmission fluid, brake fluid, power steering fluid) to ensure they are within the appropriate ranges. Leaks, especially in the suspension components, could lead to premature wear and damage. Look closely for any signs of leakage from the suspension components, such as the shock absorbers, struts, or control arms. A small leak can lead to significant problems over time.

- Inspect Alignment: A properly aligned vehicle ensures optimal handling and tire wear. After installing a leveling kit, a professional alignment is highly recommended. Driving with misaligned wheels can result in increased tire wear, poor handling, and even safety concerns. The impact of improper alignment is more pronounced with modified suspension systems. Proper alignment is vital for both safety and tire longevity.

- Examine Suspension Components: Visually inspect all suspension components for any damage, misalignment, or loose fasteners. Damage to control arms, ball joints, or other components can compromise the integrity of the suspension system. Check for any cracks, bends, or excessive play in the components. Using a torque wrench to ensure the bolts and fasteners are properly tightened according to the manufacturer’s specifications is crucial.

- Assess Steering and Braking: Test the steering and braking systems to ensure smooth operation. Any unusual noises or vibrations during these operations could indicate issues with the leveling kit or other components. Steering and braking issues are potential warning signs of improper installation or underlying damage.

Alignment After Installation

Proper alignment after installing a leveling kit is essential for maintaining vehicle safety and performance. Misalignment can lead to uneven tire wear, poor handling, and potentially dangerous situations. A professional alignment service is highly recommended after any suspension modification.

- Importance of Alignment: Alignment ensures that the tires contact the road at the optimal angle, reducing tire wear and enhancing handling. Misalignment will result in uneven tire wear, potentially dangerous handling, and higher chances of tire failure. This step is crucial for achieving the desired benefits of the leveling kit while ensuring safety on the road.

- Professional Alignment Recommendation: Due to the complexity of suspension modifications, professional alignment services are strongly recommended. This ensures precise adjustments and maximizes the performance and safety of the vehicle. Professional alignment is a crucial step in maximizing the benefits of the leveling kit.

Things to Inspect After Installation

Thorough inspection ensures that the leveling kit is properly installed and that there are no issues with other components.

- Suspension Components: Inspect all suspension components for damage or misalignment.

- Fluid Levels: Check all fluid levels (engine oil, transmission fluid, brake fluid, power steering fluid).

- Steering and Braking: Test the steering and braking systems for smooth operation.

- Ride Height: Measure the ride height at various points on the vehicle and compare to the manufacturer’s specifications.

- Alignment: Have a professional alignment performed to ensure optimal handling and tire wear.

Re-checking Ride Height and Wheel Alignment

Regular re-checking of ride height and wheel alignment is crucial for maintaining the vehicle’s performance and safety. Over time, suspension components may settle or wear, affecting the ride height and alignment.

- Regular Checks: Schedule regular inspections and adjustments as needed to maintain the vehicle’s performance and safety.

- Impact of Neglect: Neglecting regular checks can lead to premature tire wear, handling issues, and potential safety concerns.

Troubleshooting and Common Issues

Installing a leveling kit can be a rewarding experience, but it’s crucial to be prepared for potential problems. Understanding the potential pitfalls and solutions beforehand can prevent frustration and ensure a smooth installation process. Knowing the possible causes and common mistakes during the installation can help you avoid issues and resolve problems efficiently.Careful attention to detail and a thorough understanding of your vehicle’s specific needs are essential for a successful leveling kit installation.

Proper preparation, meticulous execution, and awareness of potential problems are key factors in achieving the desired outcome and maintaining the integrity of your vehicle’s suspension system.

Potential Problems During Installation

Several issues can arise during the leveling kit installation process. These range from seemingly minor inconveniences to more significant problems that require immediate attention. Careful observation and a methodical approach are essential to identify and address these issues promptly.

- Incorrect bolt torque: Improper tightening of bolts can lead to premature failure or damage to components. Over-tightening can strip threads, while under-tightening can lead to loose connections. Using a torque wrench, following the manufacturer’s specifications, and double-checking the tightness is crucial.

