How to setup marlin firmware for einsy rentro 1.0a unlocks a world of 3D printing possibilities. This guide meticulously walks you through every step, from downloading the right firmware to configuring advanced settings. Prepare to transform your Einsy Rentro 1.0A into a precision printing powerhouse!

We’ll delve into the intricacies of Marlin firmware, highlighting its adaptability and the unique features of the Einsy Rentro 1.0A board. We’ll explore essential hardware components, and then guide you through the installation process, from downloading to verification, ensuring a seamless transition. Finally, we’ll delve into advanced configuration options, troubleshooting common problems, and optimizing your printer’s performance.

Introduction to Marlin Firmware and Einsy Rentro 1.0A

Marlin firmware is a powerful and widely used open-source firmware for 3D printers. It provides the essential control logic for various aspects of the printing process, from motor control and extruder movements to temperature regulation and bed leveling. Its modular structure and extensive customization options make it a popular choice for hobbyists and professionals alike.The Einsy Rentro 1.0A is a compact and feature-rich microcontroller board specifically designed for 3D printing applications.

Its small form factor and integrated hardware make it an attractive option for those seeking a powerful yet space-saving solution for their 3D printing setup. This board is designed for efficient communication and control, offering superior performance in a compact package.

Marlin Firmware Overview

Marlin firmware is a sophisticated platform for managing the complex processes involved in 3D printing. It orchestrates various actions such as controlling the stepper motors that move the print head, managing the heating elements for the bed and nozzle, and monitoring the progress of the print. Its open-source nature allows for extensive modification and customization, catering to a wide range of 3D printer designs and requirements.

Einsy Rentro 1.0A Features

The Einsy Rentro 1.0A board is a powerful and versatile platform for 3D printing. It integrates essential components like a robust microcontroller, necessary communication interfaces, and power management circuitry, all within a compact package. Its architecture is optimized for efficient data transfer and processing, allowing for smooth and reliable 3D printing operations. Key features include a high-performance processor, extensive memory capacity, and comprehensive communication protocols.

Essential Hardware Components for Installation

A successful Marlin firmware installation on the Einsy Rentro 1.0A requires several key hardware components. These components are crucial for establishing the necessary communication and power channels. Proper connection and configuration of these components ensure a stable and efficient printing experience.

- Power Supply: A stable power supply is essential to provide consistent power to the Einsy Rentro 1.0A board and the connected 3D printer components. Adequate power is crucial to prevent overheating and malfunctions during operation. A power supply rated for the combined power requirements of the printer and the Einsy Rentro 1.0A is highly recommended.

- Connecting Cables: Proper wiring is paramount for connecting the Einsy Rentro 1.0A to the 3D printer’s stepper motors, extruder, and other necessary components. Carefully adhering to the wiring diagrams and ensuring proper polarity are crucial for stable operation.

- 3D Printer: The 3D printer itself, with its associated mechanical components like the frame, hotend, and bed, forms the physical foundation of the printing setup. The 3D printer’s design must be compatible with the Einsy Rentro 1.0A board’s capabilities.

Marlin Firmware Compatibility

The table below highlights the compatibility of different Marlin firmware versions with the Einsy Rentro 1.0A. It’s crucial to select a version that is specifically optimized for this board to avoid compatibility issues.

| Marlin Version | Compatibility with Einsy Rentro 1.0A | Notes |

|---|---|---|

| Marlin 2.0.x | Likely Compatible | Requires checking for specific updates and configuration guidelines. |

| Marlin 2.0.x (Specific Release) | Potentially Compatible | May need additional configuration or updates for optimal performance. |

| Marlin 1.x.x | Possibly Incompatible | Older versions might lack support for specific features or communication protocols found on the Einsy Rentro 1.0A. |

Downloading and Installing the Necessary Files

Embarking on the journey of configuring your Einsy Rentro 1.0A with Marlin firmware necessitates meticulous attention to detail in downloading and installing the correct files. The precise version of Marlin is crucial for optimal performance and compatibility with your specific board. Carefully selecting the correct files ensures a smooth installation process and prevents potential issues down the line.The process of acquiring and installing the Marlin firmware involves navigating through various repositories and selecting the correct version for your specific Einsy Rentro 1.0A board.

