How to measure an outboard motor shaft length is critical for proper boat and engine compatibility. Accurate measurement ensures optimal propeller function and prevents potential damage to the boat or engine. Factors such as boat type, propeller size, and water conditions significantly impact the selection of the correct shaft length. Understanding these factors and employing the correct measurement techniques are vital for safe and efficient boating operations.

This comprehensive guide provides a detailed overview of the process, from essential tools and measurement methods to troubleshooting common errors. It also explores the relationship between shaft length, propeller compatibility, and various boat types.

Introduction to Outboard Motor Shaft Length Measurement

Yo, peeps! Knowin’ the length of your outboard motor shaft is crucial, like, seriously crucial. It ain’t just some random number; it dictates a whole lot about how your boat runs and how safe you are on the water. From matchin’ the right prop to avoid burnouts to makin’ sure your boat’s stable, this measurement is key.

Get it wrong, and you’re lookin’ at potential problems.This measurement is vital in several situations. For example, when you’re buyin’ a new motor, matchin’ it with your boat’s hull design is essential. You gotta make sure the shaft length fits the boat’s characteristics, or you’ll be lookin’ at a whole lotta problems, like your boat not performin’ at its best.

Also, when you’re doin’ repairs or maintainin’ your outboard, you need to know the exact length to get the right parts and avoid costly mistakes. Plus, if you’re havin’ trouble with your outboard, knowin’ the correct shaft length can pinpoint the problem faster.Inaccurate shaft length measurements can lead to a bunch of issues. For one, you might end up with a motor that’s too long or too short for your boat.

This can cause problems like poor performance, reduced fuel efficiency, and even safety hazards. Also, you might end up with the wrong propeller, which can cause vibration and damage to the motor. In worst-case scenarios, it can even lead to serious accidents.Outboard motor shaft length is the linear distance from the mounting flange to the end of the propeller shaft.

This measurement is crucial for compatibility and performance.

Factors Influencing Shaft Length Selection

Understandin’ what factors influence the perfect shaft length is key. It’s not just a random guess, it’s about gettin’ the right fit for your boat and your desired performance.

| Factor | Explanation |

|---|---|

| Boat Type | Different boat types (e.g., fishing boats, pontoons, speedboats) have different hull designs and depths. This directly impacts the optimal shaft length. |

| Motor Horsepower | Higher horsepower motors often require longer shafts for proper propeller clearance and to handle the added stress. |

| Propeller Size and Pitch | Propeller size and pitch are crucial factors. A larger propeller often needs a longer shaft to clear the hull and avoid interference. |

| Hull Design | The hull’s shape, depth, and transom configuration all play a role in determining the appropriate shaft length. |

| Desired Performance | The desired performance (e.g., speed, fuel efficiency) impacts the selection of the appropriate propeller and, subsequently, the shaft length. |

Tools and Equipment Needed

Yo, peeps, measuring outboard motor shaft length ain’t rocket science, but you gotta have the right tools. This ain’t some DIY project where you just wing it; precision is key, especially if you’re dealing with some serious horsepower. Get your tools right, and you’ll be good to go.

Essential Measuring Tools

To get the exact shaft length, you need some reliable tools. A basic set of tools will do the trick, but having a few extras can help you out in the long run.

- A digital caliper is a must-have. It’s super accurate, and you can easily get one that measures up to 12 inches, or even more. Digital calipers are great for tight spaces, too. They’re super convenient for precise measurements, and you can read the measurement right on the screen. This is way better than using a ruler that can be hard to read accurately.

- A steel measuring tape is also crucial. It’s handy for longer measurements, and the steel ensures it stays accurate even under pressure. You need one that’s durable, and can measure up to 25-30 inches. This is good for a larger area.

- A set of precision-grade feeler gauges is another important tool. These gauges are designed for measuring small gaps, which can be super useful when checking the shaft’s clearance. This is important for making sure the shaft fits properly, and it also helps you prevent any potential issues.

