With how to use 3 s[eed shifter on 2 speed, this perilous journey into the intricacies of mechanical marvels begins. Imagine the daunting task of coaxing a three-speed transmission into a two-speed machine. It’s a feat demanding precision, understanding, and a dash of bravery. This guide will illuminate the path, revealing the secrets to navigating this mechanical labyrinth, from the fundamental differences in gear ratios to the intricate steps of the shift mechanism.

Delving into the specifics, this exploration unveils the critical distinctions between two- and three-speed transmissions, emphasizing the applications where the added complexity of a three-speed system is indispensable. We will systematically break down the components, procedures, and potential pitfalls, arming you with the knowledge to conquer this technical challenge. Understanding the nuances of shifting, troubleshooting common issues, and maximizing performance will all be covered.

Introduction to 3-Speed Shifters

Two-speed transmissions offer a limited range of gear ratios, primarily suited for applications with predictable operating conditions. This limited range often results in reduced fuel efficiency and performance compared to transmissions with more options. Three-speed transmissions, in contrast, provide an intermediate step, increasing the range of gear ratios available and enhancing both efficiency and performance.Three-speed transmissions are prevalent in various applications where a compromise between complexity, cost, and performance is sought.

Examples include small-scale agricultural equipment, light commercial vehicles, and certain recreational vehicles. Compared to the simpler two-speed designs, the added complexity of a third gear allows for improved fuel economy at various speeds and a wider range of operating conditions.

Fundamental Differences Between 2-Speed and 3-Speed Transmissions

A 2-speed transmission typically offers a low gear for acceleration and a high gear for cruising. This simplicity comes at the cost of efficiency in intermediate speed ranges. A 3-speed transmission, however, incorporates an additional gear, creating a more balanced set of ratios. This additional gear optimizes performance across a wider range of speeds.

Applications of 3-Speed Transmissions

Three-speed transmissions are commonly used in applications demanding a balance between cost-effectiveness and performance. This includes:

- Small-scale agricultural equipment: Tractors, and other equipment requiring power for various tasks, benefit from the added flexibility of a 3-speed transmission. The intermediate gear allows for smoother operation at intermediate speeds, improving fuel economy and reducing wear and tear.

- Light commercial vehicles: Delivery vans, small trucks, and similar vehicles benefit from the increased efficiency and wider operating range offered by the third gear. This enables better fuel economy during typical driving conditions.

- Recreational vehicles: RVs, ATVs, and similar vehicles benefit from a 3-speed transmission for a balance between power and fuel efficiency. The intermediate gear allows for better performance in varied terrains and speeds, making them more versatile for their intended use.

General Principles of Operation

A 3-speed transmission operates on the principle of gear ratios. Each gear corresponds to a specific gear ratio, which determines the output speed relative to the input speed. A higher gear ratio results in a lower output speed for a given input speed, leading to higher torque and lower rotational speed. Conversely, a lower gear ratio results in a higher output speed and lower torque.

Gear Ratios of a Typical 3-Speed Transmission

The following table illustrates a typical gear ratio setup for a 3-speed transmission. The specific ratios may vary depending on the application and design specifications.

| Gear | Ratio | Description |

|---|---|---|

| 1 | 2.50:1 | Low gear; provides high torque for starting and climbing hills |

| 2 | 1.50:1 | Intermediate gear; suitable for moderate speeds and loads |

| 3 | 1.00:1 | High gear; provides maximum speed with lower torque |

Understanding the 3-Speed Shift Mechanism

A 3-speed shifter, compared to its 2-speed counterpart, offers greater flexibility and control over vehicle speed and acceleration. Understanding the physical components and precise shifting procedure is key to maximizing its performance and preventing damage. This section details the inner workings of a 3-speed transmission.The mechanism behind a 3-speed shifter is a complex interplay of levers, gears, and linkages.

Each position of the shifter corresponds to a specific gear, enabling the engine’s power to be transmitted to the wheels with varying degrees of speed and torque. Proper shifting is crucial for both optimal performance and the longevity of the transmission.