This meticulous approach ensures compatibility and avoids common pitfalls encountered by newcomers to 3D printing firmware installations.

Identifying the Correct Marlin Firmware Version

The correct Marlin firmware version is paramount for seamless operation with your Einsy Rentro 1.0A. Mismatched firmware versions can lead to erratic behavior, printing errors, and even damage to your printer. To determine the correct version, consult the official Marlin firmware repository, specifically for the Einsy Rentro 1.0A. Check the release notes for any critical updates, bug fixes, or compatibility enhancements.

Often, newer versions include improvements in performance and stability.

Locating the Firmware File and Supporting Files

The Marlin firmware for the Einsy Rentro 1.0A, along with necessary supporting files, can be found on the official Marlin GitHub repository. This repository serves as a centralized location for the latest versions of Marlin, enabling access to crucial updates and enhancements. Look for a specific release branch tailored for your Einsy Rentro 1.0A.

Necessary Files and Their Purpose

The installation process involves several files with specific functions. A well-structured approach to understanding these files simplifies the installation process.

| File Name | Purpose | Expected File Extension |

|---|---|---|

| Marlin Firmware | The core firmware file that governs the operation of the 3D printer. | .bin |

| Configuration Files | Files that contain printer-specific settings, such as the dimensions of the print bed, extruder settings, and other critical parameters. | .cfg, .ini |

| Drivers | Crucial files that facilitate communication between the board and the printer’s components. | .h, .c, .cpp |

| Support Files (e.g., Libraries) | Additional libraries or files that extend the functionality of the Marlin firmware. | .h, .cpp, .c, .lib |

Preparing the Einsy Rentro 1.0A Board

The Einsy Rentro 1.3A board, a crucial component in your 3D printing endeavor, needs meticulous preparation before installing the Marlin firmware. This stage ensures the board’s readiness for the firmware and guarantees a seamless installation process. Proper connection and configuration are essential to prevent errors and ensure optimal performance.Careful attention to detail during this phase is paramount. Correct wiring and settings are vital for successful firmware operation.

Misconfigurations can lead to unexpected behaviors and potentially damage the board. This section details the necessary steps to prepare your Einsy Rentro 1.0A board for the Marlin firmware installation.

Power Supply Connection

The Einsy Rentro 1.0A requires a stable and adequate power supply. Insufficient voltage or erratic power delivery can lead to firmware instability or even damage the board. Connect the power supply’s positive (+) and negative (-) terminals to the corresponding pins on the board. Ensure proper polarity; incorrect polarity can damage the board’s components. Use a regulated power supply for stable operation.

USB Connection

A reliable USB connection is critical for communication between the computer and the Einsy Rentro 1.0A board during the firmware installation process. The USB cable should be compatible with the board and the computer. Ensure the cable is properly seated in both the board and the computer’s USB port.

USB Connection Settings

Specific settings are required for the USB connection to function correctly. The USB connection needs to be configured as a serial port. The required baud rate is typically 115200. This setting is crucial for the computer to correctly communicate with the board. Failure to configure the USB connection properly can result in communication errors during the installation process.

Verification of Connections

Thorough verification of all connections is critical before proceeding with the installation. Double-check the power supply connections, ensuring the correct polarity is observed. Verify the USB cable is securely plugged into both the board and the computer. Confirm the correct USB configuration settings. This meticulous verification step is essential to ensure the board is properly prepared for the installation process, preventing potential errors and ensuring a smooth operation.

Uploading the Firmware to the Einsy Rentro 1.0A

The Einsy Rentro 1.0A, a versatile and compact 3D printer controller, requires the meticulous installation of Marlin firmware for optimal performance. This crucial step empowers the board with the necessary instructions for executing complex printing tasks. A successful firmware upload ensures your printer can translate digital designs into tangible reality.This section delves into the process of uploading the Marlin firmware, outlining the necessary tools, methods, and potential pitfalls to guide you through this critical stage.

Understanding these nuances ensures a smooth transition from preparation to a fully functional 3D printing system.