- Improper alignment of components: Misalignment of components, such as the shock absorbers or control arms, can cause uneven ride height or other issues. Carefully verifying the alignment of all components and adhering to the manufacturer’s instructions is essential to avoid these problems.

- Component damage: Handling components with care is paramount. Damage to springs, shocks, or other parts can result in uneven ride height, premature wear, or safety concerns. Using proper handling techniques and tools, avoiding unnecessary force, and inspecting parts before installation are critical.

Potential Problems After Installation

Post-installation issues are also possible and can range from minor adjustments to more significant problems requiring professional intervention. Identifying the cause of these issues promptly is essential for effective resolution.

- Uneven ride height: This is a common problem after installation. Uneven ride height can be caused by various factors, including incorrect component installation, improper alignment, or issues with the leveling kit itself. Careful inspection and re-evaluation of the installation process can help diagnose the source of the issue.

- Noise: Unfamiliar noises after installation may indicate issues with the components or the installation itself. Loose bolts, damaged components, or improper alignment can all contribute to noises. Identifying the source of the noise is crucial to implementing the correct solution.

- Excessive vibration: Excessive vibration can be caused by damaged or misaligned components. It is essential to identify the cause of the vibration for effective resolution. Re-evaluating the installation procedure and ensuring all parts are correctly secured is vital.

Common Mistakes During Installation

Avoiding common mistakes during the installation process is critical for achieving a successful outcome. Recognizing these mistakes beforehand can significantly reduce the chances of encountering problems.

- Skipping the pre-installation inspection: Failing to inspect the vehicle’s suspension and components for damage before installation can lead to complications and unexpected problems later. Thoroughly inspecting all parts and confirming their condition before starting is vital.

- Inadequate preparation: Inadequate preparation, such as insufficient space or tools, can cause problems during the installation process. Ensuring you have the right tools, a safe work area, and adequate space for maneuvering are critical.

- Ignoring the manufacturer’s instructions: Deviations from the manufacturer’s instructions can lead to unforeseen issues. Adhering strictly to the manufacturer’s guidelines and instructions is critical for a successful installation.

Safety Precautions

Installing a leveling kit, while enhancing your vehicle’s performance, necessitates meticulous attention to safety. Ignoring crucial safety measures can lead to severe injuries and potential vehicle damage. This section Artikels the critical safety precautions to observe throughout the installation process.Proper safety measures are paramount during leveling kit installations. By adhering to these precautions, you can significantly reduce the risk of accidents and ensure a smooth and safe installation process.

Failure to prioritize safety can result in costly repairs, injuries, and even fatalities.

Essential Safety Equipment

Ensuring you have the right safety gear is critical. The use of appropriate personal protective equipment (PPE) is not optional but a necessity. This includes, but is not limited to, safety glasses, gloves, hearing protection, and sturdy work boots. Protective clothing, such as long sleeves and pants, can also help prevent cuts and abrasions.

Potential Hazards and Mitigation

Several potential hazards can arise during a leveling kit installation. These hazards include, but are not limited to, the risk of cuts, burns, and falls, as well as potential damage to the vehicle’s components. Proper handling of tools and components, as well as the use of appropriate safety measures, can help mitigate these risks.

Safety Precautions for Leveling Kit Installation

A comprehensive list of safety precautions is essential to ensure a secure and injury-free installation.

- Secure the Vehicle: Park the vehicle on a level, stable surface, ideally on a firm, even ground. Using wheel chocks or jack stands is crucial to prevent the vehicle from rolling during the installation process. Always engage the parking brake and use wheel chocks to prevent unexpected movement. This prevents the vehicle from moving unexpectedly, thus preventing potential accidents.

- Proper Lifting Techniques: Use jack stands and/or ramps. Never attempt to lift the vehicle using only the jack. Ensure the jack stands are placed in the correct locations and are sturdy enough to support the weight of the vehicle. Incorrect placement can cause the vehicle to collapse, leading to severe injury.