Physical Components of a 3-Speed Shifter

The 3-speed shifter mechanism comprises several crucial parts working in concert. These include the shifter lever, a series of gears (typically within the transmission housing), and a set of linkage components that translate the shifter’s movement into gear changes within the transmission. The shifter lever, usually located on the dashboard or console, is the primary point of user interaction.

The internal gears and linkages are designed to precisely align and disengage various gears, facilitating seamless shifting between the three gears.

Steps Involved in Shifting Through the Three Gears

Shifting through the gears involves a specific sequence of actions. First, the driver must identify the desired gear position on the shifter. Second, the driver must carefully move the shifter lever to the corresponding position, which engages the specific gear. Third, the transmission automatically connects the engine’s power to the wheels via the selected gear. Finally, the driver must confirm that the gear is correctly engaged and the vehicle is operating as expected.

Proper technique and attention to detail are crucial for smooth transitions between gears.

Lever Positions for Each Gear

The shifter lever exhibits distinct positions for each gear. These positions are typically marked on the shifter itself. Accurate positioning is essential for seamless transitions between gears and avoiding potential damage to the transmission.

Gear Selection Table

The following table illustrates the different lever positions and their corresponding gear selections:

| Gear | Lever Position | Description |

|---|---|---|

| Neutral (N) | Central position | The engine is not driving the wheels, allowing the vehicle to be moved by the driver (e.g., pushing or towing). |

| First Gear (1) | Lowermost position | Provides maximum torque for starting and accelerating from a standstill. |

| Second Gear (2) | Intermediate position | Provides a higher speed than first gear, suitable for moderate acceleration and highway driving. |

| Third Gear (3) | Uppermost position | Provides the highest speed, typically used for highway driving. |

Troubleshooting Common Issues

Proper operation of a 3-speed shifter relies on a well-maintained and functioning system. Troubleshooting issues like sticking gears, noisy operation, or difficulty shifting is crucial for optimal performance. This section details potential problems, their causes, and effective troubleshooting procedures.Troubleshooting a 3-speed shifter involves systematically identifying the source of the problem. A methodical approach, focusing on each component of the system, is essential for efficient and accurate diagnosis.

A common mistake is attempting to address a problem without first identifying its root cause. Understanding the relationship between various parts of the mechanism is vital to successful troubleshooting.

Identifying Sticking Gears

Sticking gears are a common issue in 3-speed shifters. This can manifest as resistance or difficulty engaging a particular gear, or the gear remaining engaged even after shifting. Factors such as worn gears, binding components, or damaged linkage can lead to this problem. A thorough inspection of the shifter components is essential.

Diagnosing Noisy Operation

A noisy shifter can indicate problems with the gear teeth, linkage, or bearings. The sound can range from grinding noises to clicking or rattling sounds. These noises often signal the presence of friction or wear, which, if left unaddressed, can lead to more severe damage. Careful attention to the source of the noise is critical.

Assessing Shifting Difficulty

Difficulty shifting can be attributed to several factors, including worn components, incorrect lubrication, or bent linkage. A thorough inspection, focusing on the condition of the gears, shift mechanism, and linkage, can pinpoint the specific cause.

Troubleshooting Procedure

- Visual Inspection: Carefully examine the shifter components for any visible damage, wear, or misalignment. This includes the gears, shift lever, linkage, and all associated parts.

- Lubrication Check: Ensure that all moving parts are adequately lubricated. Insufficient lubrication can cause friction and resistance during shifting. Pay particular attention to the gear teeth, pivot points, and any moving linkages.

- Linkage Adjustment: Verify that the linkage is properly aligned and functioning correctly. Incorrect alignment can prevent smooth shifting and may require adjustment or repair.

- Gear Alignment Check: Inspect the gears for any damage, misalignment, or wear. Bent or damaged gears can prevent proper engagement and require replacement.