Methods for Uploading Marlin Firmware

The Einsy Rentro 1.0A, like many Arduino-compatible boards, utilizes various methods for uploading custom firmware. The most common and straightforward approach involves utilizing the Arduino IDE.

Using the Arduino IDE

The Arduino Integrated Development Environment (IDE) provides a user-friendly interface for uploading the Marlin firmware. This method, widely adopted for its simplicity and accessibility, is detailed below. Connect your Einsy Rentro 1.0A to your computer using a USB cable. Open the Arduino IDE, select the correct board (Einsy Rentro 1.0A), and the appropriate port that corresponds to the connected board.

Load the Marlin firmware into the Arduino IDE. Verify the code to ensure there are no syntax errors. Finally, click the “Upload” button. The IDE will then transmit the code to the board, overwriting the existing firmware with the Marlin code.

Potential Issues During Upload

A successful firmware upload hinges on meticulous preparation and adherence to the established protocols. Several issues can impede the process.

- Incorrect Board Selection: Misselecting the board type in the Arduino IDE can lead to incompatibility issues and a failed upload. Double-check the board selection within the Arduino IDE to match the specific Einsy Rentro 1.0A board you’re using.

- Incorrect Port Selection: The Arduino IDE needs to identify the correct serial port connected to your Einsy Rentro 1.0A board. Selecting the wrong port will prevent the firmware from uploading. Use the Device Manager in Windows or similar utilities in other operating systems to verify the correct port is selected.

- USB Connection Problems: A weak or unstable USB connection can disrupt the upload process. Ensure a secure connection between the Einsy Rentro 1.0A and your computer’s USB port. A bad cable can also cause issues.

- Power Issues: The Einsy Rentro 1.0A may not receive sufficient power, hindering the upload. Ensure the board is properly powered and that the USB connection provides enough current.

- Code Errors: Errors in the Marlin firmware code, like typos or missing semicolons, can halt the upload process. Thoroughly review the uploaded code for any errors before initiating the upload. Carefully review and debug the Marlin code for any potential errors. Verify the compatibility of the Marlin version with your specific Einsy Rentro 1.0A board.

- Incompatible Hardware: Certain hardware configurations, such as incompatible shields or other components, can interfere with the upload process. Verify the compatibility of all components connected to the Einsy Rentro 1.0A board.

Troubleshooting

Troubleshooting steps are crucial in overcoming upload challenges. Verify the correct USB connection and check for any hardware conflicts. Ensure that the Marlin firmware is compatible with your specific Einsy Rentro 1.0A board. Carefully check the Arduino IDE settings and confirm that the correct port and board are selected.

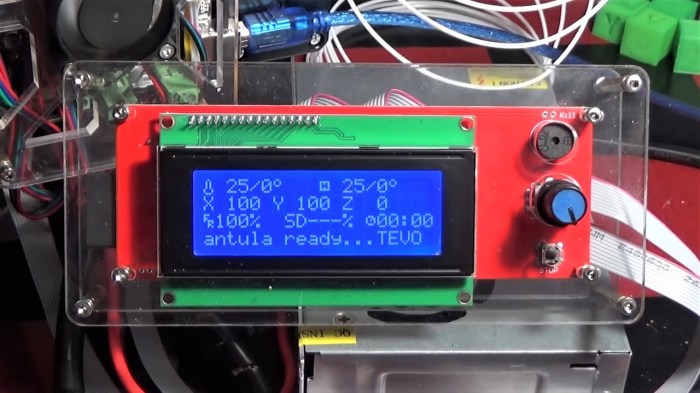

Verifying the Installation

The successful installation of Marlin firmware is crucial for the proper operation of your Einsy Rentro 1.0A. This phase involves rigorous testing to ensure the firmware interacts seamlessly with the hardware, leading to a reliable 3D printing experience. This section details the critical procedures for verifying the Marlin firmware’s functionality.Thorough verification ensures that the board operates as intended, addressing any potential issues before they impact your 3D printing workflow.

By executing the Artikeld tests, you guarantee the stability and accuracy of your 3D printing setup.