Accuracy Levels and Tool Maintenance

Getting the right accuracy level is key to getting the job done right. Different tools have different levels of precision, and it’s important to choose the right tool for the job. Proper tool maintenance is equally important, so you can keep them working like new.

| Tool | Function | Accuracy Level | Maintenance |

|---|---|---|---|

| Digital Caliper | Precisely measures internal and external dimensions | 0.01 mm or better | Clean regularly, check for damage, calibrate periodically |

| Steel Measuring Tape | Measures length | +/- 1mm | Keep away from moisture, store properly |

| Feeler Gauges | Measures small gaps and clearances | 0.01mm – 0.05mm | Clean the gauges, store them in a safe place |

Proper tool maintenance ensures longevity and accuracy. Keep your tools clean and well-maintained, and they’ll serve you well for years to come.

Specialized Tools for Different Outboard Motor Types

Some outboard motors might require specialized tools. For example, some motors have unique shaft designs, and you might need specific tools to measure those.

- For older, larger outboard motors, you might need a special shaft measuring gauge. These tools are specifically designed to accommodate the unique dimensions of older models.

- If you’re dealing with an outboard motor with a complex shaft design, a specialized shaft measuring tool might be necessary. These tools provide greater precision and can handle unique shaft geometries.

Methods for Measuring Shaft Length: How To Measure An Outboard Motor Shaft Length

Yo, so you wanna know how to measure that outboard motor shaft length, right? It’s crucial for getting the right props and making sure your boat’s running smooth. This ain’t rocket science, but you gotta know the moves. Different methods for different motors, so keep your eyes peeled.Measuring the shaft length accurately is key for matching the correct propeller to your outboard motor.

This ensures optimal performance and prevents damage to your engine or boat. Different types of outboards might need different techniques, so let’s dive into the methods.

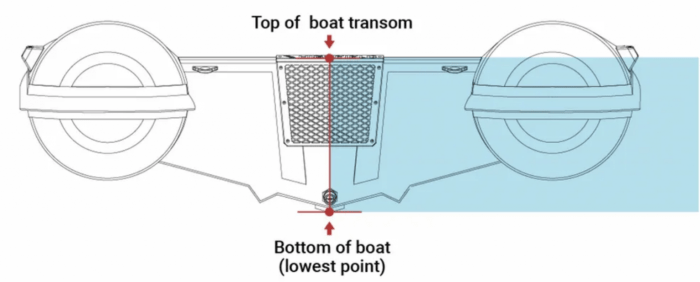

Standard Method for Measuring Outboard Motor Shaft Length

This is the basic method for most outboard motors. It’s straightforward and gives you a precise measurement. Follow these steps:

- Gather your tools: You’ll need a measuring tape, preferably one with a locking mechanism, a sturdy surface to rest the motor on, and safety gear like gloves and eye protection. This stuff’s important, especially if you’re working on a boat.

- Position the motor: Carefully place the outboard motor on a stable surface. Make sure it’s level and won’t move during the measurement process. This is vital for accurate readings.

- Locate the shaft: Identify the outboard motor’s shaft. It’s usually a metal rod extending from the lower unit. The location of the shaft is key.

- Measure the shaft: Use the measuring tape to measure the length of the shaft from the lower unit’s mounting flange to the end of the shaft itself. A precise measurement is critical for the best results.

- Record the measurement: Note down the measurement precisely. Write it down somewhere safe, or use a digital device for easier recording.

Alternative Methods for Different Outboard Motor Types

Some older or specialized outboard motors might have unique shaft configurations. These methods may require additional tools or steps.

- For motors with unusual shaft configurations, you might need to use a calibrated measuring tool like a vernier caliper or a micrometer. These tools provide more precise measurements than a tape measure.

- If the shaft is angled or has unusual bends, you might need to use a series of measurements. Taking measurements at multiple points and averaging them is crucial for accuracy.

- Always consult your outboard motor’s manual for specific instructions on how to measure the shaft length. Your manual should have detailed instructions tailored to your particular motor model.