Troubleshooting Table

| Troubleshooting Step | Effectiveness | Potential Issue |

|---|---|---|

| Visual Inspection | High | Visible damage, misalignment |

| Lubrication Check | Medium | Insufficient lubrication |

| Linkage Adjustment | High | Incorrect alignment, bent linkage |

| Gear Alignment Check | High | Bent, damaged, or misaligned gears |

Comparison with 2-Speed Systems

A 3-speed transmission offers greater flexibility and control over vehicle performance compared to a 2-speed system. This enhanced range of speed options translates into improved fuel efficiency and handling capabilities in diverse driving conditions. Understanding the nuances of each system allows for informed decisions about vehicle suitability for specific applications.The core difference lies in the number of gear ratios available.

A 2-speed transmission provides two gear ratios, maximizing either acceleration or top speed, but limiting the overall performance range. Conversely, a 3-speed transmission offers three distinct gear ratios, allowing for a more comprehensive adjustment to different driving scenarios. This allows for a broader range of operating speeds, making it suitable for a wider variety of applications.

Performance Characteristics

The performance characteristics of a 3-speed transmission demonstrate significant advantages over a 2-speed transmission. A 3-speed transmission offers a more efficient range of speed options. This wider range translates to better fuel economy at various speeds. A 2-speed transmission often prioritizes either high-speed or low-speed performance, leading to suboptimal performance in the intermediate speed ranges.

Benefits of a 3-Speed System

A 3-speed system presents several advantages over a 2-speed system, primarily due to its wider range of gear ratios. This enables a smoother and more efficient transition between different driving conditions. This enhanced flexibility leads to improved fuel economy across various speeds. For instance, a 3-speed transmission allows for a more gradual acceleration from low to high speeds, optimizing engine performance and fuel consumption.

Drawbacks of a 3-Speed System

While a 3-speed transmission provides notable benefits, there are also potential drawbacks to consider. One drawback is the added complexity in design and manufacturing. This can result in a slightly higher cost compared to a 2-speed system. Furthermore, the additional gears might introduce slight reductions in overall efficiency in specific situations.

Situations Favoring a 3-Speed Transmission

A 3-speed transmission is particularly advantageous in situations requiring a wider range of speed options. For example, in applications where varying terrains or speed requirements necessitate a more adaptable transmission. Vehicles used in hilly areas or those needing to efficiently navigate varying road gradients benefit significantly from the 3-speed transmission’s adaptability.

Comparison Table

| Feature | 2-Speed Transmission | 3-Speed Transmission |

|---|---|---|

| Speed Ranges | Limited, optimized for high or low speeds | Wider range, covering a broader spectrum of speeds |

| Efficiency | Potentially less efficient in mixed-speed conditions | Generally more efficient due to adaptable gear ratios |

| Maintenance | Typically simpler, with fewer moving parts | Potentially more complex, with more moving parts |

| Cost | Usually lower due to simpler design | Generally higher due to more complex design |

Maintenance and Care

Proper maintenance is crucial for extending the lifespan of a 3-speed transmission and ensuring its smooth operation. Neglecting routine care can lead to premature wear, costly repairs, and potential safety hazards. This section details the necessary steps for lubricating and inspecting the components, highlighting the importance of regular maintenance.

Routine Maintenance Steps

Regular maintenance tasks are essential for the long-term health of a 3-speed transmission. These procedures help identify potential issues early, preventing more extensive and expensive repairs down the road. Consistent upkeep ensures reliable performance and optimal gear shifting.

- Cleaning the Transmission Housing: Regularly cleaning the transmission housing removes dirt, debris, and moisture buildup. This prevents corrosion and ensures smooth operation. Use a degreaser and a soft-bristled brush, taking care not to damage internal components.

- Lubrication: The transmission’s lubrication system is vital for smooth gear engagement and reduced friction. Regularly checking and replenishing the lubricant is crucial. Consult the manufacturer’s specifications for the correct type and amount of lubricant. Incorrect viscosity can lead to component damage.

- Gear Shift Mechanism Inspection: Inspect the gear shift mechanism for any signs of wear, damage, or binding. Smooth operation of the shift lever is critical. Ensure all linkages are properly aligned and lubricated. Any unusual noise or resistance should be addressed promptly.

