How to measure shaft length outboard motor accurately is crucial for boat owners. A precise measurement ensures compatibility with your boat and propeller, preventing costly replacements and potential damage. Understanding the importance of this seemingly simple task can save you headaches and ensure a smooth sailing experience. From selecting the right tools to troubleshooting common measurement issues, this guide walks you through every step of the process.

This comprehensive guide covers everything from understanding the significance of accurate shaft length measurement to detailed explanations of various methods and potential pitfalls. We’ll equip you with the knowledge and tools to confidently measure your outboard motor shaft, ensuring optimal performance and longevity.

Introduction to Measuring Outboard Motor Shaft Length

Getting the right shaft length for your outboard motor is like finding the perfect pair of jeans – it’s all about fit. A precise measurement isn’t just about aesthetics; it’s crucial for optimal performance and longevity of your precious boat-powered machine. Mismatched shaft length can lead to a whole host of problems, from reduced efficiency to potentially serious damage.

So, let’s dive into why this seemingly simple measurement is so important.Precise measurement of outboard motor shaft length is vital for proper boat compatibility and engine performance. The shaft’s length directly impacts how well the motor transmits power to the water, influencing the boat’s speed, fuel efficiency, and overall handling. Think of it as the engine’s connection to the water; a mismatched length is like trying to drive a car with the wrong size transmission.

Importance of Accurate Shaft Length Measurement

Incorrect shaft length can lead to a cascade of problems. Poor alignment between the motor and the boat’s drive system can result in reduced power output, increased vibration, and premature wear and tear on crucial components. This isn’t just about a little bit of extra noise; it can be the difference between a smooth, enjoyable boating experience and one filled with frustrating issues.

Scenarios Where Incorrect Shaft Length Can Cause Issues

Using an incorrectly sized shaft can lead to a variety of problems. A shaft that’s too short might not engage with the lower unit properly, causing the motor to struggle and potentially overheat. Conversely, a shaft that’s too long might result in the propeller being submerged in the water less efficiently, affecting the boat’s speed and fuel economy. These problems aren’t just minor annoyances; they can lead to costly repairs and significantly diminish your boating enjoyment.

Potential Consequences of Using an Incorrectly Sized Shaft

The consequences of using an incorrect shaft length are significant and can be costly. A poorly matched shaft can cause a motor to vibrate violently, leading to potential damage to the motor housing and other critical components. This can lead to costly repairs and even render the motor unusable. Imagine trying to use a pair of scissors to cut through a brick wall – that’s essentially what you’re doing with an incompatible shaft.

Comparison of Outboard Motor Types and Typical Shaft Length Ranges

| Outboard Motor Type | Typical Shaft Length Range (inches) |

|---|---|

| Small, Recreational (4-15 hp) | 10-24 |

| Mid-Range (15-40 hp) | 12-30 |

| Large, Performance (40 hp+) | 24-48 |

This table provides a general guideline for shaft length ranges, but the specific length will depend on the exact model and the boat’s design. Always consult the manufacturer’s specifications for your particular outboard motor and boat combination. Don’t be a DIY disaster!

Tools and Equipment Needed for Measurement

Alright, intrepid outboard motor enthusiasts! Ready to delve into the fascinating world of precise shaft length determination? We’re not just measuring; we’re embarking on a quest for the perfect fit, a journey that demands the right tools. Without the right tools, you’re just winging it, and we all know how well that works out!Armed with the proper instruments, you’ll be able to confidently tackle any shaft length measurement, from the humble little 4-horsepower to the mighty 150-plus behemoths.

This section will equip you with the necessary tools and knowledge to achieve accurate measurements, ensuring your outboard motor performs at its peak.

Essential Measuring Tools

Accurate measurement is paramount. Choosing the right tools will determine the accuracy of your final shaft length measurement. These tools, like trusty sidekicks, will help you navigate this measurement mission.