Comparison of Measurement Methods

| Method | Advantages | Disadvantages |

|---|---|---|

| Standard Tape Measure | Simple, readily available, relatively inexpensive. | Less precise than other methods, potential for errors due to bending or misalignment. |

| Vernier Caliper/Micrometer | Highly precise, can handle complex shaft geometries. | More complex to use, requires specialized tools. |

| Multiple Point Measurements | Accounts for shaft bends or angles, enhances accuracy. | More time-consuming, requires careful planning. |

Safety Precautions During Measurement

Safety is paramount during any mechanical work. Remember these precautions:

- Wear appropriate safety gear: Gloves to protect your hands and safety glasses to shield your eyes from any debris or flying objects.

- Ensure a stable work area: The outboard motor should be placed on a stable surface to prevent accidents during the measurement process. A wobbly surface could lead to a fall or injury.

- Be cautious when using tools: Always handle tools with care to avoid injuries. Use the right tools for the job to prevent damage or accidents.

- Inspect the motor carefully: Check for any loose parts or potential hazards before beginning the measurement process. A quick visual inspection can save a lot of trouble.

Factors Affecting Shaft Length

Yo, fam, so you wanna know what makes a shaft the right length for your boat? It’s not just about eyeballing it, there’s a science to it, especially if you don’t want your motor to be a total pain in the neck. Different factors play a huge role, and understanding them is key to getting the perfect fit.Shaft length isn’t some random number pulled out of thin air.

It’s all about matching the motor to the boat, the prop, the water, and even the engine’s power. This stuff is crucial for a smooth ride and optimal performance.

Boat Type Influence on Shaft Length

Different boat types have different needs when it comes to shaft length. A speedboat, for example, might need a shorter shaft than a fishing boat. The hull shape, the size of the boat, and its intended use all influence the ideal shaft length. A bigger, heavier boat will require a longer shaft to properly support the motor’s weight and distribute the load.

This helps prevent excessive stress on the boat’s structure and ensures optimal performance. For example, a pontoon boat needs a longer shaft to accommodate its wider beam and lower center of gravity.

Propeller Size Impact on Shaft Length

The size of the propeller directly impacts shaft length. A bigger propeller usually needs a longer shaft to ensure proper engagement and avoid unnecessary strain on the motor. A smaller propeller might work with a shorter shaft, but it might not be optimal for the boat’s speed and performance. Think of it like a gear ratio: a larger propeller needs more space to work effectively.

Water Depth and Boat Draft Influence on Shaft Length

Water depth and boat draft are also vital considerations. If you’re planning to operate in shallow waters, you need a shaft length that allows the propeller to clear the bottom. A longer shaft will increase the distance between the propeller and the water bottom. Too short, and you’re gonna run into trouble, especially in tight spaces. Boat draft is the depth of the boat’s hull below the waterline.

A deeper draft often necessitates a longer shaft to ensure the propeller submerges properly. For example, a boat with a shallow draft might need a shorter shaft to avoid hitting the bottom in shallow water.

Shaft Length Recommendations for Various Boat Types and Engine Sizes

| Boat Type | Engine Size (HP) | Recommended Shaft Length (inches) |

|---|---|---|

| Small Runabout | 25-50 | 13-18 |

| Medium-sized Fishing Boat | 50-75 | 18-22 |

| Large Fishing Boat | 75-100 | 22-26 |

| Pontoon Boat | 50-150 | 20-30 |

This table provides a general guideline. Always consult the manufacturer’s specifications for precise recommendations. The actual shaft length required can vary depending on the specific boat and engine models.

Shaft Length and Engine Horsepower Relationship

Engine horsepower plays a crucial role in determining the appropriate shaft length. Higher horsepower engines often require longer shafts to manage the increased power output. A more powerful motor needs more space and support to avoid causing excessive stress and strain on the shaft itself. A high-powered engine needs a longer shaft to handle the torque and rotational forces, preventing premature wear and tear.

For instance, a 150-horsepower engine will likely need a longer shaft than a 50-horsepower engine.

Troubleshooting and Common Mistakes

Yo, so you tryna measure your outboard motor shaft length like a pro? It’s not rocket science, but mistakes happen, especially when you’re rushing or not paying attention. Knowing how to spot and fix those errors is key to getting the right measurement every time. This ain’t no guessing game, fam.This section breaks down common blunders in shaft length measurement, showing you how to avoid them and what to do if things go sideways.