- Component Inspection: Thoroughly inspect all visible components for signs of wear or damage, including the gears, shafts, bearings, and seals. This proactive inspection allows for timely repairs and prevents catastrophic failures.

Lubrication Procedure

Correct lubrication ensures smooth gear shifting and reduces wear on internal components. Improper lubrication can lead to significant damage. Following the manufacturer’s specifications is essential for optimal performance.

- Gather necessary tools and supplies: Ensure you have the correct type of lubricant, cleaning supplies, and appropriate tools for accessing the transmission.

- Locate the lubricant fill point: Refer to the manufacturer’s manual for the specific location of the fill point. Improperly locating the fill point can lead to lubricant overfill or underfill.

- Drain the old lubricant: If required by the manufacturer’s instructions, drain the old lubricant. Ensure the transmission is securely supported to prevent leaks.

- Add new lubricant: Carefully add the correct amount of new lubricant as specified by the manufacturer. Overfilling can cause issues.

- Verify the lubricant level: Ensure the lubricant level is within the recommended range. Use the manufacturer’s guide to determine the correct level.

Importance of Regular Maintenance

Regular maintenance significantly extends the life of the 3-speed transmission. By proactively addressing potential issues, you can avoid costly repairs and maintain optimal performance. Consistent upkeep is essential for reliability and preventing sudden failures.

- Prolongs Lifespan: Regular maintenance, including lubrication and inspection, prevents premature wear and tear, extending the overall lifespan of the transmission.

- Reduces Repair Costs: Early detection of issues through regular maintenance reduces the likelihood of major repairs. Catching problems early minimizes the potential for costly replacements.

- Ensures Reliability: Proactive maintenance ensures smooth and reliable operation of the transmission, minimizing downtime and improving overall performance.

- Improves Safety: A well-maintained transmission is safer to operate. Regular maintenance prevents potential failures that could lead to accidents.

Tools and Supplies

- Transmission lubricant

- Cleaning solvents

- Soft-bristled brush

- Torque wrench (if applicable)

- Gloves

- Drain pan

- Manufacturer’s manual

- Safety glasses

- Measuring cup

Practical Examples and Scenarios

Mastering a 3-speed shifter unlocks a wider range of operational possibilities, particularly in applications requiring variable speed control. Understanding the nuances of each gear is essential for optimizing performance and efficiency. This section delves into practical examples and scenarios where a 3-speed transmission is critical.A 3-speed transmission, compared to a 2-speed, provides greater flexibility in adjusting operating speed to match varying work conditions.

This increased control is particularly valuable in applications where precise speed adjustments are needed for optimal performance and productivity. This section provides practical examples and detailed gear selection processes for specific applications.

Small Agricultural Machine Example, How to use 3 s[eed shifter on 2 speed

This example illustrates the gear selection process for a small agricultural machine, such as a tiller. The machine’s 3-speed transmission allows for varied operating speeds depending on the task and terrain.

Consider a scenario where a farmer is tilling a field. The initial task may require a slower speed for meticulous soil preparation. In this case, the operator would select the first gear, providing the lowest speed and maximizing torque for effective tilling. As the work progresses, the ground may become more level, and a higher speed is necessary to maintain productivity.

The operator would then shift to second gear for a moderate speed, or even third gear for a higher speed to expedite the process. The appropriate gear selection directly influences the machine’s efficiency and the overall time required to complete the task.

Gear Selection Process for a Tiller

The gear selection process for a tiller, using the 3-speed transmission, is as follows:

- First Gear: Ideal for tasks requiring maximum torque and minimum speed, such as initial soil preparation, tilling in tight spaces, or working on uneven terrain.

- Second Gear: Suitable for maintaining a moderate speed while maintaining sufficient torque. This gear is often used for continuous tilling operations on relatively level ground.

- Third Gear: Provides the highest speed, minimizing time spent on the task. Appropriate for finishing operations on smooth terrain, where speed is a priority, but torque is not a significant factor.