- A high-quality digital caliper is your best friend. Its precise readings, often accurate to 0.01 inches or millimeters, are crucial for ensuring your outboard motor is a perfect fit. Look for models with a sturdy construction and clear, easy-to-read displays.

- A reliable steel tape measure, preferably one with metric and imperial measurements, provides quick and straightforward length measurements. Its versatility makes it a valuable addition to your toolkit. Choose a tape measure with a robust, non-stretching material for reliable measurements. A retractable tape measure is even more convenient, allowing for storage and easy deployment.

- A sturdy, non-flexible measuring rod or ruler, often with a graduated scale, is your next reliable choice. It is suitable for measurements that are long enough and can provide an accurate measurement for the outboard shaft. For greater accuracy, look for a measuring rod made from high-quality material that doesn’t bend or distort under pressure.

Comparing Different Measuring Tools

Different tools cater to different needs. A digital caliper excels at precise readings, ideal for small increments. Tape measures, on the other hand, are better for larger measurements. Measuring rods offer a straightforward method for certain lengths. Choose the tool best suited to the job at hand, ensuring the desired accuracy.

- Digital calipers offer the most precision, but they can be more expensive than tape measures. They are ideal for critical measurements, where fractions of a millimeter matter.

- Tape measures provide versatility, covering a wide range of lengths, but they might not always be as precise as digital calipers.

- Measuring rods are perfect for simple, straightforward measurements over a considerable distance. They offer a simple yet reliable method.

Calibration and Accuracy

Calibration is crucial for ensuring the accuracy of your measuring tools. Just like tuning a musical instrument, you need to calibrate your measuring tools to ensure their reliability. Uncalibrated tools are like a car without proper alignment – they lead to errors in your measurements.

Calibration ensures your measurements are accurate, and errors are minimized.

- Regularly calibrate your measuring tools to maintain their accuracy. This is like performing routine maintenance on your car; it prevents significant problems down the road.

- Use calibrated tools to ensure consistent measurements and avoid costly mistakes. Always double-check the calibration dates to ensure accuracy.

Tool Selection Table

This table summarizes the recommended tools for various shaft length measurement scenarios.

| Tool | Description | Appropriate Use |

|---|---|---|

| Digital Caliper | High precision, digital readout | Precise measurements of small shaft sections, fine adjustments |

| Steel Tape Measure | Versatile, long-range measurement | Measuring the overall length of the shaft |

| Measuring Rod | Simple, straightforward, long-range | Measuring shaft length in situations where precision is less critical |

Methods for Measuring Outboard Motor Shaft Length

Ah, the glorious quest for precise outboard motor shaft dimensions! This isn’t rocket science, but it’s certainly more precise than guessing how many beers you can chug before your boat capsizes. Understanding the various methods, from the simple to the slightly more sophisticated, is key to getting the right fit for your watercraft. Let’s dive in!

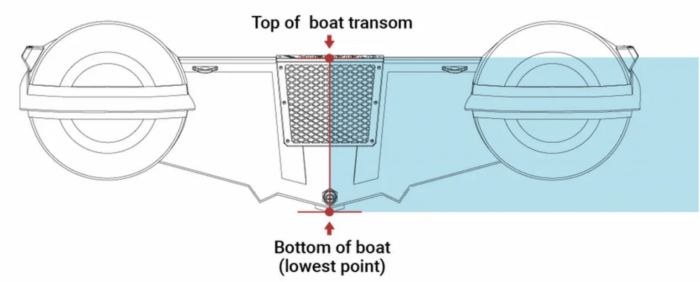

Standard Methods for Shaft Length Measurement

Knowing how to accurately measure your outboard motor shaft length is crucial for proper installation and compatibility. Different methods offer varying degrees of precision and ease of use. A common thread among all methods is the need for a steady hand and a keen eye, and, of course, the right tools.

Using a Ruler

A simple ruler, often overlooked in the world of high-tech measurements, is surprisingly effective for basic shaft length estimations. Position the ruler alongside the shaft, ensuring it’s perpendicular to the shaft’s axis. Carefully align the ruler’s zero mark with one end of the shaft. The mark on the ruler where the other end of the shaft aligns is the measurement.