We’ll cover potential issues and give you practical examples so you can troubleshoot like a boss. Get ready to level up your outboard motor game!

Common Measurement Errors

Understanding common errors is crucial to avoiding inaccurate measurements. These mistakes can stem from improper tool usage, environmental factors, or even a lack of attention to detail. Knowing the potential pitfalls beforehand will save you headaches and ensure a precise measurement.

- Incorrect Ruler Placement: Using a ruler that’s not perfectly aligned with the shaft can throw off the measurement. This can happen if the ruler isn’t straight or if you don’t hold it firmly against the shaft. You gotta make sure the ruler is parallel to the shaft and the zero mark is precisely on the beginning of the shaft.

If the ruler is crooked, your measurement will be off. You could even end up with a shaft that’s too short or too long. This is a rookie mistake, but easy to fix.

- Parallax Error: This happens when you’re not looking directly at the ruler’s markings when taking the measurement. Your eye position relative to the ruler affects the reading. Make sure your eye is directly above the measurement point on the shaft. A little shift in your head can lead to a considerable difference in the reading.

- Insufficient Lighting: Poor lighting can make it hard to see the markings clearly. This can lead to misreading the scale, especially when working in dim conditions. Good lighting is key. A bright, clear area will make the measurements easier to read. Think about using a flashlight or a headlamp if necessary.

Rectifying Measurement Errors

Fixing measurement mistakes is easier than you think. Knowing how to identify and correct these errors can save you time and frustration. Here are some ways to rectify those measurement snafus:

- Double-Checking Measurements: Taking the measurement twice using the same technique can confirm the accuracy of the first reading. If both readings are similar, you’ve got a good measurement. If they differ, you should recheck your procedure.

- Proper Ruler Alignment: Using a straight edge to ensure the ruler is perpendicular to the shaft can correct misalignment issues. If the ruler is not aligned, the measurement will be off. Make sure the ruler is firmly pressed against the shaft. This ensures a precise reading.

- Improved Lighting: Use a bright light source to eliminate shadows and improve visibility. This will help you read the ruler’s markings with accuracy. A good light source can dramatically improve the measurement process.

Potential Issues Related to Inaccurate Measurements

Inaccurate shaft length measurements can lead to various problems. Mismatched shaft length and motor can cause issues with performance, stability, and even engine damage. You don’t want a motor that’s too long or too short.

- Improper Installation: A shaft that’s too long or too short can make installing the motor difficult or even impossible. This can cause stress on the motor mounts and potentially lead to damage over time.

- Performance Issues: An incorrect shaft length can affect the boat’s performance. The motor might not run as smoothly, or it could struggle to reach its maximum speed. In extreme cases, this could lead to poor fuel economy.

- Safety Concerns: If the shaft is improperly fitted, it might not align with the hull or transom properly. This could compromise the stability and safety of the boat, especially at high speeds. A correctly fitted shaft is important for a safe boating experience.

Troubleshooting Scenarios, How to measure an outboard motor shaft length

Let’s look at some real-world examples:

- Scenario 1: The measured shaft length is significantly different from the manufacturer’s specifications. Recheck your measurements, ensuring proper alignment and lighting. Double-check your ruler for any imperfections. Compare the results with other reliable sources to identify any potential errors. If the issue persists, consult the motor’s manual or a professional.

- Scenario 2: The outboard motor won’t install properly. Ensure the shaft length aligns with the transom and hull. Check for any obstructions or damage to the transom. Double-check the motor’s specifications and the hull’s requirements. If the issue persists, consult a mechanic.