Testing Communication

Establishing communication between your computer and the Einsy Rentro 1.0A is paramount. Proper communication is vital for successful firmware control.The communication process, crucial for firmware control, must be tested for reliability. Failure to confirm communication may result in the inability to control the printer.

- Connecting to the Board: Ensure a stable connection between your computer and the Einsy Rentro 1.0A using a USB cable. This connection is essential for the firmware to receive instructions and send data.

- Using a Terminal Application: Employ a terminal application like Arduino IDE or a similar tool to establish a connection. This application allows you to send commands and observe the board’s responses, confirming the firmware’s responsiveness.

- Sending Test Commands: Input basic commands into the terminal, such as checking the firmware version or querying the current status. Monitoring the board’s response confirms communication and establishes a foundation for more complex operations. Example: `M115` (reports printer status).

Checking Movement and Motor Control

The ability to control the motors is fundamental to 3D printing functionality.Verifying the accuracy of motor control ensures the printer can execute the movements required for 3D printing. Inaccurate movements result in incorrect printing.

- Jogging the Motors: Initiate the jog mode in the terminal application. This allows you to manually move the axes (X, Y, Z) and observe the motors’ response. Smooth and responsive movement indicates the firmware and hardware are interacting correctly.

- Monitoring Movement Accuracy: Observe the movement of the printer’s axes using visual cues, such as the physical movement of the components. This provides a visual confirmation of the firmware’s ability to accurately control the motors.

Monitoring Board Status

Real-time monitoring of the board’s status provides insight into the firmware’s operation.Regular monitoring is essential to maintain control of the 3D printing process. Monitoring allows you to detect issues early and implement corrective actions.

- Monitoring Temperature Sensors: Confirm the firmware is correctly reading temperatures from the hotend and bed. Temperature readings are critical for consistent 3D printing quality. Incorrect readings indicate potential problems with the temperature sensors or the firmware’s ability to read them.

- Using a Visualization Tool: Use a visualization tool or monitor to track the real-time status of the board. This allows you to identify any unexpected behavior or issues in the firmware’s performance. The visual representation of the data assists in rapid problem identification and resolution.

Analyzing Output and Logs, How to setup marlin firmware for einsy rentro 1.0a

Examining the output and logs provides valuable insights into the firmware’s operation.Careful analysis is crucial to understand the firmware’s behavior. By reviewing logs and output, you can identify and correct potential errors or discrepancies in the system.

- Checking for Error Messages: Review any error messages or warnings from the terminal application. These messages can provide crucial clues to identify problems with the firmware or the hardware.

- Analyzing Log Files: If available, analyze any log files generated during the tests. These files can provide comprehensive information about the firmware’s behavior, enabling a detailed analysis of its performance.

Configuration and Customization

Marlin firmware, while providing a robust foundation, empowers users to tailor its settings to their specific 3D printer. This process unlocks performance optimization and ensures seamless integration with diverse hardware configurations. Understanding the configuration options available within Marlin is key to achieving the desired print quality and efficiency. Through careful parameter adjustments, users can fine-tune the printer’s behavior to match their particular needs and improve the overall printing experience.

Essential Configuration Options

Marlin’s configuration file, usually located within the `/Marlin/Configuration.h` folder, is a treasure trove of customizable settings. These settings dictate virtually every aspect of the printer’s operation, from motor speeds to bed temperatures. Understanding and correctly applying these parameters can dramatically affect print quality and reliability.

- Printer Dimensions: Accurate printer dimensions are critical for proper G-code generation and accurate movements. Incorrect values can lead to misaligned prints or collisions.

- Stepper Motor Settings: Defining the correct motor type and driver parameters is essential for smooth operation and optimal performance. This includes choosing the correct motor microstepping mode.

- Bed Size and Shape: Defining the exact size and shape of the print bed allows the printer to precisely position parts. Mismatched values will lead to errors in print placement and possible collisions.

- Z-Offset Calibration: This crucial setting adjusts the Z-axis to ensure the nozzle is positioned correctly above the print bed. Inaccurate Z-offset calibration leads to poor adhesion and inconsistent print quality.