A well-lit area and a stable surface are your best friends here. If you’re measuring a tricky curve, you might need to use a straight edge to ensure accuracy. This method is best for quick checks and ballpark figures.

Employing a Caliper

For a more refined approach, consider using a caliper. A caliper, with its precise jaws, provides a more accurate reading compared to a ruler. First, carefully position the caliper’s jaws against the shaft ends, ensuring the caliper is perpendicular to the shaft’s axis. Then, read the measurement displayed on the caliper’s scale. This method is ideal for determining precise dimensions and can handle slightly curved or irregular shaft shapes.

Comparison of Measurement Methods

| Method | Accuracy | Precision | Ease of Use | Cost ||—————-|————|————|————|————|| Ruler | Low | Low | High | Low || Caliper | High | High | Moderate | Moderate |

Detailed Explanation of Ruler and Caliper Use

Ruler

A simple ruler, often overlooked, is surprisingly effective for basic shaft length estimations.

Position the ruler alongside the shaft, ensuring it’s perpendicular to the shaft’s axis. Carefully align the ruler’s zero mark with one end of the shaft. The mark on the ruler where the other end of the shaft aligns is the measurement.

Caliper

A caliper, with its precise jaws, provides a more accurate reading compared to a ruler.

First, carefully position the caliper’s jaws against the shaft ends, ensuring the caliper is perpendicular to the shaft’s axis. Then, read the measurement displayed on the caliper’s scale. Ensure that the caliper is correctly calibrated for accurate measurements. If you’re dealing with a curved or irregular shaft, a digital caliper might be more suitable for precise readings.

Factors Affecting Shaft Length Measurement Accuracy

Measuring your outboard motor shaft’s length is crucial for proper boat operation and motor maintenance. But just like a finely tuned engine, precise measurement depends on more than just the tools you use. Environmental conditions and human error can throw a wrench in your best-laid plans, leading to inaccurate readings. Let’s dive into the sneaky factors that can affect your measurements, and how to avoid the “shaft-length-measurement-mishaps.”

Environmental Factors Affecting Accuracy, How to measure shaft length outboard motor

Environmental conditions, like a fickle weather pattern, can significantly impact the accuracy of your shaft length measurement. Temperature fluctuations, humidity levels, and even air pressure can cause the metal shaft to expand or contract, skewing your results. Think of it like trying to measure a hot dog in a sauna – it’s going to be a little longer than you expect!

Temperature Fluctuations

Temperature changes can cause the shaft material to expand or contract, a phenomenon known as thermal expansion. This means that a shaft measured on a hot day will appear slightly longer than the same shaft measured on a cold day. A 10-degree Celsius change can lead to a noticeable, though not drastic, difference in the measurement. This is why it’s important to maintain a consistent temperature throughout the measurement process.

For example, if you measure in a shaded area on a hot day, the shaft will be slightly longer than if you measured it in the direct sun.

Humidity and Other Environmental Conditions

Humidity, and other environmental conditions, such as air pressure, can also impact the accuracy of the measurement. High humidity can lead to moisture accumulation on the shaft’s surface, affecting the accuracy of your measurement. Similarly, drastic changes in air pressure can cause the shaft to expand or contract in unexpected ways. Think of it like a balloon in different atmospheric pressures; it will inflate or deflate accordingly.

Mitigating Environmental Factors

To minimize the impact of environmental factors, follow these guidelines:

- Choose the right time for measurement: Measure the shaft during stable weather conditions, preferably on a day with moderate temperature and low humidity. Avoid extremely hot or cold days and days with fluctuating humidity levels.

- Maintain a stable environment: If possible, conduct measurements in a controlled environment, such as a well-ventilated, climate-controlled area. This will help minimize the effects of temperature and humidity fluctuations.