Troubleshooting Table

| Potential Problem | Solution |

|---|---|

| Incorrect ruler placement | Ensure the ruler is properly aligned and perpendicular to the shaft. Use a straight edge if necessary. |

| Parallax error | Look directly at the ruler’s markings to avoid misinterpreting the reading. |

| Insufficient lighting | Use a bright light source to eliminate shadows and improve visibility. |

| Motor won’t install | Verify the shaft length matches the specifications. Ensure proper alignment with the transom and hull. |

Shaft Length and Compatibility

Yo, so you wanna make sure your outboard motor and propeller are a perfect match, right? This ain’t no game, fam. Wrong shaft length can lead to some serious issues, from the motor vibrating like crazy to the propeller not spinning properly. We’re breaking down how to get it right, so you can cruise smooth as silk.

Importance of Correct Shaft Length

Proper shaft length is crucial for optimal propeller operation. A shaft that’s too long or too short can throw off the whole system’s balance, causing vibrations, reduced efficiency, and even potential damage to the motor or the boat. Think of it like a finely tuned machine; every part needs to be in the right spot for peak performance.

Consequences of Incorrect Shaft Length

Using the wrong shaft length can lead to a whole host of problems. A too-long shaft can cause the propeller to rub against the hull, which can lead to overheating and damage. A too-short shaft can cause the propeller to not fully engage with the water, resulting in poor performance and reduced speed. Imagine trying to drive a car with a mismatched transmission—it’s gonna be a rough ride.

Ensuring Outboard-Propeller Compatibility

To ensure compatibility, you need to match the shaft length specified by the outboard motor manufacturer with the propeller’s design. This is usually printed on the motor’s specs sheet or the propeller itself. Different boat types and sizes will also have specific shaft length requirements. This info is critical to avoid issues.

Verifying Compatibility

To double-check compatibility, carefully compare the shaft length specified on the outboard motor’s documentation with the shaft length of the propeller you’re considering. Use a ruler or a measuring tape to get precise measurements. If the numbers don’t match, you might need to look for a propeller with a compatible shaft length. You don’t want to risk ruining your whole setup.

Selecting the Correct Propeller

Choosing the right propeller for your specific shaft length is key. Consult the motor’s documentation or a reliable online resource to find compatible propeller models. Different propellers are designed for various speeds and loads, and the shaft length directly impacts the propeller’s performance. You can find charts or tables that provide guidance on propeller selection based on shaft length and desired performance.

Basically, you gotta pick the right tool for the job. This will help your boat cruise smoothly and efficiently.

Visual Aids and Illustrations

Yo, peeps! Figuring out outboard motor shaft length ain’t rocket science, but visuals make it way easier to grasp. These diagrams and illustrations are your ultimate cheat sheet for nailing the measurement process. Visuals are key to avoiding those common measurement mix-ups.

Creating Measurement Diagrams

Visual aids are crucial for understanding the measurement process. Clear diagrams help visualize the steps involved in measuring an outboard motor shaft length, making the whole process less confusing and more straightforward. These diagrams should be simple, yet detailed enough to show the critical aspects of the measurement.

- Diagram of the Measurement Process: A step-by-step sequence, showing the measuring tape, ruler, or other tools, placed correctly at the necessary points on the shaft. Highlight the starting and ending points of the measurement. This will help avoid mistakes. Include a clear indication of the units used (e.g., inches, centimeters). Imagine a simple flowchart, but visual, with each step shown as a box or shape.

- Diagram of Different Outboard Motor Types: Show different outboard motor models with varying shaft lengths. Illustrate how the shaft length relates to the overall motor design. This is crucial, because not all motors are built the same, and a bigger motor doesn’t always mean a longer shaft. Use different colours to differentiate the various parts of the motor and its shaft.

- Diagram Highlighting Shaft Length, Propeller, and Hull: Illustrate how the shaft length impacts the propeller’s immersion and the boat’s hull. A simple diagram, showing the shaft protruding from the motor, connecting to the propeller, and ending in the water. Include an arrow to highlight the length being measured. This will help you see how the length impacts the water and boat’s interaction.

Common Measurement Errors

Visualizing common errors is a major part of learning. A visual representation of these errors can highlight what to avoid during the measurement process.

- Incorrect Measurement Position: A diagram showcasing how to position the measuring tool. The diagram should highlight the correct position and include an incorrect example. Show the measuring tape or ruler in the wrong place, and then highlight the correct position. This is a major error, and seeing it visually will help you avoid it.