- Probe Settings: Calibration settings for the bed probe allow the printer to accurately detect the bed’s surface. Incorrect values result in inconsistent bed leveling and potentially damaged parts.

Adjusting Parameters for Specific Needs

The flexibility of Marlin firmware lies in its ability to adapt to specific needs. For example, a user might need to increase the acceleration rate for a particular print if it’s too slow or decrease it for delicate materials to avoid warping. These adjustments, while seemingly small, can drastically impact the success and quality of a print.

- Printing Speed: Increasing or decreasing the print speed is often required for various material types or user preferences. Experimentation with different speeds helps users discover the optimal speed for their specific needs.

- Acceleration: Adjusting acceleration values enables the printer to react quickly and smoothly to changes in direction. Too low an acceleration rate can result in jerky movements, while too high a rate might lead to oscillations and poor quality.

- Retraction Settings: These settings manage filament retraction during pauses in the print process. Adjustments are vital for preventing stringing and ensuring consistent print quality.

Configuring Different Stepper Motors

Stepper motor configurations are vital for smooth and reliable operation. The correct settings for each motor type are essential for the desired performance.

- Motor Type Identification: Correctly identifying the stepper motor type is fundamental to selecting the appropriate driver settings and minimizing potential damage. The correct motor type identification is a prerequisite for correct settings.

- Microstepping Configuration: Setting the appropriate microstepping mode (e.g., full, half, 1/8, 1/16) optimizes the motor’s precision and smoothness. The selected microstepping mode determines the level of detail the printer can achieve.

- Driver Settings: Adjusting the driver settings, like current, steps per revolution, and stall detection, fine-tunes the motor’s response and performance. Correct driver settings minimize the risk of motor burnout and maximize the printer’s efficiency.

Troubleshooting Common Issues

Marlin firmware installation, while often straightforward, can present unexpected hurdles. This section delves into common problems encountered during the setup process, focusing on effective solutions for uploading, connection, and communication issues. Understanding these potential roadblocks empowers you to diagnose and resolve them efficiently, ensuring a smooth and successful installation.

Uploading Issues

Firmware upload failures are a frequent concern. Several factors can contribute to these failures, ranging from hardware glitches to software incompatibilities. A meticulous examination of potential causes is crucial for resolving these problems.

- Connection Errors: A weak or unstable connection between your computer and the Einsy Rentro 1.0A board can cause upload interruptions. Ensure a stable USB connection and check for potential interference from other devices on your system. Try a different USB port if possible. Confirm the USB connection is firmly seated in both the board and the computer.

- Incorrect Communication Port: Selecting the wrong COM port during the upload process can lead to errors. Ensure the correct COM port is selected in your chosen firmware uploading software. The COM port number will vary depending on your system configuration.

- Corrupted Firmware File: A damaged or corrupted Marlin firmware file will prevent a successful upload. Download the firmware file again from a trusted source to verify its integrity. Check the file size to ensure it matches the original.

- Hardware Problems: Issues with the Einsy Rentro 1.0A board itself, such as a faulty USB port or microcontroller, can cause upload problems. If other USB devices are working fine, the issue likely lies with the board.

Connection and Communication Problems

Stable communication between the computer and the Einsy Rentro 1.0A board is essential for successful firmware uploads and subsequent operation. Problems in this area can manifest in various ways, necessitating a systematic approach to identify the root cause.

- Driver Conflicts: Incompatible or outdated USB drivers can disrupt communication between your computer and the board. Ensure that the correct drivers are installed and updated to the latest versions available from the Einsy Rentro 1.0A manufacturer.

- Power Issues: Insufficient or fluctuating power supply to the Einsy Rentro 1.0A can disrupt communication. Ensure a stable power source for the board and monitor power levels during the upload process.

- Overclocking Problems: If the Einsy Rentro 1.0A board’s clock speed is set too high, it might not communicate properly with the computer. Ensure the clock speed is correctly configured and optimized for your system.

- Troubleshooting Software Issues: Errors within the chosen firmware uploading software can cause upload problems. Restarting the software or checking for updates might resolve these issues.