- Allow the shaft to acclimatize: If you’re measuring a shaft that has been exposed to different temperatures, allow it to reach room temperature before taking the measurement. This ensures the shaft is at a consistent temperature as the measuring instrument.

Human Error Factors

Human error is another crucial factor that can influence the accuracy of your shaft length measurement. This includes misreading the measuring device, incorrect positioning of the measuring tool, and other errors in technique. Human error can be more impactful than environmental factors in certain cases. Imagine trying to measure a tiny piece of spaghetti with a ruler – you might accidentally misalign the ruler.

Minimizing Measurement Errors

To minimize human error, adhere to these practical tips:

- Use a reliable measuring device: Invest in a high-quality measuring tool that provides precise measurements. A digital caliper or a micrometer are excellent choices for accurate measurements.

- Ensure proper positioning: Carefully position the measuring tool against the shaft, ensuring that the measurement is taken at the appropriate points, perpendicular to the shaft’s surface.

- Double-check measurements: Double-check your readings to verify accuracy. If possible, have another person verify the measurement to reduce the chance of human error.

- Maintain proper technique: Take your time and follow the correct procedures for measuring the shaft length. Thoroughness is key to minimizing human error.

Troubleshooting Common Measurement Issues: How To Measure Shaft Length Outboard Motor

Ever had your outboard motor shaft measurement go haywire? Don’t fret, captain! We’ll navigate the tricky waters of potential pitfalls and get your measurements back on track. From errant rulers to eccentric engines, we’ll tackle the common problems that can throw off your shaft-length calculations.This section delves into the common snags encountered during outboard motor shaft length measurements, offering clear explanations of why inaccuracies occur and, crucially, how to resolve them.

Precise measurements are paramount for proper boat maintenance and performance.

Common Measurement Errors and Their Causes

Understanding why your measurements are off is the first step towards fixing them. Just like a grumpy seagull, sometimes the problem isn’t the measurement itself, but the tools, environment, or even the engine’s idiosyncrasies.

- Inaccurate Ruler/Tape Measure: A bent ruler or a tape measure that stretches or contracts can lead to erroneous readings. Imagine trying to measure your boat’s length with a rubber band – it’s bound to be inaccurate!

- Improper Alignment: A misaligned ruler or tape measure, or a tilted shaft, can easily introduce errors. Picture trying to measure a crooked fence post – it won’t be accurate!

- Environmental Factors: Temperature fluctuations can affect the accuracy of measurements, especially with metal objects. Imagine trying to measure a hot metal pipe – it will expand, making the measurement inaccurate.

- Shaft Wear or Damage: A worn or damaged shaft won’t give you an accurate measurement. Think of trying to measure the length of a broken pencil – the result is flawed!

- Parallax Error: Looking at the ruler from an angle can introduce a parallax error, creating a false reading. It’s like trying to judge the distance of a ship from the shore by squinting – it’s not precise!

Resolving Measurement Inaccuracies

Once you identify the source of the error, you can apply the appropriate solution. It’s like diagnosing a sick engine – you need the right tools and knowledge to fix it.

- Accurate Ruler/Tape Measure: Ensure your ruler or tape measure is straight and free of kinks or bends. Use a sturdy, calibrated ruler for precise readings. This is like using a high-quality measuring tape to ensure accurate construction.

- Proper Alignment: Place the ruler or tape measure perpendicular to the shaft. Use a level to guarantee accurate alignment, especially for angled shafts. This is like using a carpenter’s level to ensure a perfect straight line.

- Controlling Environmental Factors: Measure the shaft in a stable environment, free from extreme temperatures. Try to take your measurements in a temperature-controlled space, if possible. This is like keeping a lab environment stable to ensure precise scientific measurements.

- Inspect Shaft Condition: Visually inspect the shaft for any signs of wear or damage. If necessary, replace the shaft to ensure accurate measurement. This is like checking your tires for wear and tear before driving – it ensures a smooth ride.