- Incorrect Unit Measurement: A diagram showing the correct unit (inches, cm, etc.) with examples of wrong units to avoid confusion. Show an example of using the wrong unit (e.g., measuring in feet when you should be measuring in inches). This is vital to avoid problems with compatibility.

Flowchart for the Entire Process

A flowchart is a fantastic way to visualize the entire process of measuring an outboard motor shaft length. It makes the process easy to follow.

- Step-by-Step Visual Flowchart: A visual flowchart illustrating the steps from selecting the correct tools to recording the measurement, with each step shown in a clear, distinct box. Use arrows to show the sequence. Include a start and end point to the flowchart. This helps visualize the process and shows how each step relates to the next. This visual aid is essential for understanding the overall procedure.

Specific Outboard Motor Models

Yo, fam! Figuring out the right shaft length for your outboard motor is crucial. It’s like picking the perfect pair of shoes—wrong size, and you’re in for a rough ride. Knowing the specific model and its specs is key to getting it right.

Measurement Process for a Specific Outboard Motor Model

To nail the shaft length for a particular outboard motor model, you gotta follow a few steps. First, grab the motor’s model number—it’s usually printed somewhere on the motor itself or in the manual. Then, you need to locate the manufacturer’s specifications. This usually involves checking their website or digging through the manual. These docs will have the exact shaft length measurements.

Shaft Length Specifications for Various Outboard Motor Models

This table provides a quick peek at some common outboard motor models and their corresponding shaft lengths. It’s not an exhaustive list, but it gives you a general idea.

| Motor Model | Shaft Length (inches) |

|---|---|

| Yamaha F150 | 18 |

| Honda BF9.9 | 14 |

| Mercury 40 | 16 |

| Suzuki DF140 | 20 |

| Tohatsu M15 | 15 |

Important Note: Always cross-reference these figures with the manufacturer’s documentation for your specific model. The table is a general guideline only, and details may vary.

Importance of Consulting Manufacturer’s Specifications

Consulting the manufacturer’s specs is essential for avoiding compatibility issues and ensuring a smooth operation. The specs usually provide precise details on shaft length, and these vary based on the specific motor’s features and design. This is not just some extra step—it’s about preventing potential problems down the line. Ignoring these details can lead to mismatches, resulting in a less-than-perfect fit.

Finding the Correct Shaft Length for Different Models

Locating the correct shaft length involves a few steps. First, identify the outboard motor’s model number. Then, you should refer to the manufacturer’s specifications. This can be done by checking the motor’s documentation, contacting customer service, or visiting the manufacturer’s website. The correct length is vital for proper performance and safety.

Comparison of Shaft Lengths for Similar Models with Different Horsepower Ratings

Different horsepower ratings of similar models may have different shaft lengths. A higher horsepower rating usually correlates with a longer shaft length. This is due to the increased load and demands on the motor’s design. For instance, a 150 horsepower motor might have a longer shaft than a 90 horsepower version of the same model. The longer shaft is engineered to handle the greater load.

Last Point

In conclusion, accurately measuring an outboard motor shaft length is paramount for ensuring optimal performance, safety, and longevity. This guide has provided a structured approach, encompassing the necessary tools, methods, and considerations. By meticulously following the steps Artikeld, boat owners can confidently select the appropriate shaft length for their specific needs, thereby maximizing the performance and lifespan of their outboard motor and boat.

Questions and Answers

What is the typical error margin for shaft length measurements?

Acceptable error margins for shaft length measurements vary depending on the precision of the tools used. Generally, errors exceeding 1/16th of an inch are undesirable and should be avoided. For critical applications, a more stringent tolerance may be necessary.

How do I select the right propeller for a specific shaft length?

Propeller selection is guided by the manufacturer’s specifications for the particular outboard motor and shaft length. Online resources and marine supply stores can provide further guidance on propeller compatibility.

What are the potential consequences of using an incorrect shaft length?

Using an incorrect shaft length can result in reduced performance, vibration, noise, and potential damage to the outboard motor, propeller, or boat. This can lead to costly repairs and safety concerns.