Common Applications of 3-Speed Shifters

Understanding the versatility of a 3-speed transmission is crucial for selecting the right equipment for specific tasks.

- Small Agricultural Machinery: Tractors, tillers, and other small-scale agricultural implements often benefit from the increased control offered by a 3-speed transmission.

- Construction Equipment: Certain types of construction equipment, such as compact excavators or trenchers, can utilize 3-speed transmissions to adjust speeds for various excavation tasks.

- Industrial Machinery: Some industrial machinery, like conveyors or small power tools, may employ 3-speed transmissions to optimize operational efficiency and control.

- Gardening Tools: Power mowers and other gardening tools can use a 3-speed transmission for varying cutting speeds, depending on the type of grass or vegetation.

Advanced Techniques (Optional): How To Use 3 S[eed Shifter On 2 Speed

Optimizing a 3-speed transmission for peak performance requires understanding the interplay between gear ratios and operating conditions. This section delves into advanced techniques, providing strategies for achieving optimal efficiency and power delivery in various scenarios. These methods go beyond basic shifting and explore the nuances of maximizing the transmission’s capabilities.Advanced techniques for 3-speed transmissions involve more than just selecting the appropriate gear.

They involve anticipating the demands of the task and using the transmission to its fullest potential, rather than merely using it as a simple gear selector.

Gear Ratio Optimization

Understanding gear ratios is crucial for maximizing the 3-speed transmission’s efficiency. Different gear ratios provide varying levels of torque and speed. Choosing the right ratio for a given situation ensures the engine operates at its most efficient RPM range. A well-calibrated understanding of these ratios allows for precise control of acceleration and fuel consumption.

| Gear Ratio | Optimal Application | Description |

|---|---|---|

| Low Gear (1st) | Starting from standstill, steep inclines, heavy loads | Provides maximum torque for overcoming high resistance. |

| Intermediate Gear (2nd) | Moderate inclines, accelerating from low speeds | Balances torque and speed, suitable for most common driving conditions. |

| High Gear (3rd) | Level roads, high speeds | Provides maximum speed with minimal engine load, ideal for highway driving. |

Load Management Strategies

Managing the load on the transmission is essential for achieving peak performance. Heavy loads require the use of lower gears to prevent engine strain and potential damage. By matching the gear ratio to the load, the engine can maintain a healthy operating range.

- Anticipate Load Changes: Predicting changes in load, such as when encountering a hill or carrying a heavier payload, allows the driver to preemptively shift into the appropriate gear, ensuring smooth transitions and maximizing efficiency.

- Minimize Engine Stalling: Avoid sudden changes in load, especially when shifting to higher gears. This can cause the engine to stall if the load is too high for the gear.

- Smooth Acceleration: Gradual acceleration and controlled acceleration and deceleration in different gears will prevent transmission shock and improve overall performance.

Engine RPM Management

Engine RPM (Revolutions Per Minute) plays a critical role in transmission performance. Maintaining optimal RPMs in each gear ensures that the engine operates within its most efficient range, minimizing fuel consumption and maximizing power output.

Proper RPM management in each gear ensures the engine operates within its most efficient range, minimizing fuel consumption and maximizing power output.

Illustrative Diagrams

Visual representations are crucial for understanding the intricacies of 3-speed transmissions. They provide a clear, concise way to grasp the relationships between components and their functions, making the learning process significantly more effective. Diagrams illustrate the physical layout, motion sequences, and critical lever positions, aiding in the identification of potential issues and facilitating the correct execution of procedures.Visual representations are crucial for understanding the intricacies of 3-speed transmissions.

They provide a clear, concise way to grasp the relationships between components and their functions, making the learning process significantly more effective. Diagrams illustrate the physical layout, motion sequences, and critical lever positions, aiding in the identification of potential issues and facilitating the correct execution of procedures.