- Avoiding Parallax Error: Maintain a consistent eye-level position while taking the measurement. Position yourself directly over the shaft and ruler to avoid any parallax error. This is like taking a picture – you need to be in the right position to capture a clear image.

Troubleshooting Table

| Problem | Cause | Solution |

|---|---|---|

| Inaccurate reading | Bent or stretched tape measure | Use a new, calibrated ruler or tape measure. |

| Measurement discrepancy | Misaligned ruler/tape measure | Ensure the ruler/tape measure is perpendicular to the shaft. Use a level. |

| Varying results | Environmental factors (temperature) | Measure in a stable environment. |

| Incorrect shaft length | Shaft damage/wear | Inspect the shaft for damage. If damaged, replace. |

| Inaccurate measurement | Parallax error | Position yourself directly over the shaft and ruler. |

Shaft Length Chart and Specifications

Ever feel like your outboard motor’s shaft is a secret code, only decipherable by marine engineers? Fear not, intrepid angler! This section unlocks the mysteries of shaft length, revealing the vital specifications hidden within the depths of your outboard motor’s data sheet. Understanding these measurements is crucial for proper boat compatibility and overall performance.This section delves into the fascinating world of shaft length charts, providing a comprehensive guide to deciphering the specs for various outboard motor models.

We’ll explore how these charts are organized, what information they contain, and how to use this knowledge to ensure your boat and engine are a perfect match. Prepare to become a shaft-length savvy superstar!

Outboard Motor Shaft Length Specifications

Knowing your outboard motor’s shaft length is like having a secret weapon. It ensures proper fitment with your boat, impacting everything from fuel efficiency to overall performance. A correctly matched shaft length avoids potential problems, including premature wear and tear, and potential engine damage.

| Outboard Motor Model | Manufacturer | Shaft Length (inches) | Image Description |

|---|---|---|---|

| Yamaha F150 | Yamaha | 22 | A sleek, silver Yamaha F150 outboard motor is depicted, featuring a prominently displayed shaft that is 22 inches long. |

| Honda BF90 | Honda | 20 | A robust, dark gray Honda BF90 outboard motor, showing its shaft extending 20 inches from the lower unit. |

| Mercury 115 | Mercury | 21 | A vibrant blue Mercury 115 outboard motor is shown, with its shaft measuring 21 inches in length. |

| Suzuki DF100 | Suzuki | 19 | A modern, red Suzuki DF100 outboard motor, highlighting a 19-inch shaft length. |

Interpreting the Shaft Length Chart

The table above provides a glimpse into the world of outboard motor shaft lengths. Each row represents a specific outboard motor model, along with its corresponding manufacturer and shaft length. The “Image Description” column helps visualize the shaft length within the context of the motor. Crucially, these values are critical for proper installation and operation.

Importance of Manufacturer Specifications

Referencing the manufacturer’s specifications is paramount. They provide precise data, meticulously measured under controlled conditions, unlike estimates or approximations. Using these exact specifications ensures the outboard motor and boat are perfectly matched. This meticulous attention to detail prevents potential issues, maximizing the performance and longevity of your investment. A mismatch in shaft length can lead to significant performance problems, from decreased fuel efficiency to severe damage.

Safety Precautions During Measurement

Don’t be a boating blunderbuss! Proper safety measures are crucial when handling outboard motors and tools, especially when taking precise measurements. A little precaution goes a long way in preventing potential mishaps and ensuring a smooth, safe measurement process.Careful consideration of safety protocols will transform your measurement session from a potential peril to a productive pursuit. Knowing the potential dangers and how to mitigate them is key to a safe and successful measurement endeavor.

Handling Outboard Motors Safely

Proper handling of outboard motors is paramount to prevent injury. Always ensure the motor is securely supported, ideally on a sturdy stand or workbench. Never attempt to lift or move a heavy motor by yourself. If assistance is needed, enlist help. Furthermore, ensure the motor’s fuel system is drained and the spark plug wire is disconnected to prevent accidental starting.

This crucial step will eliminate the risk of unexpected ignition.