- Tool Safety: Inspect tools before use to ensure they are in good working order. Use the correct tools for the job. Improper use of tools can cause injury or damage to the vehicle. Always ensure the tools are appropriate for the task, avoiding using inappropriate or damaged tools.

- Clear the Work Area: Clear the area around the vehicle of any obstructions that could pose a tripping hazard or interfere with the installation process. Keep the area free of any unnecessary items or materials to create a safe workspace. This avoids any potential accidents during the installation process.

- Proper Ventilation: Ensure adequate ventilation in the work area, especially if using any chemicals or solvents during the installation process. Improper ventilation can lead to health issues. Maintain proper ventilation to prevent inhalation of harmful fumes or dust.

- Stay Alert: Pay close attention to the installation process and follow the manufacturer’s instructions meticulously. Avoid distractions during the installation process. Always remain vigilant and avoid distractions to maintain focus on the installation process.

- Emergency Procedures: Familiarize yourself with emergency procedures and have a plan in place in case of an accident or injury. Knowing how to respond in an emergency can save lives.

- Proper Use of Equipment: Familiarize yourself with the specifications and proper usage of all tools and equipment used in the installation process. Use equipment in the manner intended and follow safety guidelines.

- Avoid Overexertion: Take breaks as needed to avoid fatigue. Do not attempt to lift or carry heavy objects without assistance. Overexertion can lead to injuries. Break down tasks and work in manageable sections to avoid unnecessary stress on the body.

- Work with a Partner (if possible): For complex tasks, working with a partner can improve safety and efficiency. A second set of eyes can help identify potential hazards and provide support. A partner can provide assistance and support during the installation.

Visual Aids and Illustrations: How To Install A Leveling Kit

Leveling kits, while offering a significant upgrade to a vehicle’s ride height, require a thorough understanding of their components and installation procedures. Visual aids play a crucial role in this process, offering a clear and detailed view of each part, its function, and its importance within the overall system. Illustrations of the installation stages further simplify the procedure, reducing potential errors and ensuring a successful outcome.

Leveling Kit Components

A leveling kit comprises various components that work together to achieve the desired ride height. Understanding the function and importance of each component is essential for a successful installation.

| Component | Image Description | Function | Importance |

|---|---|---|---|

| Coil Springs | A set of springs designed to be stiffer than the original springs, often with varying degrees of stiffness depending on the kit. They may appear as a taller and more substantial spring assembly. | Coil springs increase the suspension’s load capacity and provide support, raising the vehicle’s ride height. They are designed to compress and expand as the vehicle’s weight shifts, ensuring stability and comfort. | Critical for increasing ride height and maintaining suspension function. Incorrect springs can lead to instability or damage. |

| Shock Absorbers | Shock absorbers, possibly modified in length to match the new spring height, often appear as a long, cylindrical unit with mounting points. | Shock absorbers control the suspension’s movement, absorbing impacts and preventing excessive bouncing. They work in conjunction with the springs to maintain the vehicle’s stability. | Essential for controlling suspension movement and preventing harshness or excessive bounce, which can lead to a less comfortable ride and component damage. |

| Spacer(s) | These are typically made of metal, appearing as cylindrical or plate-like components with mounting points. | Spacers are placed between the existing coil springs and the shock absorbers, increasing the distance between them and raising the vehicle’s ride height. They can be different heights and materials. | Critical for achieving the desired ride height. Incorrect spacers can cause misalignment or damage to the suspension. |

| Control Arms | These are components that are attached to the vehicle’s frame and connect to the wheel assembly. They are typically metal brackets with a specific geometry for proper suspension function. | Control arms maintain the proper alignment between the wheels and the suspension system. | Essential for maintaining proper vehicle alignment and handling. Improper alignment can cause uneven tire wear and poor handling. |

| Mounting Hardware | Various bolts, nuts, and brackets used for securing the components to the vehicle’s frame. | Hardware secures the components to the vehicle. | Essential for a secure and stable installation. Damaged or missing hardware can lead to the leveling kit failing. |