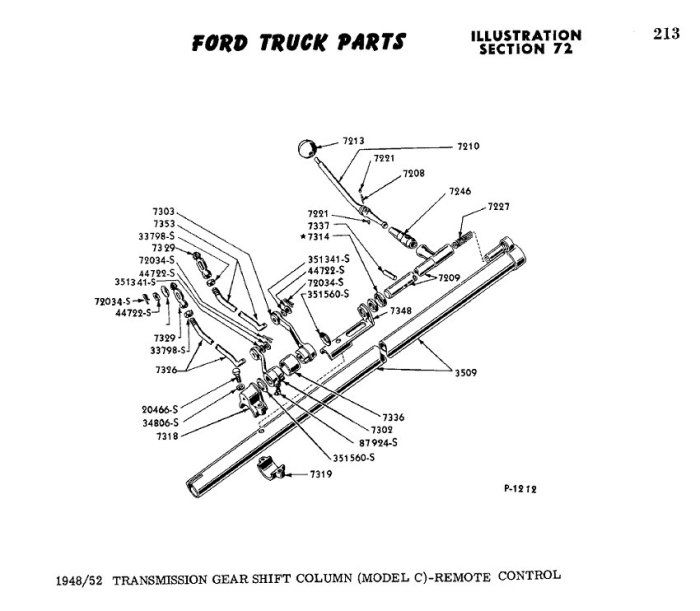

Typical 3-Speed Transmission Diagram

A typical 3-speed transmission employs a series of gears and shafts, connected through bearings and sprockets. The diagram should illustrate the gear arrangement, highlighting the primary shafts (input, intermediate, and output) and the associated gears. Clear labeling is essential to identify each gear’s position and function within the transmission. The diagram should depict the relative sizes and positions of the gears, showcasing how the gears mesh and engage.

This arrangement allows for a smooth transition between different speeds and torque levels.

Lever Positions for Each Gear

The diagram should show the lever positions corresponding to each gear. These positions are critical for selecting the correct gear and ensuring smooth shifting. The diagram should clearly delineate the different lever positions, showcasing the distinct mechanical configurations for each gear, with precise labels. This visual guide helps in understanding the mechanical relationship between the lever and the internal gear mechanism, enabling the user to accurately select the desired gear.

Shift Mechanism Path Diagram

This diagram visually depicts the path of the shift mechanism as it engages different gears. It should showcase the movement of components, such as forks, levers, and rods, as they connect and disengage different gears. The diagram should emphasize the sequence of actions during shifting, from one gear position to another. Illustrate the physical displacement of these components in relation to each other, as well as how the engagement of these parts enables the selection of different gear ratios.

3-Speed Shifter Mechanism Diagram

This diagram will provide a detailed view of the 3-speed shifter mechanism, focusing on the key components. It should showcase the lever, the internal linkages, the shift forks, and the detents that engage with the gears. The diagram should identify the critical components and explain their function within the shifting process. Highlight the engagement points and the precise manner in which the components interact to select the appropriate gear.

Clearly label each component to aid in understanding and troubleshooting.

Final Summary

In conclusion, harnessing the power of a three-speed shifter within a two-speed framework requires a deep understanding of its mechanics and a meticulous approach. This comprehensive guide has illuminated the path, equipping you with the knowledge to tackle this seemingly impossible task. From the initial stages of comprehension to the advanced techniques, you are now prepared to master this intricate system.

Remember, precision and meticulous care are paramount in this process.

Frequently Asked Questions

What are the common issues with a 3-speed shifter in a 2-speed application?

Sticking gears, noisy operation, and difficulty shifting are common problems. These often stem from improper lubrication, worn components, or misaligned linkages. Troubleshooting involves careful inspection of the shifter mechanism and related components.

What are the key differences between 2-speed and 3-speed transmissions in terms of performance?

A 3-speed system offers a wider range of speed options, potentially enhancing efficiency and performance in certain applications. However, it introduces additional complexity and potential maintenance needs compared to a simpler 2-speed system.

How often should I lubricate a 3-speed transmission?

Regular lubrication is crucial for optimal performance and longevity. Specific intervals depend on the type of transmission and operating conditions. Consult the manufacturer’s recommendations for your particular application.