Tool Safety Measures

Tools, like any other instruments, need respect. Using them improperly can lead to injuries. Always inspect tools for any damage before use. Ensure handles are firm and secure to prevent slippage. Make sure the tools are appropriate for the task at hand, as using the wrong tool can be hazardous.

Also, keep your workspace clean and organized to prevent tripping hazards. A well-maintained workspace minimizes the chances of accidents.

Measurement Procedure Safety Tips

To minimize risks during the measurement process, adhere to these safety tips:

- Always wear appropriate safety gear, including safety glasses or goggles to protect your eyes from flying debris and work gloves to protect your hands from sharp edges or potential cuts. Think of it as a safeguard against unexpected mishaps.

- Ensure the area around the measurement site is clear of obstructions and potential hazards. Clear pathways prevent unwanted collisions and accidents.

- Never attempt to measure while working under a boat or in confined spaces without proper support and ventilation. Always prioritize safety in confined spaces.

- If working near water, always use caution and take necessary precautions to avoid slips and falls. Never compromise safety for speed. Being mindful of your surroundings is crucial in watery environments.

- When using power tools, always follow the manufacturer’s instructions meticulously. Misusing power tools can lead to dangerous situations. Always prioritize the manufacturer’s recommendations.

Potential Hazards and Avoidance Strategies

Unforeseen dangers lurk in any measurement endeavor. Be aware of these hazards and their mitigation strategies.

- Sharp edges and corners: Always use protective gloves when handling components with sharp edges or corners to prevent cuts. A cut can disrupt your entire measurement process.

- Falling objects: Ensure secure support for the outboard motor and surrounding tools to prevent any potential falling objects. Prevent accidents by taking preventative measures.

- Electrical hazards: Disconnect the electrical system and ensure proper grounding before any work involving electrical components. Avoid any risk associated with electrical mishaps.

- Chemical hazards: Be mindful of any chemicals present and take necessary precautions, including proper ventilation and protective gear. Handle chemicals with respect.

Importance of Safety Gear

Appropriate safety gear is non-negotiable. It serves as a crucial barrier against potential hazards. Safety glasses and work gloves are just two examples of the safety gear you need. Wearing appropriate gear prevents injuries from minor scrapes to more severe accidents. It’s an investment in your safety and well-being.

Risks of Improper Tool Handling

Improper tool handling can lead to serious consequences. A damaged tool can malfunction, causing injury or even damage to the outboard motor. Misusing tools can lead to unforeseen hazards. Always ensure the tools are in good working order before use.

Final Summary

In conclusion, mastering the art of measuring your outboard motor shaft length empowers you to maintain optimal boat performance. By understanding the importance of precise measurements, utilizing the right tools and methods, and addressing potential issues, you can confidently navigate the complexities of boat maintenance. This guide provides a comprehensive resource for all your shaft measurement needs, guaranteeing a smooth and successful boating experience.

Q&A

What are the common mistakes to avoid when measuring shaft length?

Common mistakes include using worn or uncalibrated tools, neglecting environmental factors like temperature, and misinterpreting the manufacturer’s specifications. Always ensure your tools are in good condition and take steps to control environmental variables to achieve accurate results.

How can I tell if the shaft length is correct for my boat?

Consult the owner’s manual or the manufacturer’s specifications for your boat and outboard motor. A correct shaft length ensures the propeller and motor are correctly aligned with the hull, preventing potential issues like cavitation or damaged propellers.

What happens if I use an incorrect shaft length?

Using an incorrect shaft length can lead to performance issues, such as reduced speed, increased vibration, or propeller damage. It’s crucial to get the right length for optimal performance and the longevity of your outboard motor and propeller.

What is the importance of using calibrated measuring tools?

Calibrated tools provide accurate measurements, which are essential for ensuring proper compatibility between the outboard motor and the boat. Using tools that haven’t been calibrated could lead to inaccurate measurements, potentially causing issues with performance and longevity.