Example Errors and Potential Causes

Identifying the specific error message encountered can provide valuable clues to the underlying problem. Analyzing these error messages is a crucial step in isolating the cause of the issue.

| Error Message | Potential Cause |

|---|---|

| “Upload Failed” | Possible connection problems, incorrect COM port selection, corrupted firmware file, or hardware issues. |

| “Communication Error” | Driver conflicts, power issues, or problems with the communication protocol between the computer and the board. |

| “Invalid Command” | Incorrect firmware file or mismatched hardware configuration. |

Advanced Configuration Options

Unlocking the full potential of your Einsy Rentro 1.0A printer requires delving into advanced Marlin firmware configurations. This section explores customization options, allowing you to tailor the printer’s behavior to your specific needs and printer type. From optimizing print speeds to fine-tuning sensor responses, these adjustments are crucial for achieving optimal print quality and reliability.Understanding the intricacies of Marlin’s configuration files is paramount.

These files contain a wealth of parameters governing the printer’s actions, from motor speeds to extruder temperatures. Modifying these values empowers you to fine-tune the printer for different filament types and print materials, ultimately optimizing the printing process.

Customizing for Specific Printer Types

Marlin supports a wide range of 3D printers. To ensure optimal performance, configuring Marlin for your particular printer model is essential. This involves adjusting parameters specific to your machine’s dimensions, mechanics, and sensor types. Comprehensive documentation for your printer model should be consulted for precise adjustments.

Optional Feature Configuration

Certain features are not enabled by default in Marlin. This section details how to activate these features and configure them to suit your needs. Activating features such as automatic bed leveling, or more complex filament handling can drastically improve the print quality and user experience.

- Automatic Bed Leveling: This feature automatically adjusts the Z-axis to compensate for variations in the build plate. Configuring it requires specifying the bed leveling method (e.g., probe type, offset, and number of points), and the algorithm for leveling. This feature enhances consistency in print quality and minimizes warping.

- Advanced Filament Handling: For printers with advanced filament systems, configuration parameters control features like filament sensor integration, filament runout detection, and custom filament change procedures. These allow for greater automation in filament management and reduced print interruptions.

- Custom G-code Macros: Complex print operations or custom actions can be streamlined through custom G-code macros. These macros allow you to automate sequences of commands, enabling greater precision and efficiency. Customizing these macros can save valuable time during complex printing processes.

Sensor Configuration Options

Different sensor types (e.g., probes, limit switches, and filament sensors) require specific configuration within Marlin. Proper configuration ensures accurate readings and reliable operation.

- Z-axis Probe: Configure the probe type (e.g., inductive, capacitive), its calibration procedure, and its placement relative to the print bed. This ensures accurate bed leveling and consistent print quality.

- Limit Switches: Configure the pin assignments for limit switches on the X, Y, and Z axes. This ensures the printer stops safely when encountering physical barriers. Correct configuration prevents damage to the printer and ensures safe operation.

- Filament Sensors: For printers with filament sensors, configuring the sensor type and pin assignment is crucial. This ensures reliable detection of filament changes and prevents interruptions in the print process.

Customizing Printer Behavior

The Marlin firmware allows you to customize the printer’s behavior based on your specific needs. This includes adjustments to print speeds, acceleration profiles, and extruder settings.

- Print Speeds and Acceleration Profiles: Adjusting print speeds and acceleration profiles allows for optimizing the balance between print speed and quality. Careful adjustment can reduce print time without sacrificing print accuracy.

- Extruder Settings: Customizing extruder settings, such as flow rate, extrusion multiplier, and temperature settings, allows for optimization of the filament extrusion process, improving print quality and consistency.

Illustrative Examples and Best Practices: How To Setup Marlin Firmware For Einsy Rentro 1.0a

Mastering Marlin firmware involves more than just installation; it’s about tailoring it to your specific printer and optimizing its performance. This section provides practical examples, best practices for maintenance, and optimization strategies to unlock the full potential of your Einsy Rentro 1.0A.Proper configuration, alongside meticulous maintenance, ensures a smooth printing experience and longevity for your 3D printer.