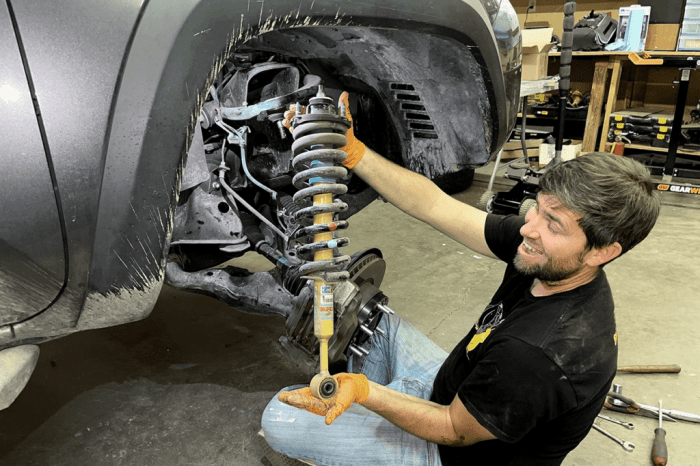

Installation Illustrations

Visualizing the installation process through illustrations can significantly aid in understanding the sequence of steps and potential challenges. Each illustration should depict a specific stage of the installation process with a detailed caption describing the action or part in focus.

Illustration 1: Removing the original coil springs. The illustration should show the original coil springs being removed from the vehicle’s suspension system. The caption should specify the appropriate tools required for removal, and any potential challenges or safety precautions to be observed during this stage.

Illustration 2: Installing the new coil springs. The illustration should depict the process of installing the new coil springs with the correct alignment and tension. The caption should highlight the importance of proper spring placement and potential issues if the springs are not installed correctly.

Illustration 3: Securing the spacers. The illustration should show the spacers being placed between the new springs and the shock absorbers. The caption should describe the correct placement of the spacers, emphasizing the importance of using the correct spacer height for the desired ride height.

Illustration 4: Connecting the new shock absorbers. The illustration should depict the process of attaching the new shock absorbers to the vehicle’s frame, ensuring proper alignment. The caption should emphasize the importance of precise alignment for optimal suspension function and safety.

Illustration 5: Final assembly and tightening. The illustration should showcase the final stages of installation, highlighting the securing of the control arms, and all other components. The caption should detail the importance of using the correct torque specifications for all mounting hardware to ensure a safe and stable installation.

Concluding Remarks

This guide has provided a thorough overview of the process involved in installing a leveling kit, from initial selection to post-installation maintenance. By understanding the steps Artikeld and adhering to safety precautions, vehicle owners can successfully install a leveling kit, enhancing their vehicle’s performance and appearance. Remember, meticulous planning and precise execution are paramount to achieving the desired results and avoiding potential complications.

FAQ Resource

What are the common mistakes during leveling kit installation?

Common mistakes include improper tool usage, overlooking safety precautions, failing to properly prepare the vehicle, and not following the manufacturer’s instructions. Ignoring torque specifications and neglecting wheel alignment adjustments are also frequent errors.

How do I determine if a leveling kit is compatible with my vehicle?

Researching compatibility is crucial. Consult the manufacturer’s website or a reputable online forum for specific vehicle compatibility information. Verify the leveling kit’s specifications and compare them with your vehicle’s technical details, including make, model, and year.

What are the different types of leveling kits available?

Leveling kits come in various forms, such as coil spring kits, air suspension kits, and others. Coil spring kits are the most common type, offering a balance of performance and cost-effectiveness. Air suspension kits provide greater adjustability, while other types cater to specific vehicle needs.

What safety precautions should I take during leveling kit installation?

Safety is paramount. Always wear appropriate safety gear, including gloves, eye protection, and sturdy footwear. Ensure the work area is well-lit and clear of obstructions. Never work under the vehicle without proper jacking support and safety stands.