Marlin Firmware Configuration Examples

Configuration settings are crucial for printer performance. Here are examples of key settings and their impact:

- Stepper Motor Tuning: Adjusting the `steps_per_mm` parameter is fundamental. A typical value for a standard 1.8 degree stepper motor might be 200 steps per revolution. Multiply this by the gear ratio of your extruder and drive train to calculate the correct value for your printer. For instance, if your extruder has a 3:1 gear ratio, the steps_per_mm would be 600.

Incorrect settings can lead to inaccurate movements and skipped layers. This careful tuning ensures precision in every print.

- Z-Axis Calibration: Precise Z-axis calibration is vital for layer adhesion. The `z_offset` parameter allows you to adjust the Z-axis to compensate for inconsistencies in the bed and nozzle height. By meticulously measuring the distance between the nozzle and bed, you can find the optimal `z_offset` value. A value of 0.1mm or 0.2mm can drastically improve print quality.

- Bed Temperature: The `bed_temperature` setting is critical for adhesion and print quality. For PLA, a common temperature range is 60-70°C. Different filaments require specific temperatures, so always consult the filament manufacturer’s recommendations. Incorrect bed temperature can lead to warping, adhesion issues, or uneven prints.

Best Practices for Marlin Firmware Maintenance

Regular maintenance is essential to maintain print quality and prevent issues.

- Firmware Updates: Regularly check for Marlin firmware updates to leverage bug fixes and new features. Updates often include performance enhancements and compatibility improvements for various 3D printers. Outdated firmware might not be compatible with your hardware, or it might have vulnerabilities.

- Backup Copies: Always create a backup of your current Marlin firmware configuration before making any modifications. This ensures you can revert to a known working state if something goes wrong during customization. Losing your configuration is a significant setback.

- Documentation: Maintain detailed records of any modifications made to the Marlin firmware. Note changes to settings and their impact on print quality. This documentation will help you understand and troubleshoot issues in the future. Proper documentation allows for easier problem-solving.

Optimizing Printer Performance

Several strategies optimize printer performance, contributing to higher print quality and reduced errors.

- Print Quality and Settings: Experiment with different print settings, such as layer height, infill density, and nozzle temperature, to find the optimal settings for your filament and printer. This meticulous approach ensures the best print quality. Print quality is heavily influenced by these factors.

- Troubleshooting and Calibration: Thoroughly examine and calibrate your printer regularly to identify and fix potential issues, such as misaligned axes or inconsistencies in the nozzle. This methodical approach prevents future problems.

- Regular Maintenance: Clean the nozzle and bed regularly to remove filament build-up. This prevents clogging and ensures smooth operation. Regular maintenance is key to maintaining print quality.

Comparison of Firmware Settings and their Effects

| Setting | Effect on Printer Performance |

|---|---|

| `steps_per_mm` | Impacts accuracy of movements, affects layer adhesion, potential for skipping layers. |

| `z_offset` | Adjusts Z-axis height for proper bed adhesion, preventing warping and ensuring consistent layers. |

| `bed_temperature` | Affects filament adhesion and bed warping. Incorrect temperature can lead to failed prints or damage. |

Summary

Mastering Marlin firmware on your Einsy Rentro 1.0A opens up a universe of customization and control over your 3D printing experience. This guide equips you with the knowledge and practical steps to successfully install and configure your firmware, unleashing the full potential of your printer. From basic setup to advanced tuning, this comprehensive guide is your key to 3D printing excellence.

Questions and Answers

What specific software is needed besides the Arduino IDE?

While the Arduino IDE is crucial, additional tools like a terminal or a dedicated firmware uploading utility might be helpful depending on your specific setup.

What if I encounter a “communication error” during the upload?

Check your USB connection, ensure the board is properly powered, and verify the correct firmware version for your board. Also, verify the USB port and drivers are compatible.

How do I adjust the print speed for different materials?

Marlin firmware offers customizable parameters for print speed and acceleration. Experiment with different values, taking into account the material’s characteristics, and monitor the print quality.

Are there any specific troubleshooting steps for a “connection timeout” error?

Ensure the board is correctly powered and connected. Check for conflicting software or hardware conflicts. Try using a different USB port and/or cable.